Dry powder batch mixer

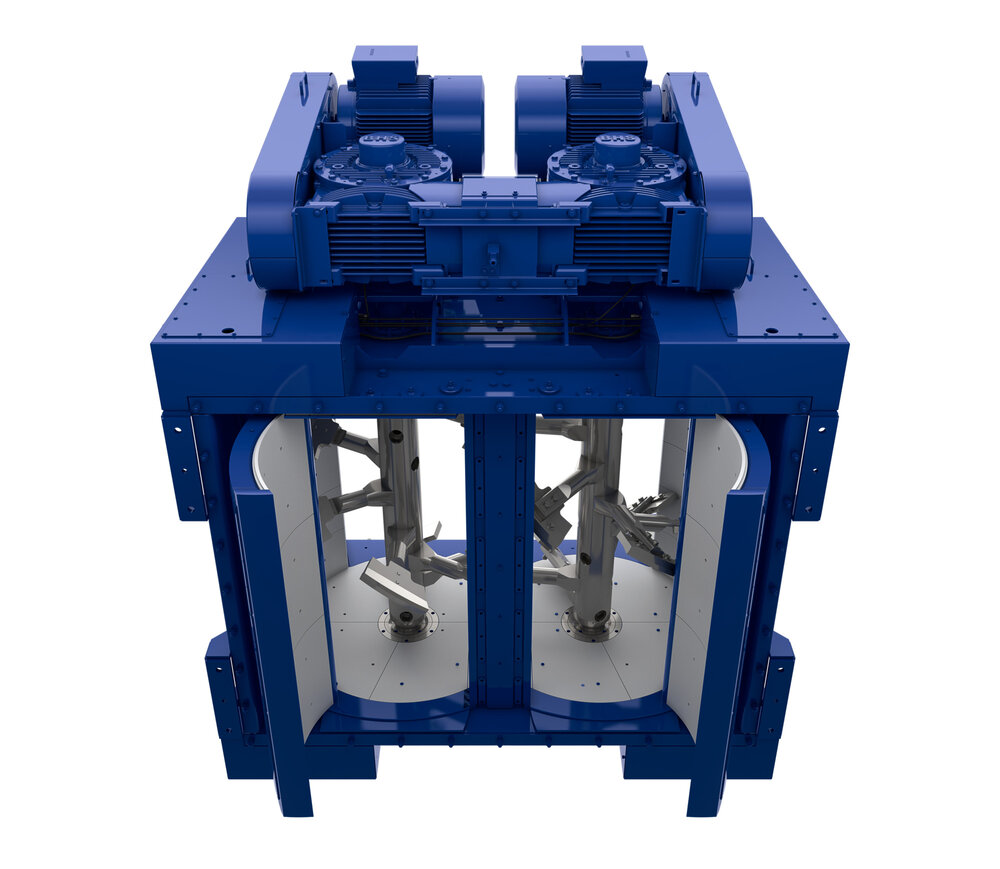

The dry powder batch mixer (DMX) for the production of dry material mixtures

The dry powder batch mixer (DMX) for the production of dry material mixtures

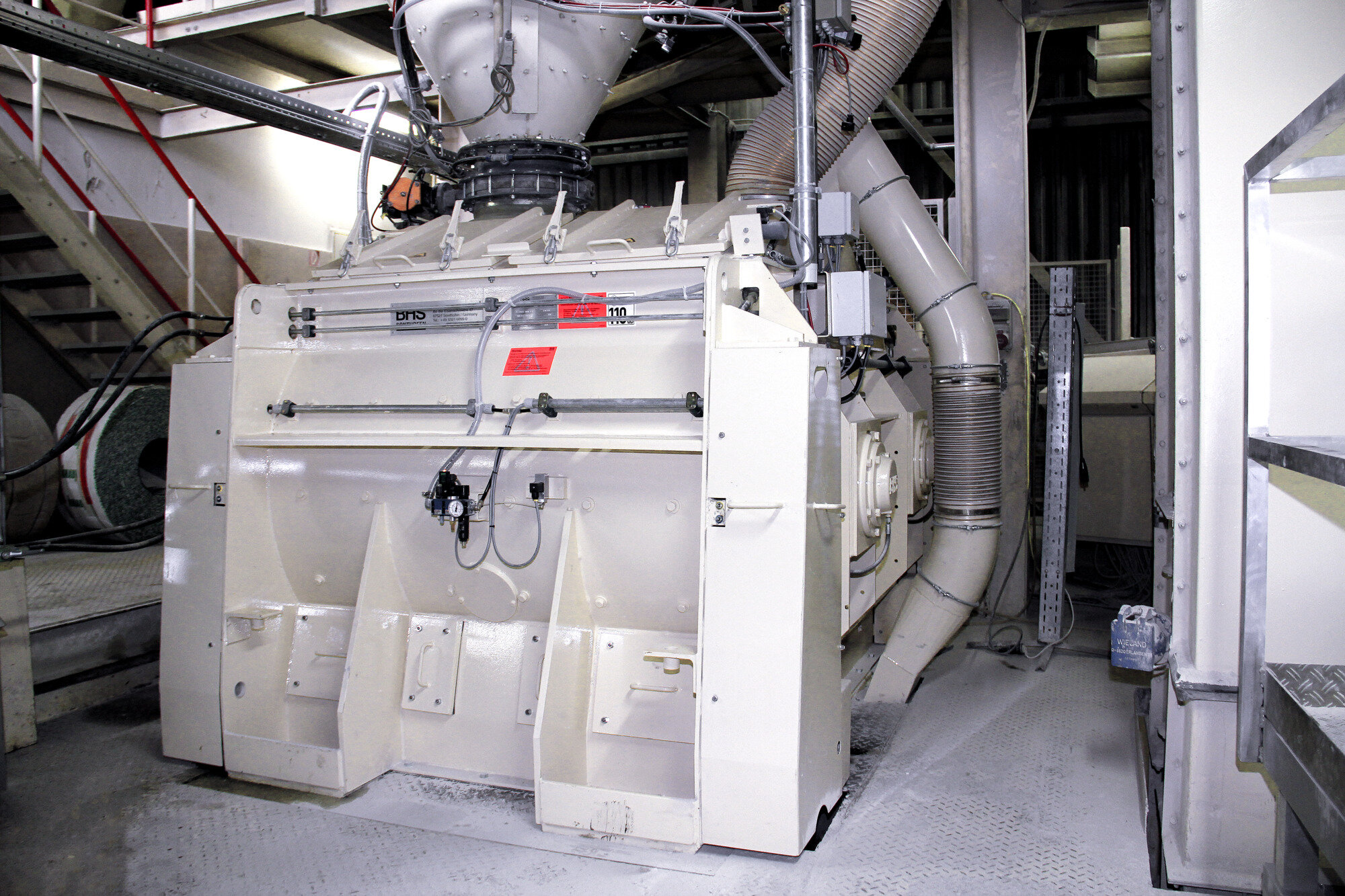

Twin-shaft mixing technology is suitable for all formulas and offers a wide range of benefits. The mixing procedure has a significant effect on the quality of the mixture produced and the economic efficiency of the production process. Watch the video to learn more about the use of the dry powder batch mixer (DMX) at the dry-mortar plant of Rethmisch GmbH.

Highlights

Consistent and reliable mixing results

- Sophisticated design and arrangement of the mixing tools

- Achieves a consistently high mixture homogeneity despite short mixing cycles

Gentle processing of the mixture

- Special spiral blade mixing unit and careful material transport ensure gentle processing of sensitive components in the mixture (e.g. perlite, polystyrene or expanded clay)

- Preservation of the grain structure of the formulation’s individual components

Compact design

- Can be filled to a considerably higher level in comparison with other mixer systems, thus enabling the same throughput in a more compact design

- Small dimensions facilitate use in new plants

- A more powerful mixer can be installed in the existing space

Maintenance-friendly and robust design

- Sturdy and durable design

- Compact design that provides easy access for maintenance work

Residue-free DMX emptying

- Residue-free mixer emptying by means of two large dust-tight and torsion-resistant discharge flaps

Low-residue DMX Monogate emptying

- Low-residue emptying by means of massive, dust-tight rotary valves

Low wear

- Minimized ratio of wearing surfaces to batch volume due to compact design and high filling level

