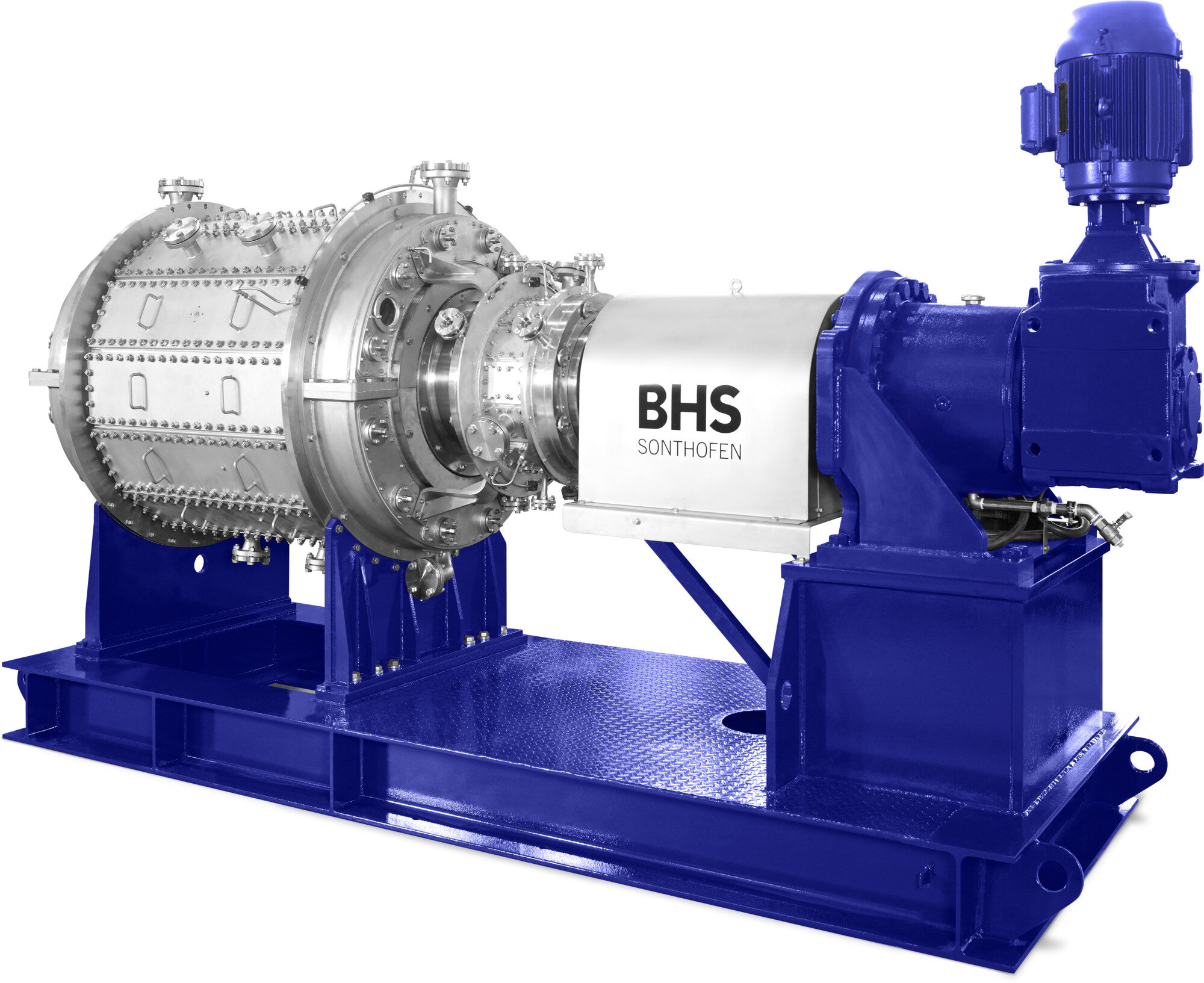

BHS-Sonthofen Group

BHS-Sonthofen is an owner-operated group of companies specialized in machinery and plant engineering. The Group is headquartered in Sonthofen, Germany. In keeping with our mission “Transforming Materials into Value,” we offer innovative process solutions, technologies and consultancy services in the Process Technology, Building Material Machinery and Recycling Technology divisions. Having our experts focus on filtration, drying, reacting, mixing, shredding and recycling in the area of mechanical, thermal and chemical process technology is the basis for our success. Our company has a global presence with 600 employees, four production facilities and nine subsidiaries. We realize innovative and efficient solutions for customers in a variety of industry sectors around the world.