Indexing belt filter

Indexing belt filter

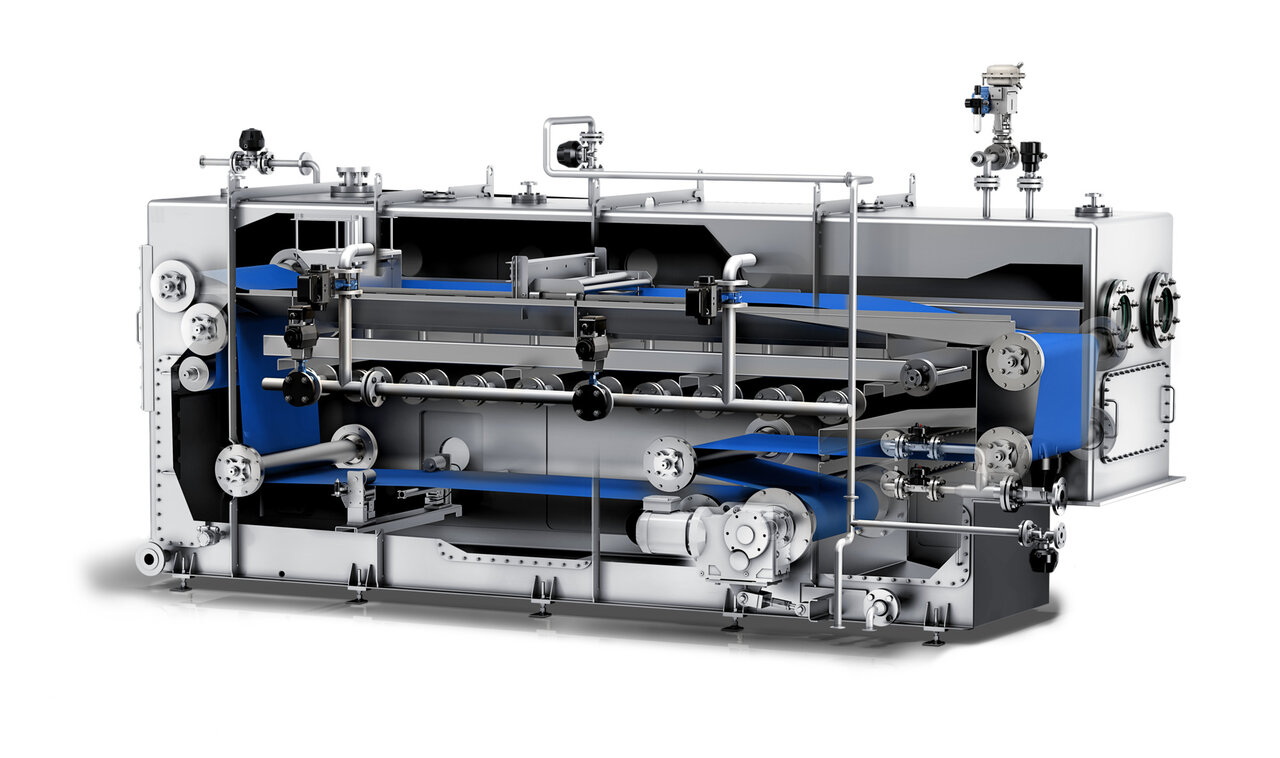

The indexing belt filter of type BF is a continuously operating vacuum filter that can be used to filter solid suspensions gently and reliably. The suspension is fed from above and the filter cake forms on the belt. A vacuum is applied under the belt, which sucks the filtrate through the belt. The cyclical operation of the belt with stationary vacuum trays ensures sharp filtrate separation. The quality of the filter cake is achieved via further process steps such as washing, steaming, drying or pressing.

Highlights

Versatile technology solutions

During the cyclic movement of the belt, the filter supports a multitude of steps for further processing the filter cake: Washing out (if necessary, several times and using a counter-current), slurrying, steaming, extraction, dry suction or pressing. The filtrates can be acquired separately during each cycle and processed in an optimized manner without any intermixing.

