Twin-shaft continuous mixer

Twin-shaft continuous mixer

The twin-shaft continuous mixer of type LFK is an efficient, reliable solution for continuous mixing processes, especially when handling coarser particles. The mixer is particularly suitable for the production of mineral mixtures, hydraulically-bound base layer concrete, landfill sealings, lean concrete, heavy concrete, dry mixtures etc. BHS also offers complete continuous mixing plants including sophisticated weighing, dosing and control technology as well as individual plant components.

Highlights

Consistently superior mixture quality

- Intensive vertical and horizontal mixing thanks to counter-rotating movements of the two mixing shafts and inclined mixing tools

- Weighing and metering technology ensure consistently superior mixture quality that adheres to the formulation

Material bed offers wear protection

- Natural material bed that forms in the mixing trough during operation

- Mixer with round trough and tiles made of a special chilled cast chrome alloy as a design and equipment option

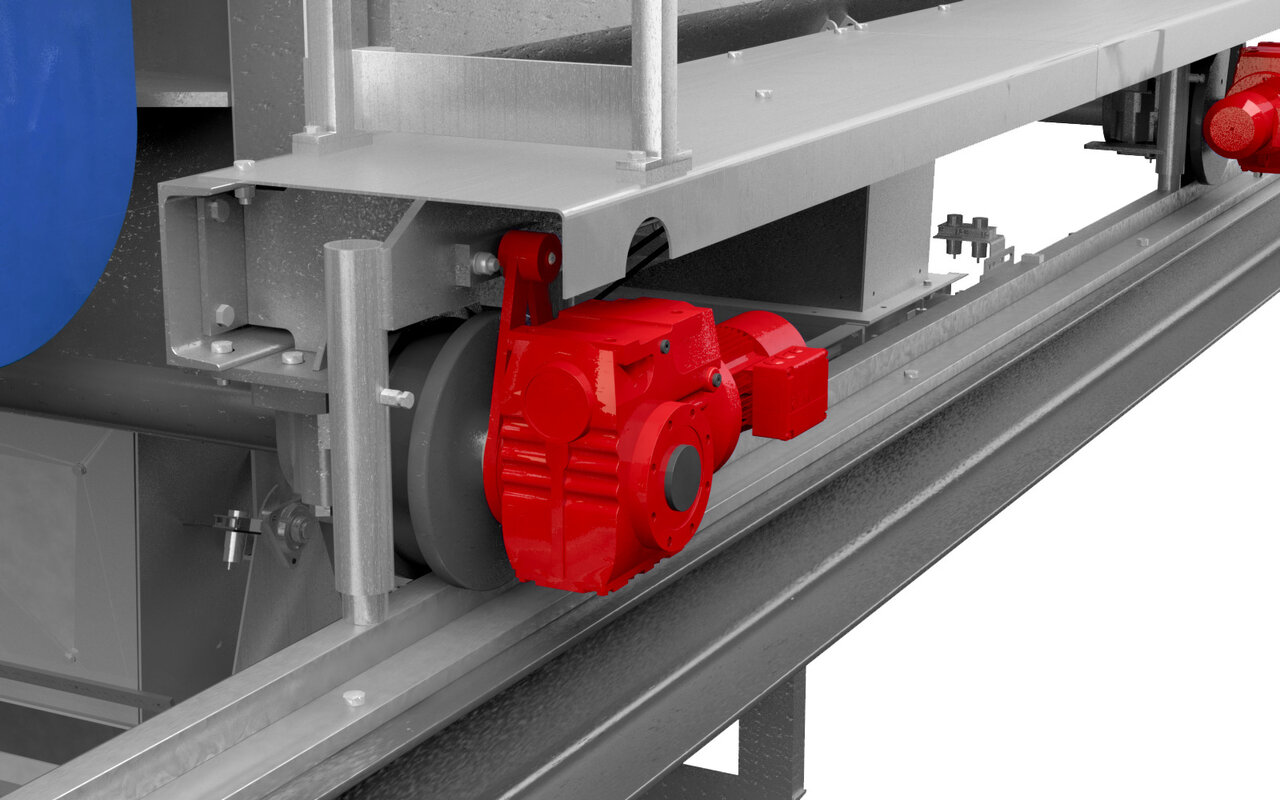

Sophisticated and proven drive technology

- High operational reliability, energy efficiency and long service life are guaranteed thanks to drives installed by BHS