Technical systems

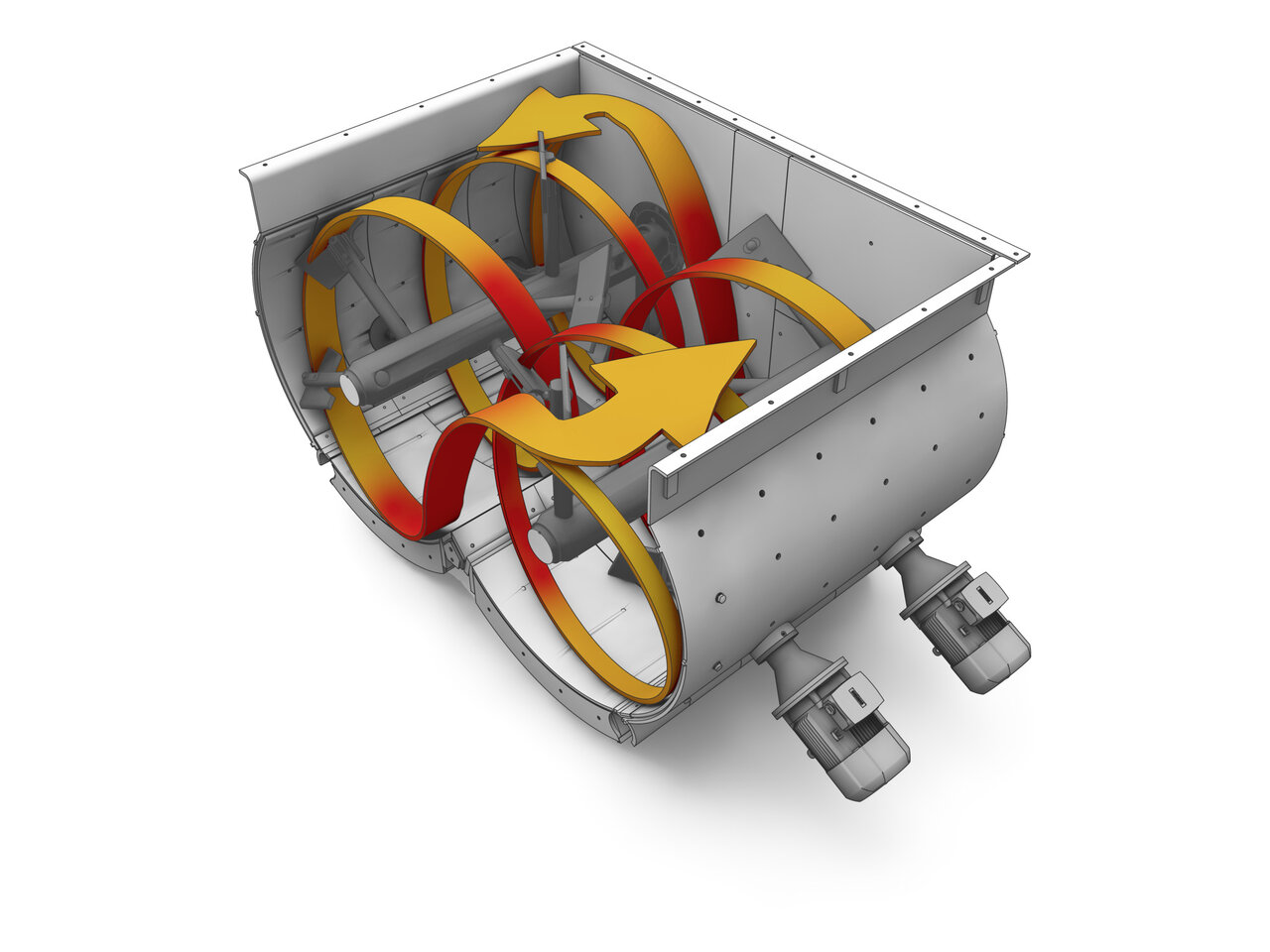

Advantages of the Three-Dimensional Mixing Concept

Unlike single-shaft systems, which move the mixture to the center of the machine, the three-dimensional mixing concept of the twin-shaft batch mixer produces a more intensive exchange of materials, leading to short mixing times while consuming less energy.

