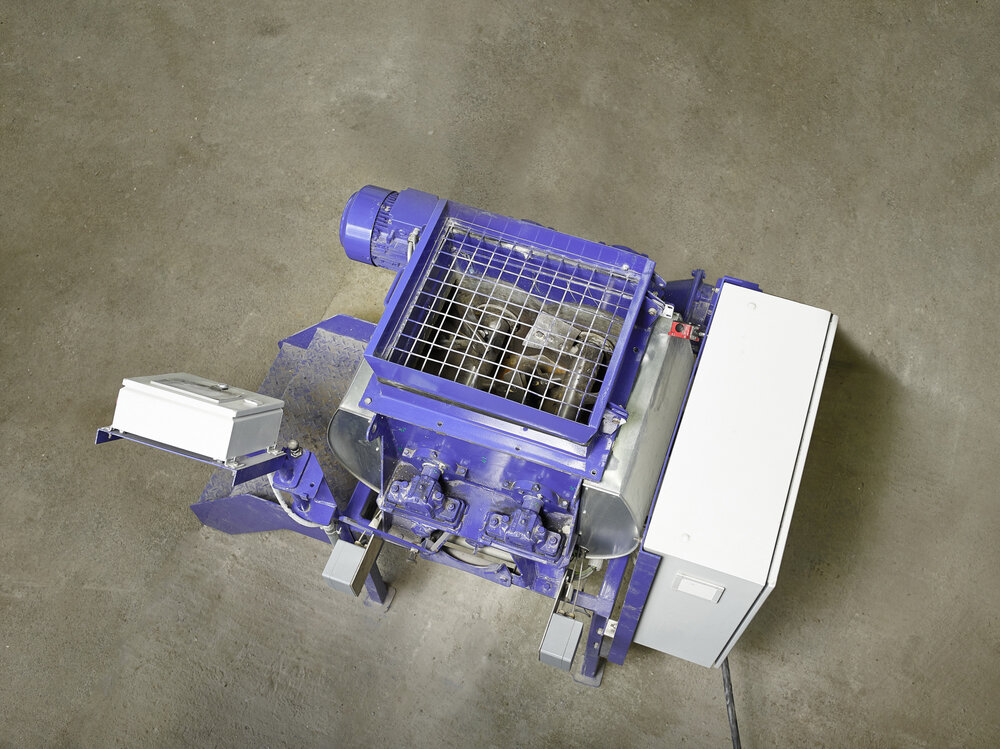

Twin-shaft batch mixer

Twin-shaft batch mixers (DKX) set the benchmark in mixing technology.

Twin-shaft batch mixers (DKX) set the benchmark in mixing technology.

Twin-shaft mixing technology is suitable for all formulas and offers a wide range of benefits. The mixing procedure has a significant effect on the quality of the mixture produced and the economic efficiency of the production process. Watch the video and learn more about major projects from around the world where the twin-shaft batch mixer (DKX) has proven itself under the most difficult conditions.

Highlights

Consistently high mixture homogeneity and short mixing cycles

- Rapid increase in mixture homogeneity through intensive material exchange

- Uniform consistency and homogeneity in every mixing cycle

Optimum energy efficiency

- Excellent mixing performance despite low mixer speed

- Preservation of the grain structure of the formulation’s individual components

- Low specific energy consumption due to short mixing times, optimized mixing mechanism and efficient drive

Design results in low wear

- Low wear on mixing tools and mixing trough lining due to low speeds and compact design

- Significantly less wear and tear than with pan or planetary mixers

- Optimized design of all parts subject to wear

Efficient production of concrete

- Excellent liberation of binders in a short time

- Creates potential for reducing the required amount of binder

- Uniform and fast distribution of additives and admixtures across the entire volume of the mixture

- Possibility of small batches as low as 10% of the nominal filling level

- Safe investment in view of modern concrete formulations

- Supports hybrid mixing cycles (slow – fast – slow)

Comprehensive modular system

Comprehensive modular system

We offer a broad spectrum of mixer sizes and accessories. The extensive modular system allows our twin-shaft batch mixer to be adapted precisely to your needs.

Product range

With our comprehensive range of twin-shaft batch mixers, we offer the right solution for any requirement, thus making our products a safe investment at all times. Depending on the application, you can choose between the following mixers:

- DKX: The powerhouse for top operational safety

- DKXS: The all-rounder

- DKXN: The economical solution for ready-mixed concrete

In addition, we offer mixers with a wide range of configuration options for mixing units, drives, discharge options etc. to address an even grater range of application scenarios.

| Application | DKX | DKXS | DKXN | DKXD | DKXG |

|---|---|---|---|---|---|

Pumped concrete | ✔ | ✔ | ✔ | ||

Ready-mixed concrete | ✔ | ✔ | ✔ | ||

Ready-mixed concrete with input size up to 64 mm | ✔ | ✔ | |||

Shotcrete | ✔ | ✔ | ✔ | ||

Wet mortar | ✔ | ✔ | ✔ | ||

Screed | ✔ | ✔ | |||

Precast concrete | ✔ | ✔ | ✔ | ||

SCC | ✔ | ✔ | ✔ | ||

Specialty concrete grades | ✔ | ✔ | |||

Lean concrete | ✔ | ✔ | |||

Heavy concrete > 2.4 t/m³ | ✔ | ✔ | |||

Coarse-grained mixtures up to 160 mm, depending on machine size | ✔ | ||||

Mixtures for concrete block production | ✔ | ✔ |

BHS Transmission Safety Technology

BHS Transmission Safety Technology

The drive and gearbox unit, which is suspended on an adjustable torque strut, tracks every movement of the mixing shaft. The innovative, high-performance shaft-mounted gear unit absorbs shocks. Along with that, careful material pairing allows the gearbox to compensate for the load changes that occur each time the mixer is filled.

