Single-shaft continuous mixer

Single-shaft continuous mixer

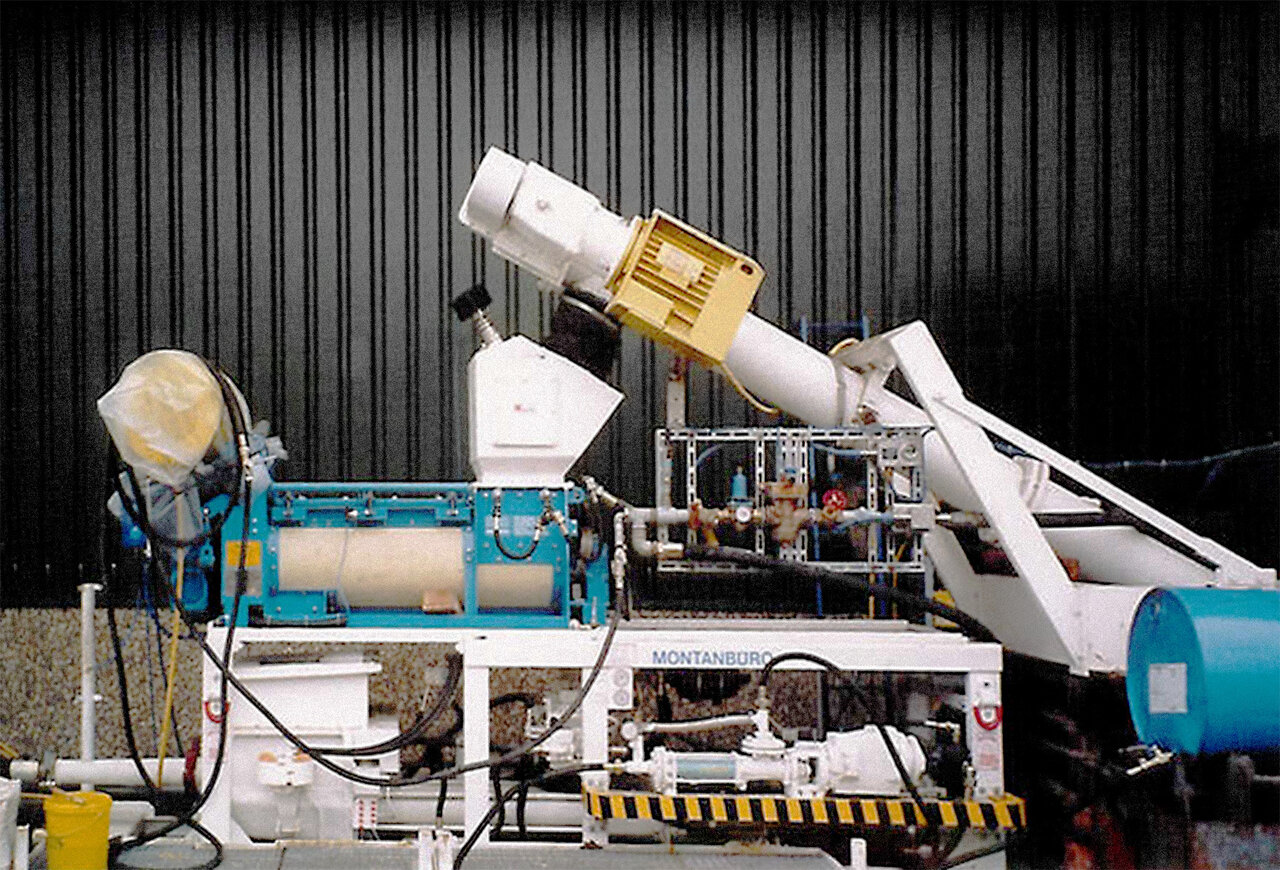

The single-shaft continuous mixer of type MFKG is a continuous mixing system that was developed for the intensive mixing of fine materials. Dry and moist, pasty as well as suspension-like mixtures can be produced continuously with the single-shaft continuous mixer. The special shape and arrangement of the mixing tools ensures an intensive mixing process. What sets the BHS single-shaft continuous mixer apart is the self-cleaning, flexible rubber trough, which prevents build-up on the inner trough wall. Liquids are added through nozzles in the inlet area, which facilitates early and extensive moistening of the entire feed material.

