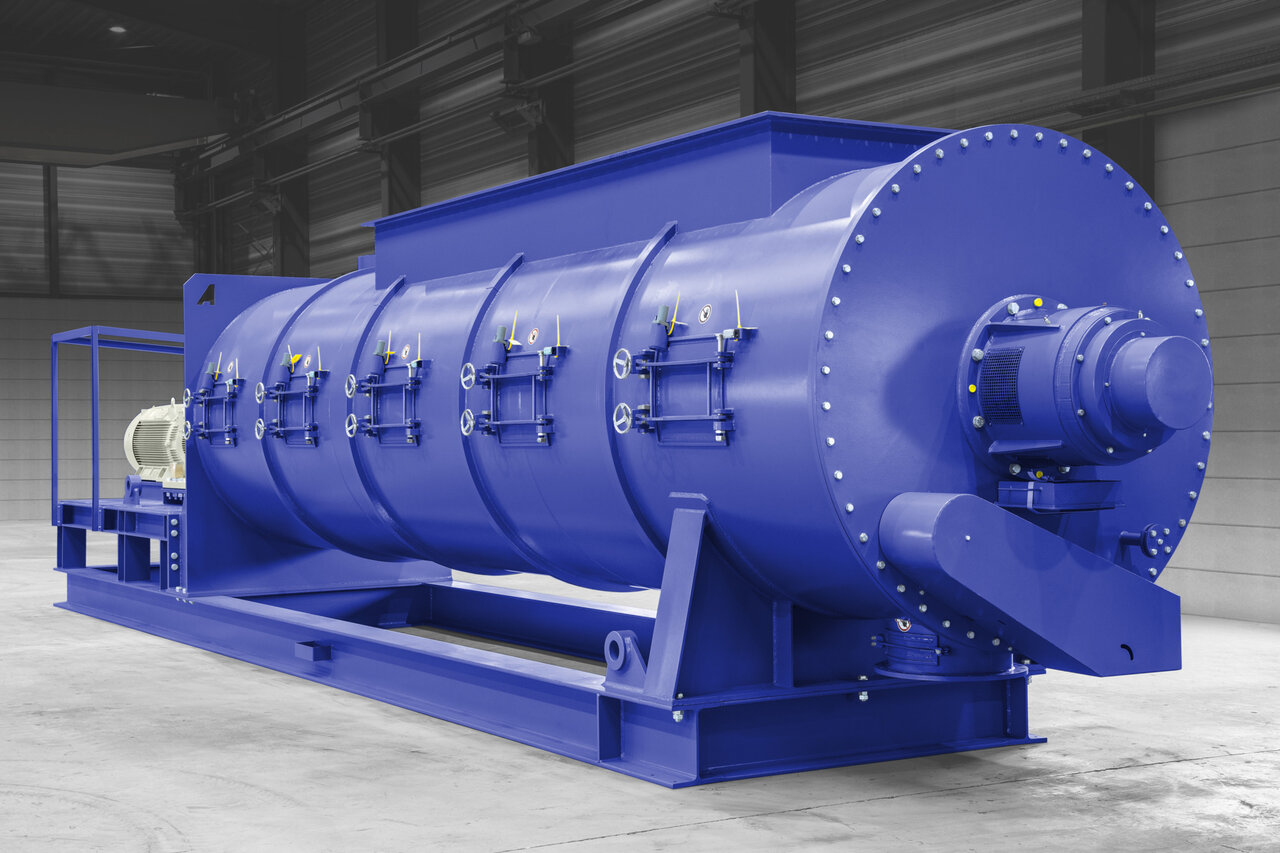

Horizontal mixer

Optimal mixing quality with short mixing times

BHS horizontal mixers achieve excellent results for gentle homogenization and preparation of solid mixtures, solid-liquid mixtures, and pasty mixtures. The spectrum ranges from powder mixers to heavy-duty models. Even the smallest quantities can be fed into the mixer by manual addition. Highly abrasive products are countered with special carbide overlay welds.

Variable processes with frequent product changes

Variable processes with frequent product changes

BHS batch mixers are optimally suited for variable processes and frequent product changes. These horizontal mixers induce mechanical turbulence or, alternatively, process aggregate mixtures. The task of the mixer is to deliver a homogeneous mixture featuring an extremely small variation coefficient within a batch time (loading/mixing/discharge) of between two and five minutes. Decades of experience and a wide range of equipment delivered in various installation sizes, materials, and styles, speak for themselves. BHS batch mixers are available in various designs, depending on your requirements.

Continuous processes with large throughput volumes

Continuous processes with large throughput volumes

BHS continuous mixers are excellently suited to large throughput volumes in continuous processes. These horizontal mixers induce mechanical turbulence or alternatively process aggregate mixtures. Our robust technology allows for 24-hour continuous operation, 365 days a year. The raw materials are fed continuously via appropriate dosing units and nozzles, and the finished mixture is continuously discharged via suitably designed discharge elements. Thanks to special agitators, BHS continuous mixers achieve very high throughput rates and optimal backmixing despite compact installation sizes.

Technical specifications

Operating criteria

Operating method | batch or continuous |

|---|---|

Operating pressure | Atmospheric |

Operating temperature | -40 °C to 650 °C |

Machine size / | 0,1 - 80 m3 0,1 – 2.000 m3/h |

All data given corresponds to the standard version. Technical data for customized versions may deviate from the specified data. All technical data is subject to development. Subject to change at any time.