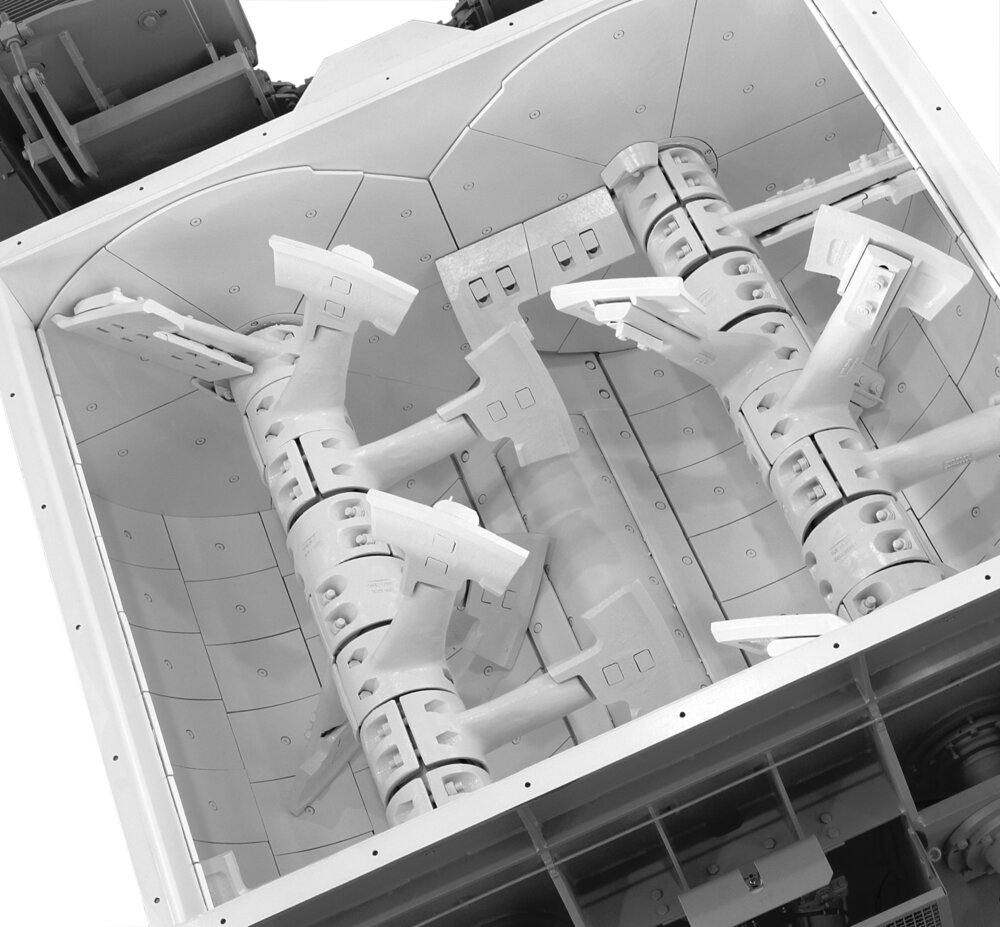

Spiral mixing tools

Spiral mixing tools

- Mixing tools arranged on each mixing shaft in the shape of an interrupted spiral

- Two counter-rotating mixing shafts with the mixing tools overlapping in the longitudinal center of the mixer

- Counter blades positioned at the ends of the shafts

- Moderate circumferential speed of the mixing blades for gentle processing

Mixing principle

Mixing principle

- Generation of a circular three-dimensional movement pattern of the entire mixture

- Intensive material exchange in the turbulent overlap zone of the two mixing circuits

- Optimal conversion of the energy input into intensive relative movements of the mixture