Stationary vacuum trays

The vacuum trays and the associated filtrate drains are firmly attached to the filter frame. Wear due to moving parts is not possible. The filter cloth moves forwards in cycles, together with the filter cake. Each time the cloth stops, the filtrate is sucked downwards. The vacuum is then switched off temporarily, and the filter cloth is released for further transport.

Alternative drives

The feed of the indexing belt filter is implemented using a drive roller in connection with a subsequent blocking roller. The feed can be affected via an electric direct drive or by means of pneumatically or hydraulically driven cylinders that generate a lifting movement.

Gentle processing of solids

The design of the BHS indexing belt filter facilitates uniform suspension feeding via optimized distribution devices that gently introduce the solids into the process. The filter cake formed by gravity and a vacuum is not subject to any mechanical forces during transportation or further treatment. This makes the indexing belt filter also suitable for pressure-sensitive solids as these can be processed without grain fracturing.

Open or closed model

We offer the indexing belt filter in various designs. The standard indexing belt filter design has the unit set on a solid steel frame, and the filter is not enclosed at the top. As an additional option, the filter can be equipped with a closed hood. As a further alternative, we offer to manufacture closed box filters, which can also be delivered in pressure and gas-tight design.

Alternative materials

We have extensive experience in the selection of suitable materials for parts that contact the product. If necessary, we use suitable stainless steel grades or plastics and appropriate seals. If required, ground and polished surfaces are also available.

GMP and ATEX

We produce special-purpose indexing belt filters according to GMP principles and equipped with CIP units for applications in the pharmaceutical, food and bioprocess industries. We are also ATEX certified.

Technical systems

[1] Suspension feeding

Depending on the consistency of the suspension, distribution channels with baffle plates, plate distributors or spoon nozzles can be used. Suitable feeding devices are available even for viscous and fast sedimenting products.

[2] Cake washing

Cake washing is usually carried out with full cone nozzles for washing media without solids. Overflow channels or screen bottom distributors are used for multi-stage counter-current washing with washing filtrates.

[3] Vacuum tray

The firmly installed vacuum tray is located under the filter cloth across the entire length from the feeding area to the cake discharge unit. It is divided into several separate zones which correspond to the feed length of the filter belt. The belt rests on exchangeable support grids in the vacuum tray and is transported gently. Below the support grids there are filtrate collection channels in each zone. These are connected to the filtrate collection pipe via the tray outlet.

[4] Cloth tensioning unit

Cloth tensioning is achieved pneumatically or with spring-cage technology and can be adapted to the respective characteristics of the products.

[5] Belt guide

Two opposite pairs of rollers hold the filter belt precisely in its designated path. Should it deviate from this set path, a belt edge sensor issues a signal to release the roll tension on that side. The second pair of rollers still active on the opposite side returns the belt to the desired position. Both pairs of rollers are set at a slight angle to stretch the filter belt across its width and keep it wrinkle free.

[6] Filtrate discharge

Each individual zone of the vacuum tray is separately connected to the filtrate collection pipe. If different filtrates need to be separated with precision, the filtrate collection pipe can be divided into segments much in the same way the process is divided on the vacuum tray. Quickly opening and closing shut-off devices interrupt the vacuum during belt transport and ventilate the filtrate chamber for a short time.

[7] Drive system & motor

The filter has a freely adjustable electric direct drive to accommodate different throughputs and filtrate characteristics. It comprises a reduction gear unit with a directly connected frequency-controlled drive motor. Alternatively, we offer to implement the drive via pneumatic or hydraulic stroke of the drive roller.

[8] Cloth washing

After cake discharge, the filter medium is cleaned in a separate rinsing chamber. Here the cloth is sprayed thoroughly from the cake side, the reverse side or from both sides. If required, it can also be dry vacuum cleaned.

[9] Cake discharge & scraper

During belt feed, the filter cake is deflected via the discharge roller. Due to the small roller radius, is largely discharged autonomously. A rotating scraper removes any cake residues still adhering to the cloth.