Highlights

Consistently superior mixture quality

The design of the mixer inlet, the shape and arrangement of the mixing tools and the selection of the appropriate speed ensure a consistently high mixture quality. The high speeds cause highly turbulent relative movements in the mixture throughout the entire volume of the mixing trough, thus delivering consistently homogeneous mixing results in a very short time. Moreover, undesirable agglomerations are reliably broken up by shear forces.

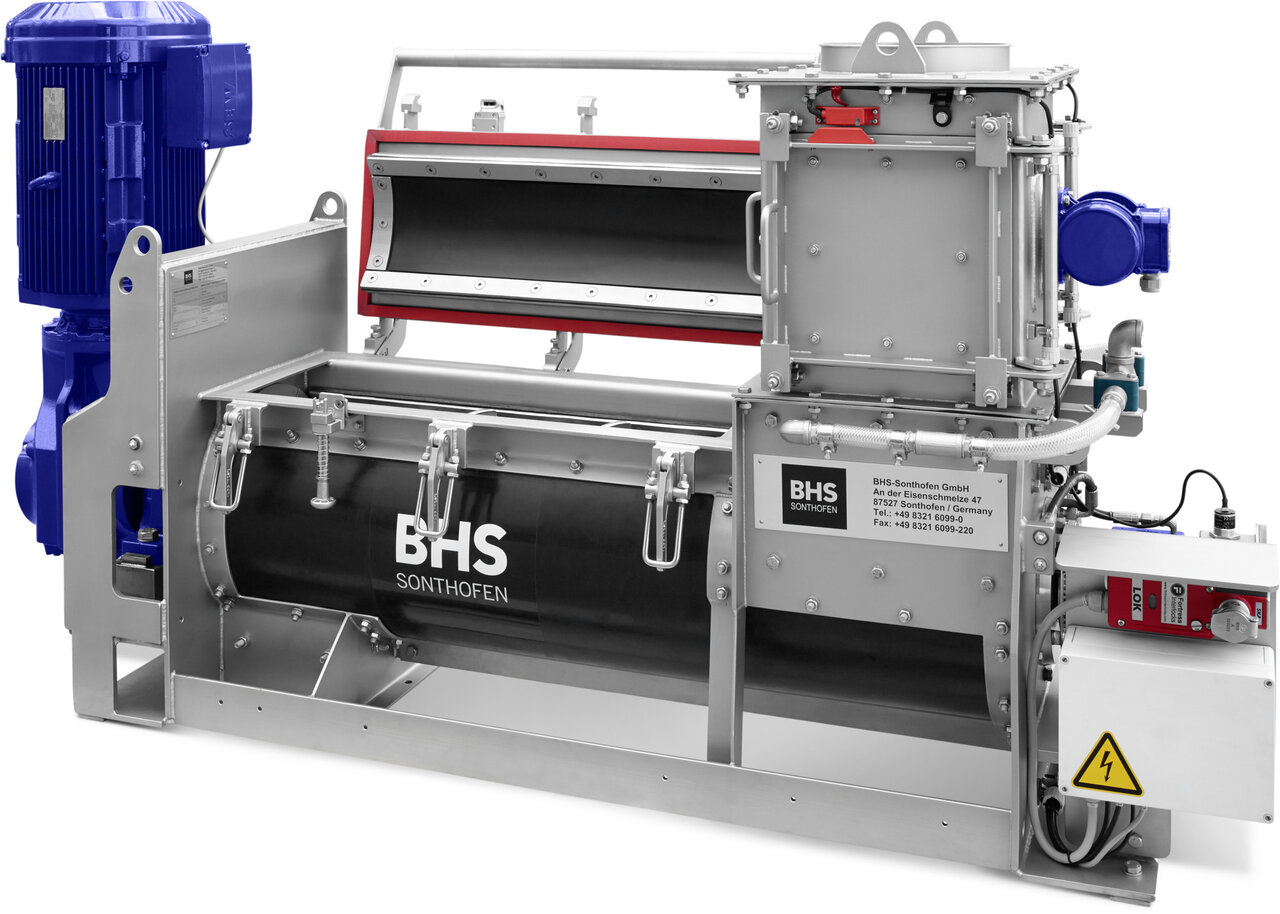

Self-cleaning rubber trough

A unique selling point of the MFKG single-shaft continuous mixer is the self-cleaning process of the rubber trough. The pulsating motion and flexing effects of the rubber jacket prevent hardened mixing material from caking on the trough wall. Owing to this design, the mixer continuously cleans itself during operation.