- Total volume of material is always included in the mixing process

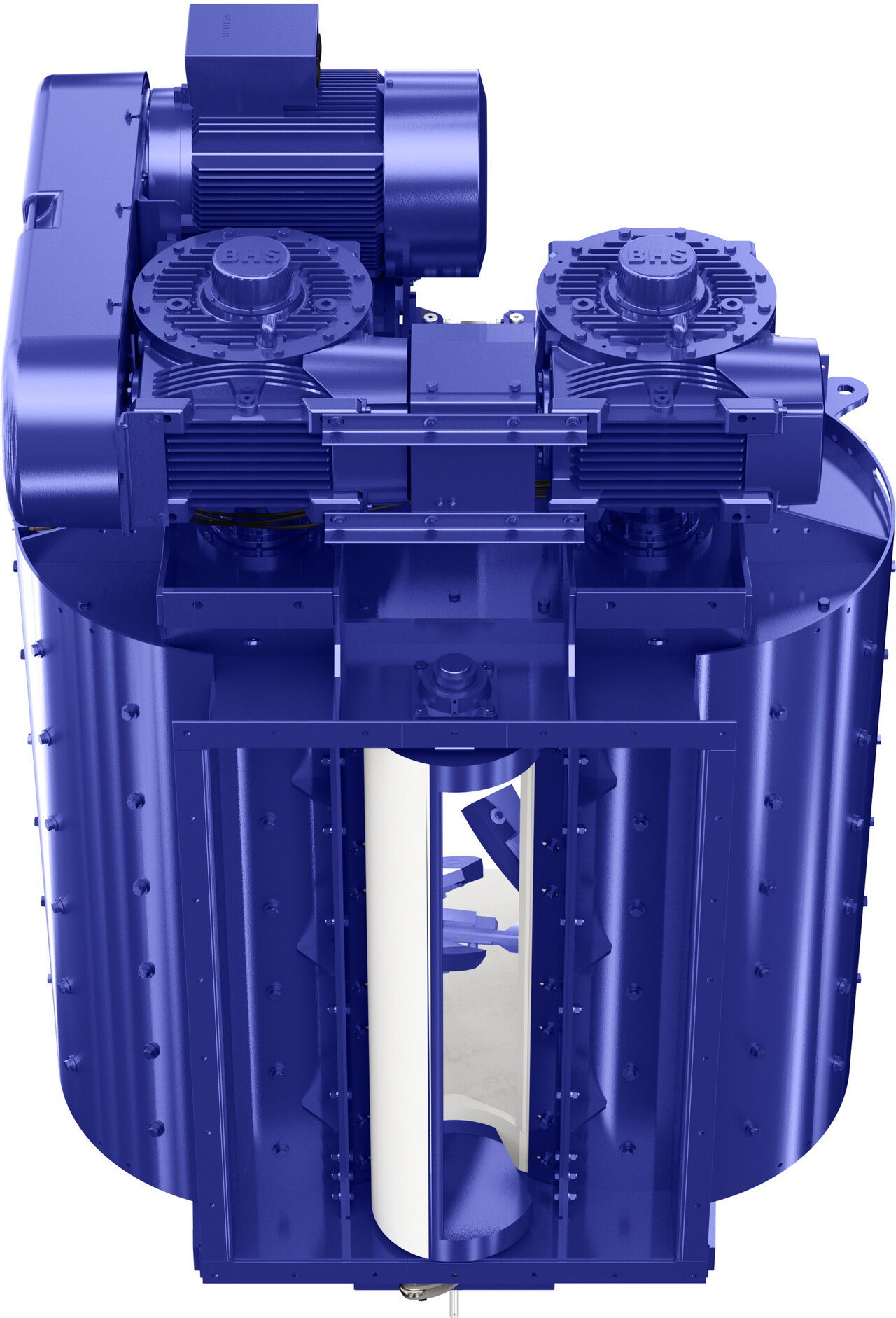

Sophisticated and proven drive technology

Sophisticated and proven drive technology

Gearbox [1]

BHS worm gears boast maximum operational reliability and a long service life, even under extreme loads. The gearboxes are attached to the mixing shafts without rigid connection to the mixing trough. The selected material pairing allows the BHS worm gearbox to compensate the load changes that occur each time the mixer is filled.

Electric motor [2]

All of our twin-shaft batch mixers are equipped with high-quality motors. They are specifically designed for the load cycles generated.

V-belt drive [3]

The power is transferred via V-belt drives. Positioning the V-belt drives on the outside of the drive provides good accessibility when performing maintenance work.