- High efficiency due to worm gear specially designed for the BHS twin-shaft continuous mixer

- Reliable power transmission via V-belt drive

- Free suspension of the drive prevents impact loads within the gearbox thanks to torque supports

Maintenance-friendly and robust design

- Sturdy and durable design that also provides easy access for maintenance work

- Large maintenance flaps at the top and bottom

Secure investment thanks to high operational reliability

- Top operational reliability and thus long-term investment security thanks to robust, durable design

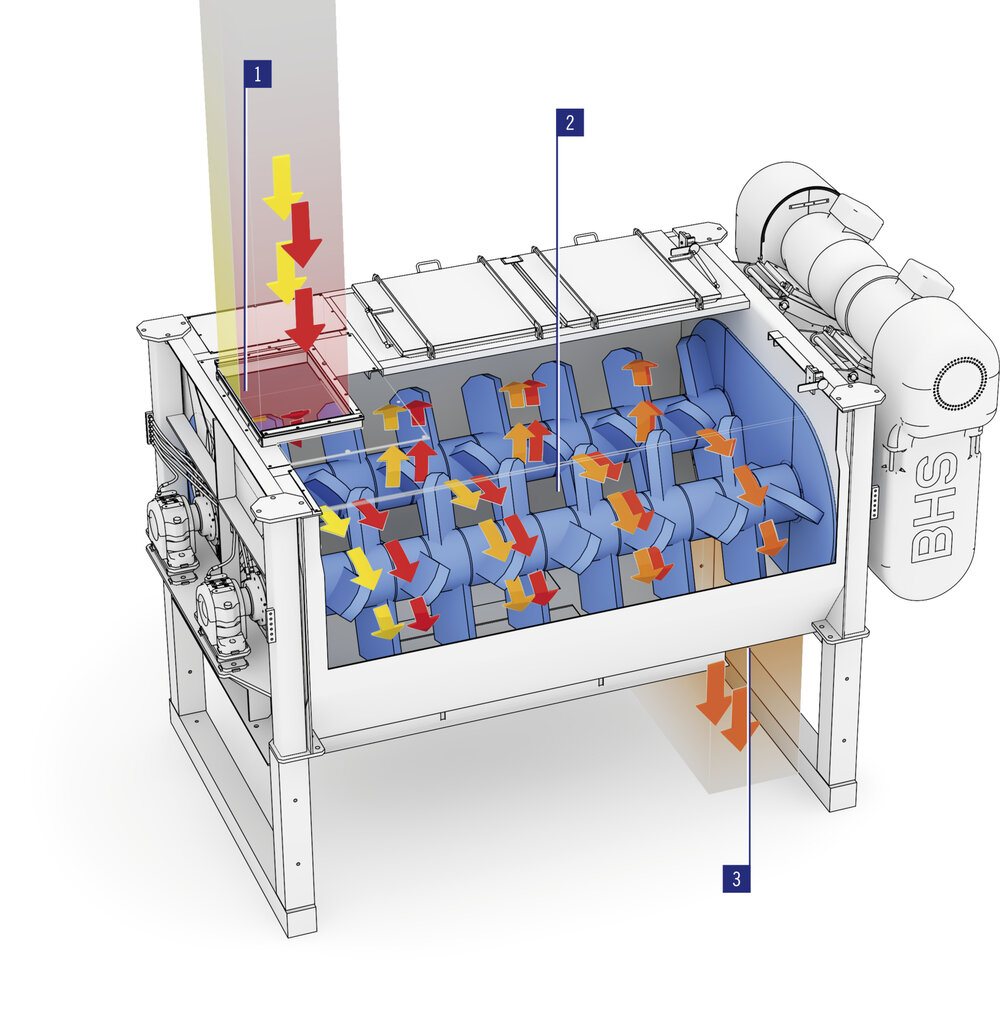

Technical systems

1. Feed area

The mixing tools engage the continuously fed input material and convey it onward. Water is added by means of special nozzles.