Large maintenance flap

The rubber trough of the mixer is split in the longitudinal direction over the entire mixing section. This results in a large and easily accessible maintenance opening. Gas springs or hydraulic cylinders assist in operating the maintenance flap.

Secure investment thanks to high operational reliability

Even under the most difficult of conditions, the robust, durable design ensures maximum operational reliability and thus long-term investment security.

Technical systems

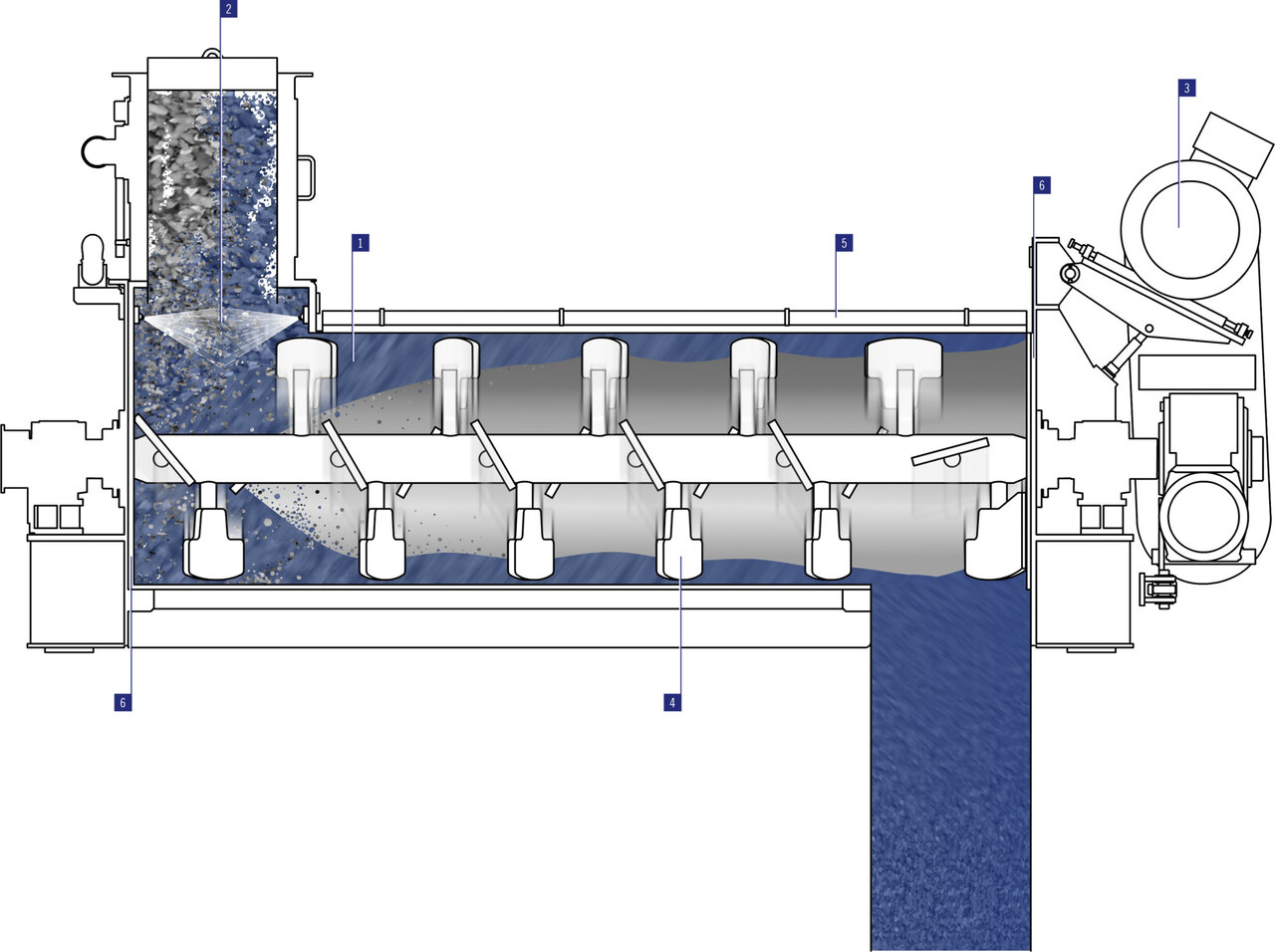

Optimized mixing process [1]

