Mixing dry building materials

Generating homogeneous mixtures with a gentle touch

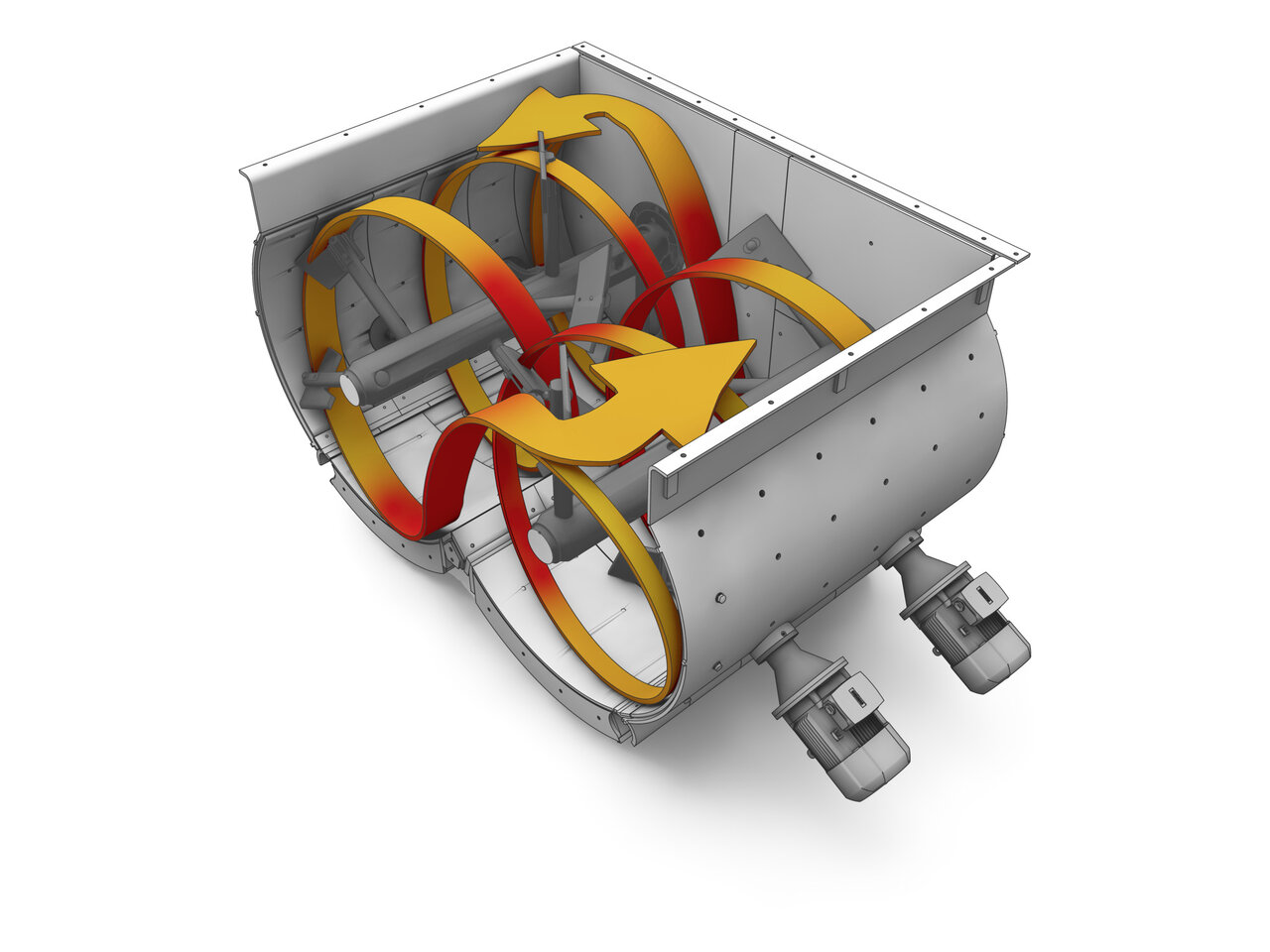

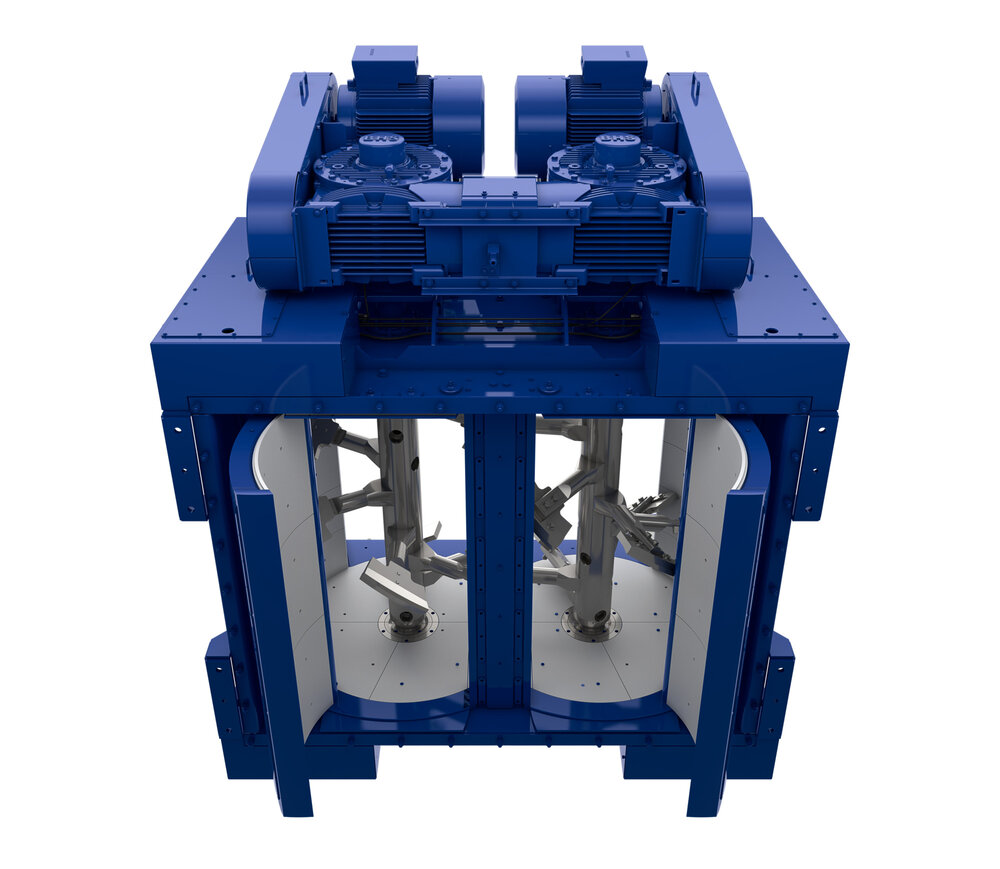

When mixing dry building materials, maximum homogeneity is a key criterion. At the same time, the mixing tools must not damage sensitive particles in the mixture. With the dry powder batch mixer (type DMX), you are on the safe side when processing dry mixtures: The system was specially developed to meet the particular requirements of mixing dry mortar and other dry construction materials. The DMX combines the advantages of the three-dimensional mixing principle with innovative complete material discharge.

Video

The dry powder batch mixer (DMX) for the production of dry material mixtures

The dry powder batch mixer (DMX) for the production of dry material mixtures

Twin-shaft mixing technology is suitable for all formulas and offers a wide range of benefits. The mixing procedure has a significant effect on the quality of the mixture produced and the economic efficiency of the production process. Watch the video to learn more about the use of the dry powder batch mixer (DMX) at the dry-mortar plant of Rethmisch GmbH.

Innovative approach delivers superior results

Innovative approach delivers superior results

DMX is based on the proven principle of twin-shaft mixing technology: Thanks to its excellent mixing properties, it is already being used successfully in a large number of applications in the dry material sector. The sophisticated mixing mechanism with its directional three-dimensional movement is highly effective, delivering improved mixing results at comparably low speeds. Grain structures of sensitive components of the formulation, such as perlites, polystyrene or expanded concrete, are completely retained due to the lower rotational speed.

Innovative mixing concept features clever details

Innovative mixing concept features clever details

Two large, tightly sealing discharge flaps enable optimum complete discharge to facilitate frequent product changes. The “Monogate” version with rotary gate discharge can be used for the consistent production of mass products. The smooth mixing mechanism reduces material build-up to a minimum. Depending on the application, linings in different materials, special plastic blades, various monitoring systems and a wide range of accessories are available.

Production of sand for dry mortar

The “sand maker”

We offer the ideal crushing technology to obtain the sand required for dry mortar production. The rotor impact mill (type RPM) is perfectly suited for producing high-quality, cubical crushed sand. The produced grading curve remains constant over the entire service life of the tools. Even off-spec grain sizes < 4 millimeters or return material are processed efficiently.