Torque support [4]

The adjustable torque support is used for the alignment of the gearboxes. It also allows the gearbox to be fastened to the mixing trough without pressure, avoiding unnecessary loads on the gearbox toothing. This special feature is an essential prerequisite for achieving a long gearbox life.

Synchronous coupling [5]

A low-maintenance elastic coupling is installed between the gearboxes to synchronize the two mixer shafts.

Shaft seal & bearing

The mixer shafts are reliably sealed with axial face seals. The shaft bearings are mounted on bearing lanterns and are physically separated from the shaft seals. This significantly increases the operational reliability of the mixer shaft bearings.

Fluid coupling (optional)

The hydrodynamic fluid coupling prevents both mechanical and electrical load peaks. Its use is recommended in particular if unstable electricity supply conditions prevail on site. Alternatively, the mixer can be operated via a frequency converter or soft-start devices.

Mixer configuration

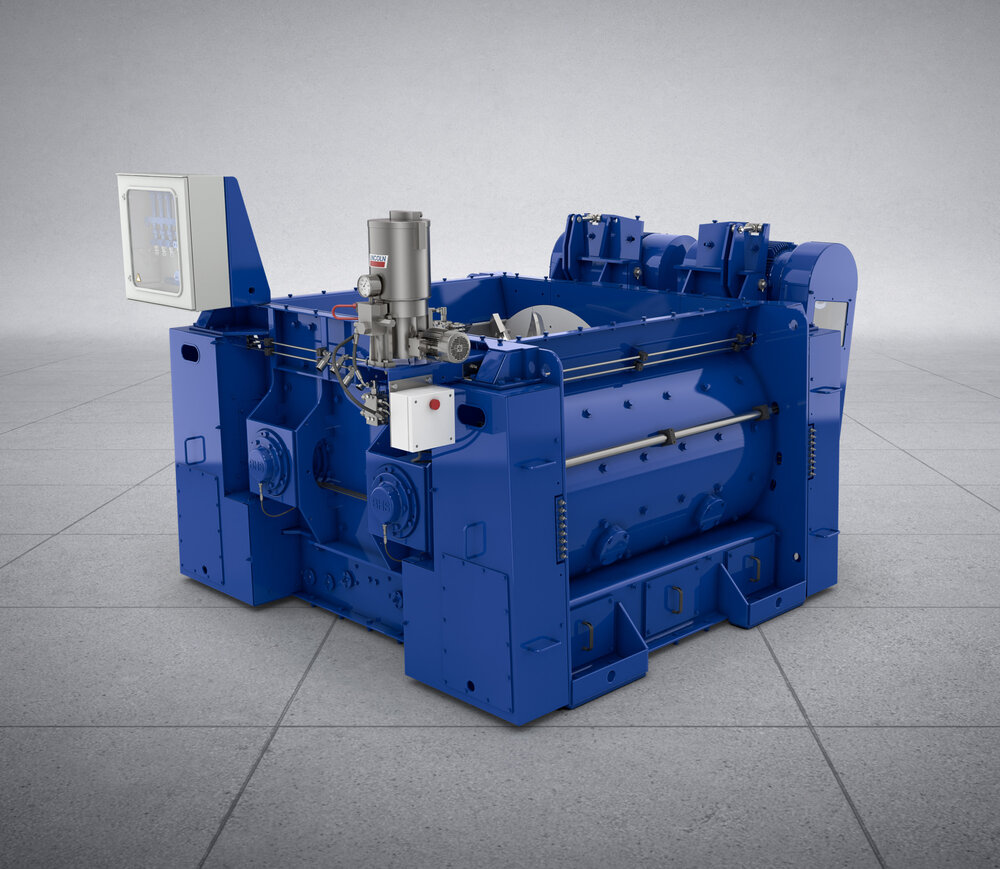

Design features of DMX discharge door flaps

- Residue-free discharge through large dual door flaps

- Discharge door flaps cover the entire length and width of the trough

- Solid and machined welded construction

- Reliable and readjustable door seals, 100 mm high

- Deflector design all around, spring loaded on the lateral side

- Hydraulic operation

DMX Monogate discharge gate design features

- Rotary gate arranged over the entire length of the trough

- Solid and machined design

- Reliable and readjustable seals

- Pneumatically or hydraulically operated

We have years of experience and comprehensive expertise when it comes to retrofitting existing mixing plants. The dry powder batch mixer is ideal when retrofitting in tight spaces thanks, to its compact design. As an added benefit, the use of a high-performance dry powder batch mixer can significantly increase the throughput rate of the plant. Installing a mixer with a higher performance and bigger capacity as well as adjusting the weighing system, dosing and control system can make the plant substantially more competitive.