The BHS single-shaft continuous mixer’s rapidly rotating mixing tools greatly accelerate the various components of the formulation. The centrifugal force along the inner wall of the mixer thus creates a ring of mixed material with turbulent zones. The mixing tools generate highly intensive relative movements of the mixed material. This results in an optimal mixing action and a consistently high level of homogeneity. Materials that are generally difficult to mix or that are introduced in vastly different proportions can also be processed.

Inlet chute with efficient liquid injection [2]

In the single-shaft continuous mixer MFKG, liquids that are part of the formulation are only not added in the mixing zone, but also – in contrast to conventional systems – directly in the mixer inlet using special nozzles. This creates a wide spray mist that perfectly moistens all particles of the feed material already during feeding. The mixing tools subsequently ensure an even and intensive mixing of the pre-moistened mixture.

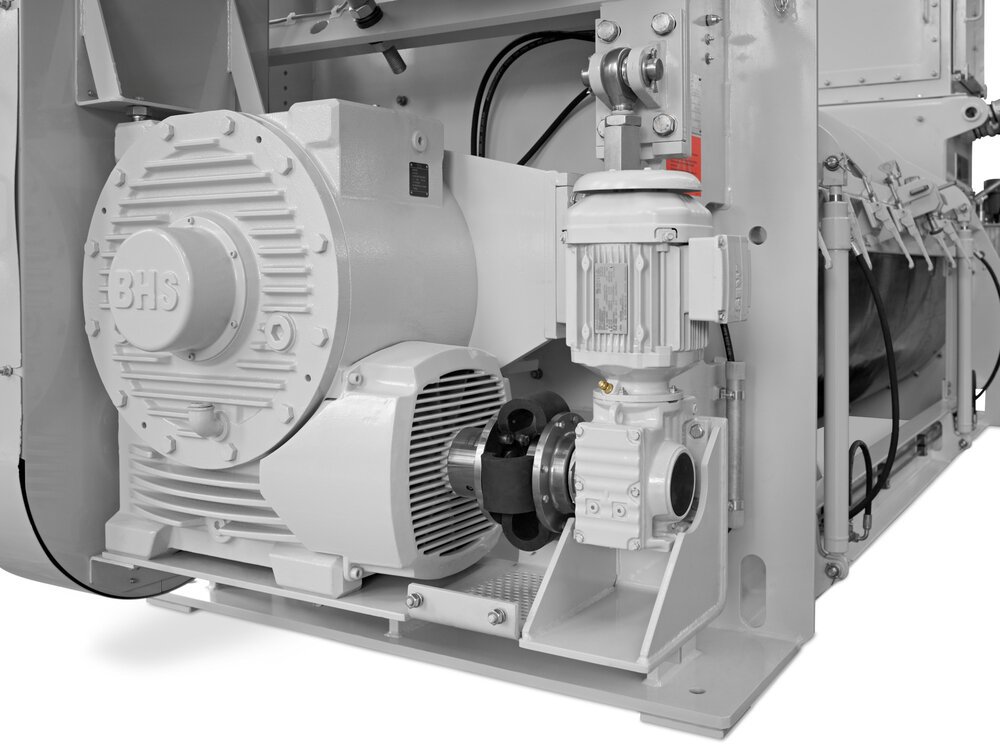

High-performance drive [3]

The drive configuration and performance is parameterized according to the application and the customer’s requirements. The standard drive system comprises a high-performance electric motor, an easily accessible V-belt drive and a robust, highly efficient worm gear. Alternative drive concepts can be implemented to accommodate special requirements.

Customized mixing tools [4]

Depending on the application, the mixer can be equipped with different mixing tools to achieve optimum material acceleration, relative movement and shearing effects. The mixing arms and blades are easily exchangeable. The mixing shaft is smooth to prevent caking.