2. Mixing section

The counter-rotating movements of the two mixing shafts and the inclined mixing tools ensure intensive vertical and horizontal mixing and continuous transport of the mixture.

3. Discharge area

The mixture leaves the mixer continuously, allowing for transport to downstream systems.

Two versions of the twin-shaft continuous mixer

Two trough designs – square and round – are available to address different requirements of the input material. When mixing coarse materials, a square trough has proven most suitable. The natural material bed offers optimum wear protection. We recommend the round trough design when mixing fine materials.

Comb blades

Comb blades

For mixing cohesive, fine-grained materials, special comb blades are available for the removal of material adhesions on the mixing trough.

Fluid coupling

Fluid coupling

The hydrodynamic fluid coupling prevents both mechanical and electrical load peaks. Its use is recommended in particular if unstable electricity supply conditions prevail on site.

Central lubrication

Central lubrication

A central lubrication system continuously supplies the internal mixing trough seals with grease during mixing operation. Different designs are available depending on the desired degree of automation.

Mixers on carriage frames

Mixers on carriage frames

For use in loading stations of quarries, the mixer can be installed on a mobile platform to enable product changes between single grain and grain mixtures.

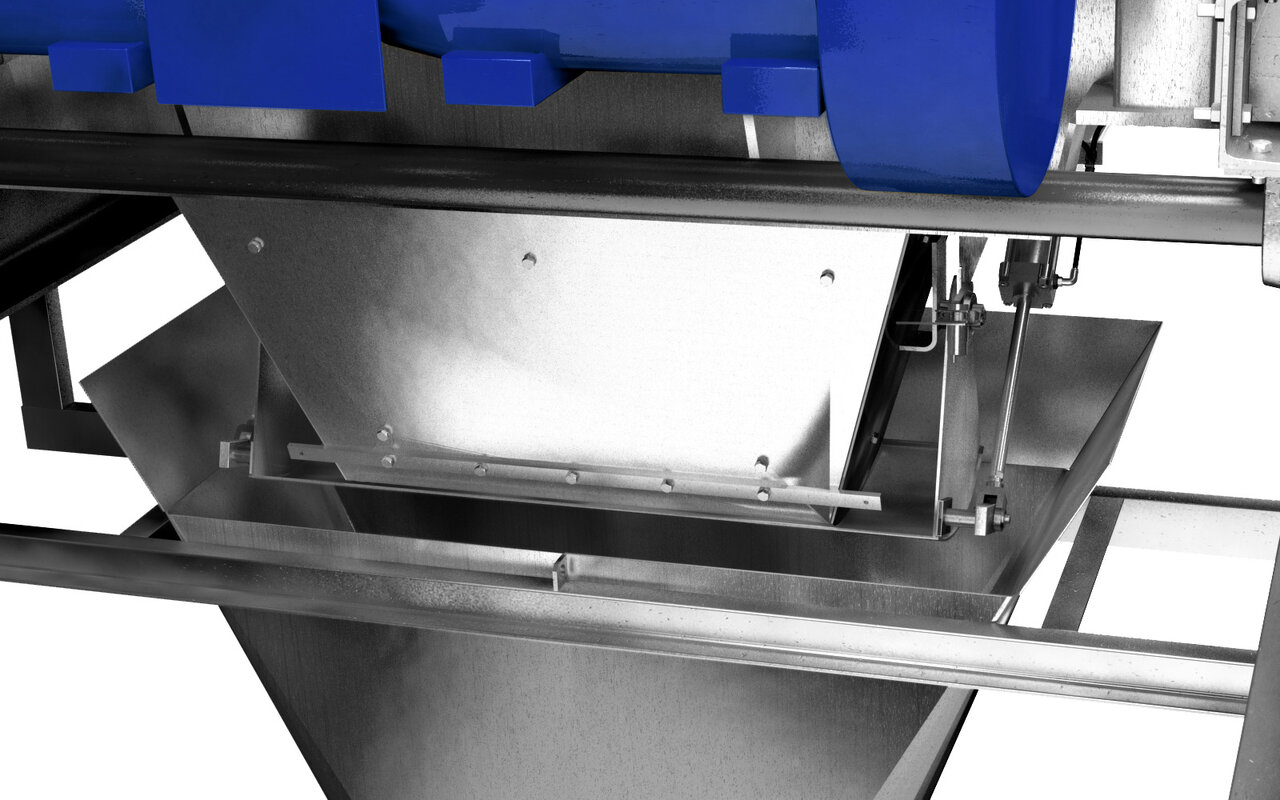

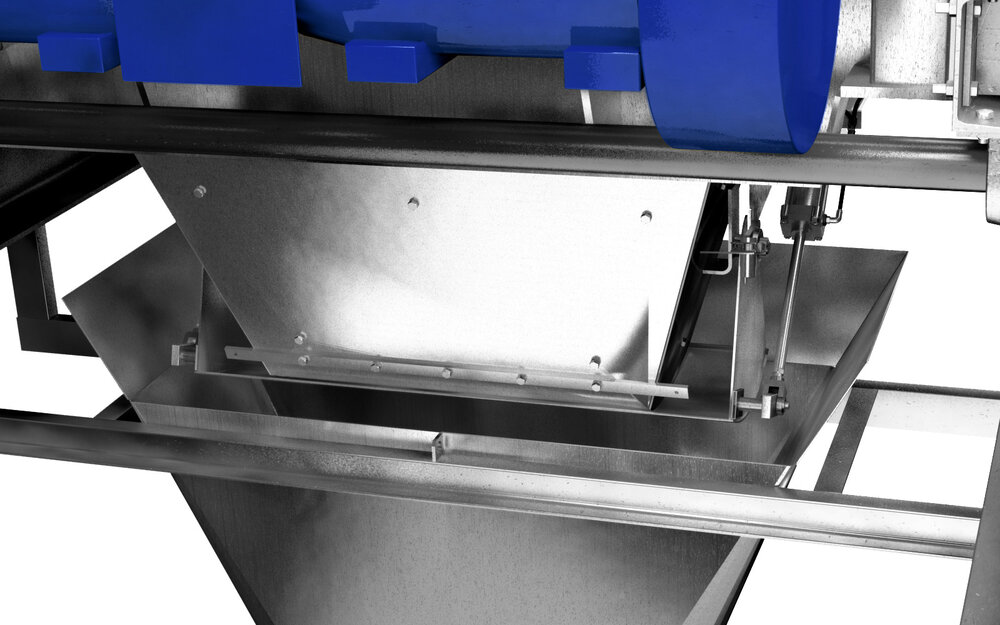

Discharge hopper with segment gate

Discharge hopper with segment gate

A discharge hopper with segment closure and integrated drip protection is available for loading onto open trucks. For loading onto truck mixers, we recommend a discharge hopper with an auxiliary swivel-capable hopper.

Hopper for single grain loading

Hopper for single grain loading

The hopper mounted on the mixer allows for the direct loading of grain mixtures onto open trucks or truck mixers, bypassing the mixer.

Configuration with round mixer trough

Configuration with round mixer trough

The BHS twin-shaft continuous mixer fitted with a round mixing trough is recommended for applications where low-residue discharge is essential. The trough is lined with tiles made of a special chilled cast chrome alloy.

Sealing-air seal

Sealing-air seal

A special sealing-air seal is available for mixing dry materials that must not be contaminated with lubricants.

