Purity and quality

Whether you’re handling amino acids, vitamins or other additives: Dietary supplements are very sensitive. Our filters ensure gentle production as well as top product purity and quality. Economical operation due to high throughput rates is guaranteed.

Amino acids

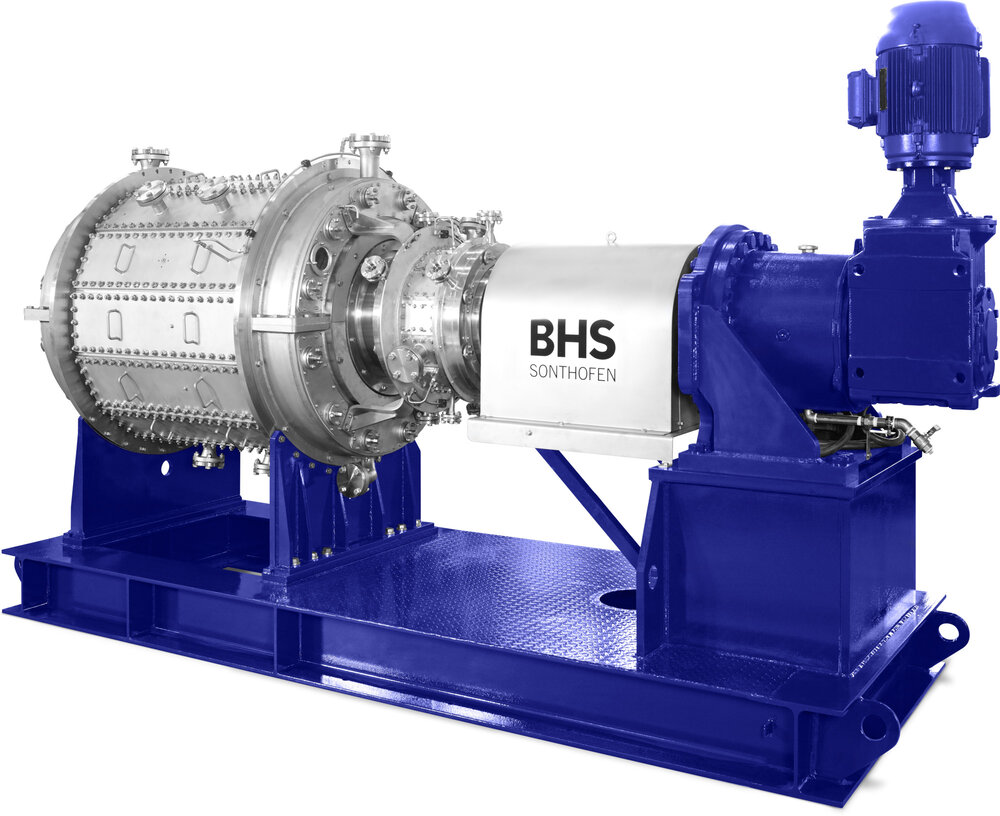

Both the indexing belt filter (BF) and rotary pressure filter (RPF) are suitable for the gentle processing of amino acids. With both machines, you can ensure a uniform, high product quality. After filtration, an efficient washing stage produces high-purity amino acid. Both systems have proven themselves in this application for decades. Our filters are also CIP-compliant for use in the food industry.

Vitamins

High-quality, sensitive vitamins should ideally be processed continuously in a closed system. The rotary pressure filter (RPF) offers the ideal conditions for this. At the same time, it ensures reliable and efficient operation in a process that can be constantly monitored. After separation of the filtrate and filter cake, the product is washed and dehumidified in several stages using a very small amount of detergent. The result is a top-quality solid material free of impurities.