Large maintenance flap [5]

Thanks to a large maintenance hatch, the mixer is easily accessible across the entire mixing section. Maintenance work can thus be carried out quickly and easily.

Seals [6]

Depending on the task, special axial face seals or gas seals secure the mixing shaft to prevent mixing materials from entering the shaft bearings.

Self-cleaning rubber trough

Self-cleaning rubber trough

The mixing trough of the MFKG single-shaft continuous mixer consists of a flexible rubber jacket tightly fitted into a steel frame. It is made from a highly durable industrial material that is resistant to temperatures of up to 150 °C even in continuous operation. During operation, slight vibrations and flexing effects of the rubber trough prevent caking of hardenable elements of the mixture on the trough wall. This ensures a continuous self-cleaning process during mixer operation. Due to the elasticity of the rubber jacket, the friction loss caused by caking is reduced and, in addition, the wear of the mixing tools is significantly reduced.

Automatic central lubrication

Automatic central lubrication

When the machine is in operation, the central lubrication unit continuously supplies the internal shaft seals with barrier grease, thus reducing maintenance work.

Water control system

Water control system

Depending on the amount of solids added, liquids are introduced via a fully automatic metering station. This consists of a flow meter, control valve, metering valve, pressure regulator and pressure switch.

Hydraulics-driven cover opening

Hydraulics-driven cover opening

A hydraulic actuation mechanism is available to allow for easier and faster opening of the machine cover for maintenance and inspection.

Auxiliary motor for mixer shaft

Auxiliary motor for mixer shaft

An auxiliary motor can be fitted for slow or cycle-based rotation of the mixer shaft. This allows for hassle-free cleaning and maintenance.

ATEX design

The mixer and its peripheral devices can be configured according to the respective ATEX zones. BHS-Sonthofen meets all requirements and is ATEX certified.

Stainless steel design

To cater to special requirements, such as corrosive mixing products, we offer to manufacture the single-shaft continuous mixer from stainless steel.

Fields of application

Continuous dosing and weighing

Technical specifications

Performance data

| Type | Throughput rate 1) | Max. particle size | Max. temp. | Drive power 2) |

|---|---|---|---|---|

MFKG 0313 | 10 - 20 t/h | 12 mm | 150 °C | 9,2 - 22 kW 3) |

MFKG 0520 | 20 - 50 t/h | 16 mm | 150 °C | 37 kW 3) |

MFKG 0728 | 50 - 100 t/h | 16 mm | 150 °C | 45 - 55 kW |

MFKG 1032 | 100 - 300 t/h | 16 mm | 150 °C | 90 - 132 kW |

MFKG 1237 | 300 - 450 t/h | 16 mm | 150 °C | 110 - 160 kW |

1) The bulk density of the specific input materials must be specified for selection of the suitable mixer size.

2) The throughput parameters (max. particle size, bulk density, etc.) of the specific input materials must be specified for selection of the suitable drive power rating.

3) Drive via bevel gear motor.