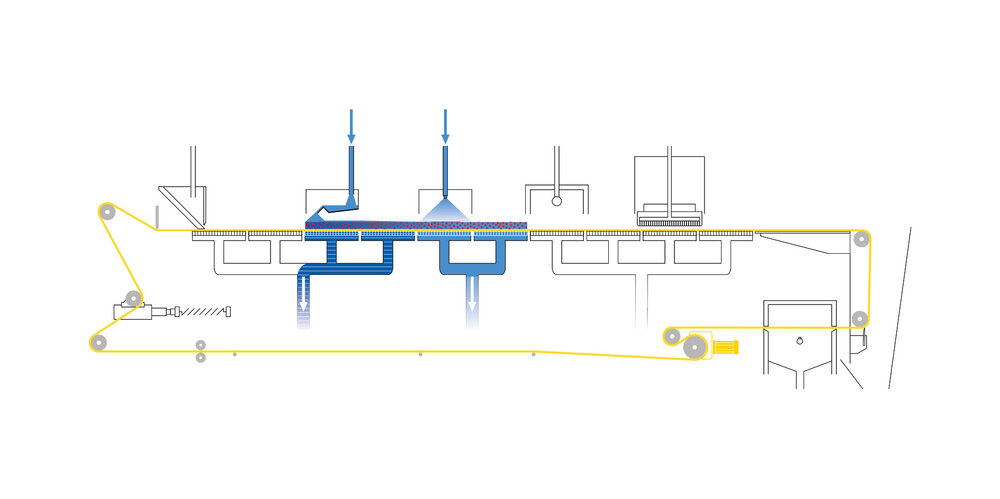

Phase 1: Suspension feed & cake formation

Phase 1: Suspension feed & cake formation

The indexing belt filter offers ideal process engineering conditions for a wide range of separation tasks. One advantage is the controlled suspension feed from above. It ensures that the solid matter is distributed evenly and that it is slightly stratified from coarse to fine, where applicable. The result is optimum permeability. Since filtration occurs in the direction of gravity, the differential pressure of the vacuum system takes full effect. Due to the horizontal position of the cake, no additional forces are required for cake adhesion or filtrate transport. The suspension is filtered down to the desired residual cake moisture.

Phase 2: Washing

Phase 2: Washing

On the indexing belt filters, dissolved contaminants can be washed out from the pore structure of the filter cake by dilution or displacement washing, as appropriate for the relevant requirements. In either case, the filter cake is evenly and completely moistened in the washing zones. Flow-through washing is extremely efficient due to the improvement of the pore structure resulting from the slight compaction of the filter cake during suction on indexing belt filters. The washing liquid, the washing filtrates from counter-current washing, or the different media for extraction or ion-exchange processes are fed to the filter via distribution and feed channels.

Phase 3: Drying

Phase 3: Drying

Various dewatering systems can be used to dry the filter cake downstream of the filtration and washing stages. In addition to pure vacuum dewatering with air, other drying systems are also available. An additional drying effect can be achieved using hot air or steam. The optional pressing unit allows mechanical compaction with or without air-drying stage. It is also possible to combine thermal and mechanical systems.

Phase 4: Cake discharge & cloth cleaning

Phase 4: Cake discharge & cloth cleaning

During the feed process, the filter cake is discharged at the discharge roller. A scraper is installed to support ejection. It removes remaining cake residues from the filter cloth. All indexing belt filters are designed to ensure that the filter cloth is not mechanically damaged by additional removal aids such as scraper blades or removal wires. The filter medium is cleaned in the downstream rinsing chamber. Here the cloth is sprayed with high pressure from the cake side, the reverse side or from both sides. If required, it can also be dry vacuum cleaned. This helps to improve the service life and permeability of the filter cloth and ensures the performance of the indexing belt filter over the long term.