Options & accessories

The mixer can be equipped with agitators along the longitudinal side of the trough for the purpose of disintegration undesired agglomerations. They are very efficient due to the high filling level of the mixer, as they are in constant contact with the circulating mixture.

Technical specifications

Performance data

| Type | Effective volume | Throughput rate | Drive | Processed particle size | ||

|---|---|---|---|---|---|---|

| 90-second cycle time | 150-second cycle time | From | to | |||

DMX 1200/ DMX 1200 MG | 1.050 l | 42 m³/h | 25m³/h | 1 x 15 kW | 1 x 37 kW | 0 mm - 8 mm |

DMX 1600 | 1.400 l | 56 m³/h | 34 m³/h | 1 x 15 kW | 1 x 37 kW | 0 mm - 8 mm |

DMX 1700 MG | 1.500 l | 60 m³/h | 36 m³/h | 1 x 22 kW | 1 x 55 kW | 0 mm - 12 mm |

DMX 2200 MG | 2.000 l | 80 m³/h | 48 m³/h | 1 x 22 kW | 1 x 55 kW | 0 mm - 12 mm |

DMX 2600/ DMX 2600 MG | 2.300 l | 92 m³/h | 55 m³/h | 1 x 30 kW | 2 x 37 kW | 0 mm - 12 mm |

DMX 3600/ DMX 3600 MG | 3.200 l | 128 m³/h | 77 m³/h | 1 x 37 kW | 2 x 65 kW | 0 mm - 16 mm |

DMX 4900/ DMX 4900 MG | 4.400 l | 176m³/h | 106 m³/h | 1 x 65 kW | 2 x 75 kW | 0 mm - 16 mm |

DMX 5500/ DMX 5500 MG | 4.950 l | 198 m³/h | 119 m³/h | 1 x 75 kW | 2 x 80 kW | 0 mm - 16 mm |

DMX 6500/ DMX 6500 MG | 5.900 l | 236 m³/h | 142 m³/h | 2 x 37 kW | 2 x 90 kW | 0 mm - 16 mm |

DMX 7300/ 1) DMX 7300 MG 1) | 6.600 l | 264 m³/h | 158 m³/h | 2 x 45 kW | 4 x75 kW | 0 mm - 16 mm |

1) Without hydraulic aggregate on the mixer (placed separately). Agitators drive power: 5.5 kW per unit (maximum six units depending on machine size).