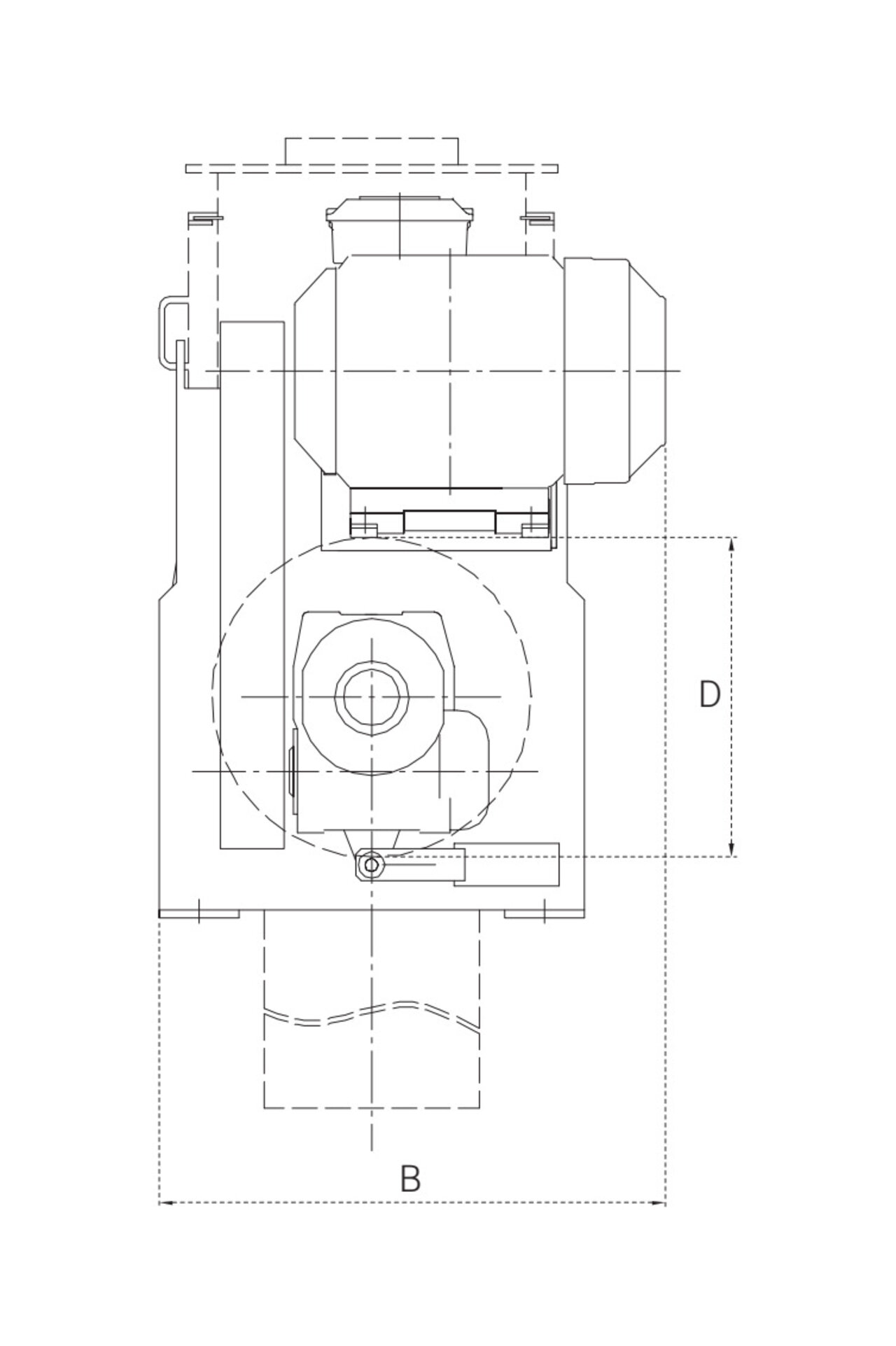

Dimensions and weights

| Type | L1 4) | L2 Rubber trough | D Rubber trough | L3 | H1 | H2 | H3 | B | Weight5) |

|---|---|---|---|---|---|---|---|---|---|

MFKG 0313 | 1.000mm | 1.300 mm | 350 mm | 2.200 mm | 1.200 mm | 620 mm | 1.110 mm | 700 mm | 900 kg |

MFKG 0520 | 1.560 mm | 2.000mm | 530 mm | 3.000 mm | 1.400 mm | 815 mm | 1.420 mm | 900 mm | 2.500 kg |

MFKG 0728 | 2.300 mm | 2.800mm | 750 mm | 3.900 mm | 1.600 mm | 1.150 mm | 1.880 mm | 1.200 mm | 3.700 kg |

MFKG 1032 | 2.550mm | 3.200 mm | 1.000 mm | 4.700 mm | 2.200 mm | 1.400 mm | 2.230 mm | 1.500 mm | 5.800 kg |

MFKG 1237 | 3.000mm | 3.700 mm | 1.250 mm | 5.200 mm | 2.400 mm | 1.700 mm | 2.500 mm | 1.800 mm | 8.500 kg |

4) Dimension from center of mixer inlet to center of mixer outlet.

5) Weight for standard design without accessories.

All specifications apply to the standard design. Technical data for customized designs may differ from the specified data. All technical data may change due to development. Subject to modification without notice.