Application Scenarios

| Areas of use | Applications |

|---|---|

Lean concrete / RCC | Road construction, hydro dam concrete, blinding concrete |

Mineral mixtures | Road construction, path construction, ground stabilization |

Fine-particle and dry mixtures | Dry mortar, cement blendings, fly ash, foundry sand |

Environment and waste disposal | Landfill sealing, backfill, pumpable mixtures, mine filling |

Heavy concrete | Tube coating |

Soils | Gardening soil, soil improvers |

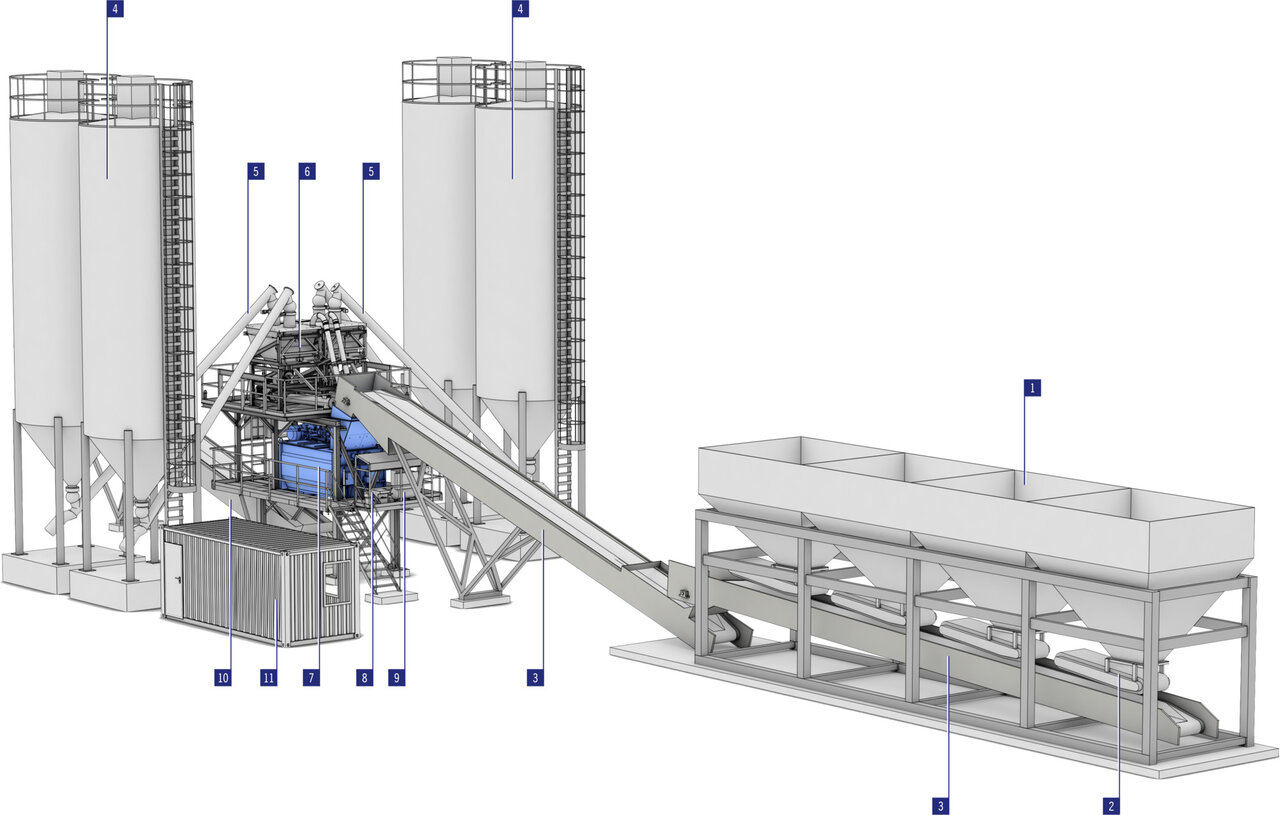

Plant engineering

Continuous mixing plants

BHS offers complete continuous mixing plants of various sizes based on the twin-shaft continuous mixer. The mixing and weighing platforms are designed for easy and cost-efficient transport to the installation site in an ISO container. The batcher and the control technology allow operators to continuously weigh and adjust the formulation’s components with great precision. Continuous mixing plants address the needs of construction sites where large volumes of building materials (e.g., RCC) is required at consistently high quality.