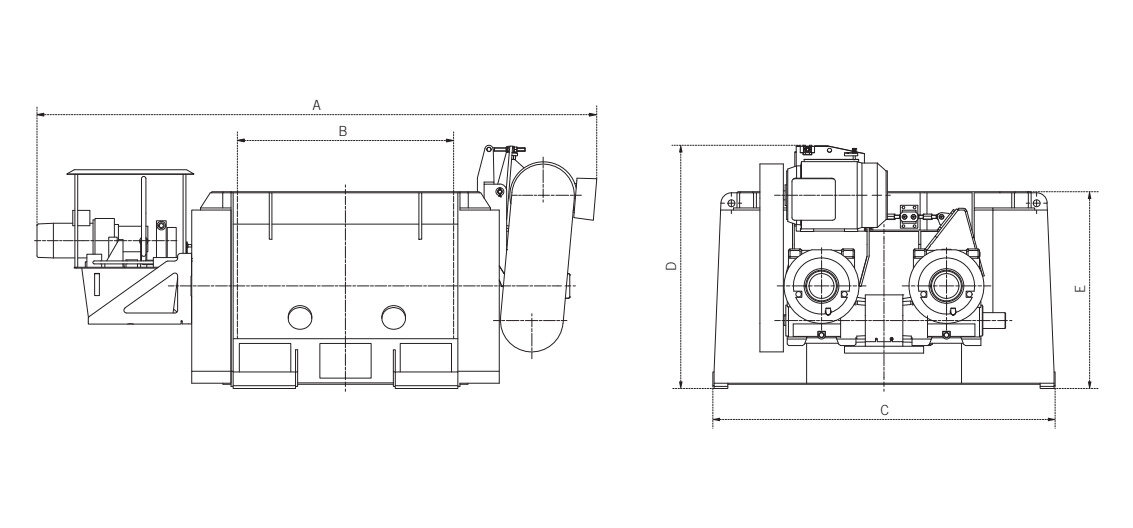

DMX dimensions and weights

DMX

| Type | A | B | C | D | E | weight |

|---|---|---|---|---|---|---|

DMX 1200 | 2.500 mm 2) | 1.330mm | 2.060 mm | 1.400 mm | 1.130 mm | 5.000 kg |

DMX 1600 | 2.900 mm | 1.730 mm | 2.060 mm | 1.400 mm | 1.130 mm | 5.300 kg |

DMX 2600 | 4.010 mm | 1.565 mm | 2.470 mm | 1.830 mm | 1.420 mm | 8.600 kg |

DMX 3600 | 4.070 mm | 1.530 mm | 3.000 mm | 1.990 mm | 1.580mm | 11.700 kg |

DMX 4900 | 4.900 mm | 2.290 mm | 3.000 mm | 2.120 mm | 1.580mm | 15.000 kg |

DMX 5500 | 4.900 mm | 2.290 mm | 3.000 mm | 2.150 mm | 1.850 mm | 15.500 kg |

DMX 6500 | 4.850 mm | 2.310 mm | 3.340 mm | 2.200 mm | 1.850 mm | 18.000 kg |

DMX 7300 1) | 4.850 mm | 2.310 mm | 3.340 mm | 2.280 mm | 1.850 mm | 18.500 kg |

1) Without hydraulic aggregate on the mixer (placed separately). Agitators drive power: 5.5 kW per unit (maximum six units depending on machine size).

2) Dimensions and weights deviate for 4X drive.

Performance data for other materials available on request. All specifications apply to the standard design. Technical specifications for customized designs may differ from the data provided here. All technical specifications are subject to change due to continuous development. Subject to change without notice.

DMX Monogate dimensions and weights

DMX Monogate

| Type | A | B | C | D | E | F | weight |

|---|---|---|---|---|---|---|---|

DMX 1200 MG | 2.670 mm 3) | 1.330 mm | 1.550 mm | 1.470 mm | 1.000 mm | 1.200 mm | 3.500 kg |

DMX 1700 MG | 3.000 mm | 1.330 mm | 2.040 mm | 1.855 mm | 1.200 mm | 1.400 mm | 5.600 kg |

DMX 2200 MG | 3.000 mm | 1.330 mm | 2.040 mm | 1.900 mm | 1.200 mm | 1.400 mm | 5.750 kg |

DMX 2600 MG | 3.250 mm | 1.565 mm | 2.040 mm | 1.940 mm | 1.200 mm | 1.400 mm | 6.200 kg |

DMX 3600 MG | 3.260 mm | 1.530 mm | 2.470 mm | 2.040 mm | 1.400 mm | 1.640 mm | 8.800 kg |

DMX 4900 MG | 4.180 mm | 2.290 mm | 2.470 mm | 2.080 mm | 1.400 mm | 1.640 mm | 11.400 kg |

DMX 5500 MG | 4.180 mm | 2.290 mm | 2.470 mm | 2.110 mm | 1.400 mm | 1.640 mm | 11.700 kg |

DMX 6500 MG | 4.670 mm | 2.310 mm | 2.855 mm | 2.400 mm | 1.650 mm | 1.890 mm | 15.700 kg |

DMX 7300 MG | 4.670 mm | 2.310 mm | 2.855 mm | 2.400 mm | 1.650 mm | 1.890 mm | 16.000 kg |

3) Dimensions and weights deviate for 4X drive.