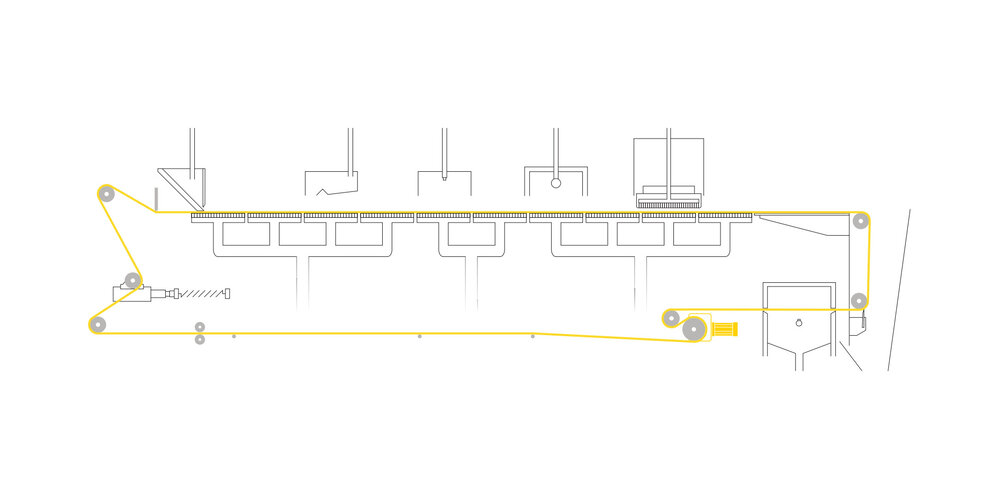

Operating principle of our indexing belt filters

Operating principle of our indexing belt filters

The filter medium is a circulating belt that is moved in cycles. Feeding of the suspension is usually a continuous process. The vacuum trays are rigidly attached to the frame. The filter cloth moves forwards in cycles. Each time the cloth stops, the filtrate is sucked downwards. The vacuum is then switched off temporarily, releasing the filter membrane and allowing it to be transported onwards. A filter cake forms on the conveyor, which can then be flushed out (using a counter-current and possibly several cycles), slurried, steamed, extracted, dried or pressed. The filtrates can be acquired separately from each vacuum tray and processed without any intermixing. The final filter cake is discharged at the discharge roller, and the membrane is cleaned when the conveyor belt is reversed.

Accessories

Designs

Technical specifications

Performance data and dimensions

| Type | Active filter width | Active filter length | Active filter area | Dimensions | ||

|---|---|---|---|---|---|---|

| Length | Width | Height | ||||

| BF 010 | 0,1 m | 1 m | 0,1 m² | 1,7 m | 0,6 m | 0,7 m |

| BF 025 | 0,25 m | 2 - 5 m | 0,5 - 1,25 m² | 4 - 8,3 m | 1,3 m | 1,7 m |

| BF 050 | 0,50 m | 3 - 10 m | 1,5 - 5 m² | 5,4 - 12,4 m | 1,8 m | 1,9 m |

| BF 100 | 1 m | 3 - 12 m | 3 - 12 m² | 5,4 - 14,4 m | 2,3 m | 1,9 m |

| BF 150 | 1,5 m | 3 - 16,5 m | 4,5 - 24,8 m² | 5,4 - 18,9 m | 2,8 m | 1,9 m |

| BF 200 | 2 m | 4 - 18 m | 8 - 36 m² | 6,4 - 20,4 m | 3,3 m | 1,9 m |

| BF 250 | 2,5 m | 6 - 21 m | 15 - 52,5 m² 1 | 10 - 25 m | 4 m | 2,3 m |

| BF 300 | 3 m | 6 - 25,5 m | 18 - 76,5 m² | 10 - 29,5 m | 4,5 m | 2,3 m |

| BF 350 | 3,5 m | 9 - 30 m | 31,5 - 105 m² | 13 - 34 m | 5 m | 2,3 m |

All specifications apply to the standard version.

Technical data for customized designs may differ from the specified data.

All technical data may change due to development.

Subject to modification without notice.

Operating criteria

| Operating method | continuous |

|---|---|

| Operating pressure | vacuum |

| Operating temperature | up to 90 °C |

| Solids content (suspension) | up to 50 % (by weight) |

| Cake thickness | up to 50 mm |

| Grain size | 1 - 100 µm |

| Filter output – suspension | up to 10 m³/m² h |

| Filter output – dry solids | up to 1.000 kg/m² h |

| Active filter surface | 0,1 - 105 m² |