Storage of aggregates [1]

The aggregates are stored in a multi-chamber metering system

Metering band weigher [2]

Speed-controlled metering belts with integrated belt weighers weigh the aggregates continuously and in precise accordance with the formulation.

Collecting belt and ascending belt [3]

The aggregates are metered in layers onto the collecting belt and fed to the twin-shaft continuous mixer via the ascending belt.

Storage of binders [4]

The binding agents are stored in silos. There, the fill level is measured continuously, and air loosening systems and control devices consistently monitor the filling process.

Conveying of binders [5]

The binders are fed to the weighing and metering station via tubular screw conveyors. The screw conveyors are equipped with outlet flaps.

Scale platform with binder metering station [6]

The self-calibrating twin weighing system facilitates exceptionally high metering accuracy. It consists of a hopper scale with a speed-controlled rotary valve as the discharge unit and a screw scale for continuous data measurement value acquisition.

Mixer platform [7]

In the BHS twin-shaft continuous mixer, which is mounted on a generously dimensioned mixer platform, the various materials are mixed thoroughly.

Metering of additives and water [8]

Additives are metered via speed-controlled gear pumps. The water is metered via a control valve. Quantities are recorded via an inductive flow meter.

Compressed air generation [9]

A compressor station supplies the entire mixing plant with compressed air.

Discharge belt [10]

A discharge belt transports the mix directly to the construction site or to the truck loading bay.

Control container [11]

The control station and power control are housed in an air-conditioned 20-foot container.

Technical specifications

Performance data

| Type | Mixing circle diameter | Mixing distance | Mixing throughput 1) | Feed size (max.) | Drive power | ||

|---|---|---|---|---|---|---|---|

| Lean concrete/RCC | Mineral mixes | Fines (dry) 2) | |||||

LFK 0626 | 630 mm | 2.600 mm | 100 - 220 t/h | 100 - 230 t/h | 50 - 130 t/h | 45 | 22 kW |

| LFK 0726 | 750 mm | 2.600 mm | 150 - 325 t/h | 150 - 350 t/h | 70 - 220 t/h | 64 | 37 kW |

| LFK 0926 | 900 mm | 2.600 mm | 200 - 550 t/h | 200 - 700 t/h | 110 - 330 t/h | 64 | 55 kW |

| LFK 1130 | 1.100 mm | 3.000 mm | 350 - 850 t/h | 350 - 1200 t/h | 190 - 550 t/h | 80 | 2 x 37 kW |

1) Throughput capacity for other aggregates available on request.

2) Material density 1.00 t/m³.

Dimensions and weights

| Type | A | B | C | D | E | Weight 3) |

|---|---|---|---|---|---|---|

LFK 0626 | 3.530 mm | 1.250 mm | 1.330 mm | 1.200 mm | 1.330 mm | 3.100 kg |

LFK 0726 | 3.650 mm | 1.440 mm | 1.480 mm | 1.200 mm | 1.500 mm | 5.100 kg |

LFK 0926 | 3.950 mm | 2.000 mm | 1.860 mm | 1.385 mm | 1.850 mm | 6.100 kg |

LFK 1130 | 4.250 mm | 2.370 mm | 2.050 mm | 1.600 mm | 2.260 mm | 9.900 kg |

3) Weight for standard model without accessories.

All technical data shown here refer to the standard version. The technical data for customer-specific versions may vary from the information shown here. All technical data may change due to development. Subject to modification without notice.