This significantly extends the service life and massively reduces the load on the gearbox.BHS transmission safety technology: Maintain your equipment in its original condition long into the future.

Technical systems

Advantage of the three-dimensional mixing concept

In contrast to the circular motion of other mixing systems, the three-dimensional mixing principle of the twin-shaft batch mixer produces a more intensive exchange of material, which leads to shorter mixing times while consuming less energy.

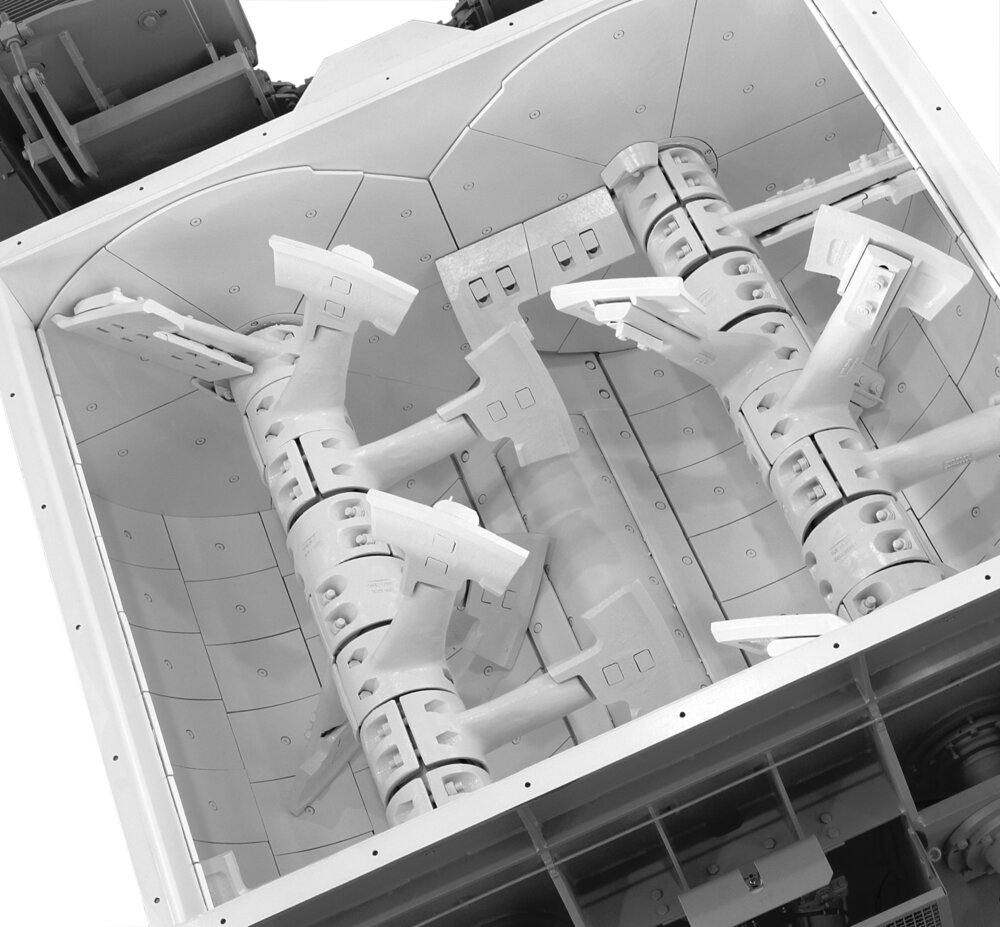

Spiral mixing tools

Spiral mixing tools

- Mixing tools arranged on each mixing shaft in the shape of an interrupted spiral

- Two counter-rotating mixing shafts with the mixing tools overlapping in the longitudinal center of the mixer

- Counter blades positioned at the ends of the shafts

- Moderate circumferential speed of the mixing blades for gentle processing

- High-quality hexagonal shaft with high torsional and bending strength

- Streamlined mixing arms made of special cast steel

- Helical arrangement of the mixing arms as spiral mixer

- Easily adjustable mixer blades

Mixing principle

Mixing principle

- Generation of a circular three-dimensional movement pattern of the entire mixture

- Intensive material exchange in the turbulent overlap zone of the two mixing circuits

- Optimal conversion of the energy input into intensive relative movements of the mixture

- Total volume of material is always included in the mixing process

Gearbox [1]

BHS worm gears boast maximum operational reliability and a long service life, even under extreme loads. The gearboxes are attached to the mixing shafts without rigid connection to the mixing trough. Careful material pairing allows the BHS worm gearbox to compensate for the load changes that occur each time the mixer is filled.

Electric motor [2]

All of our twin-shaft batch mixers are equipped with high-quality motors. They are specifically designed for the load cycles generated.

V-belt drive [3]

The power is transferred via V-belt drives. Positioning the V-belt drives on the outside of the drive provides good accessibility when performing maintenance work.

Torque support [4]

The adjustable torque support is used for the alignment of the gearboxes. It also allows the gearbox to be fastened to the mixing trough without pressure, avoiding unnecessary loads on the gearbox toothing. This special feature is an essential prerequisite for achieving a long gearbox life.

Synchronous coupling [5]

A low-maintenance elastic coupling is installed between the gearboxes to synchronize the two mixer shafts.

Fluid coupling (optional) [6]

The hydrodynamic fluid coupling prevents both mechanical and electrical load peaks. Its use is recommended in particular if unstable electricity supply conditions prevail on site.

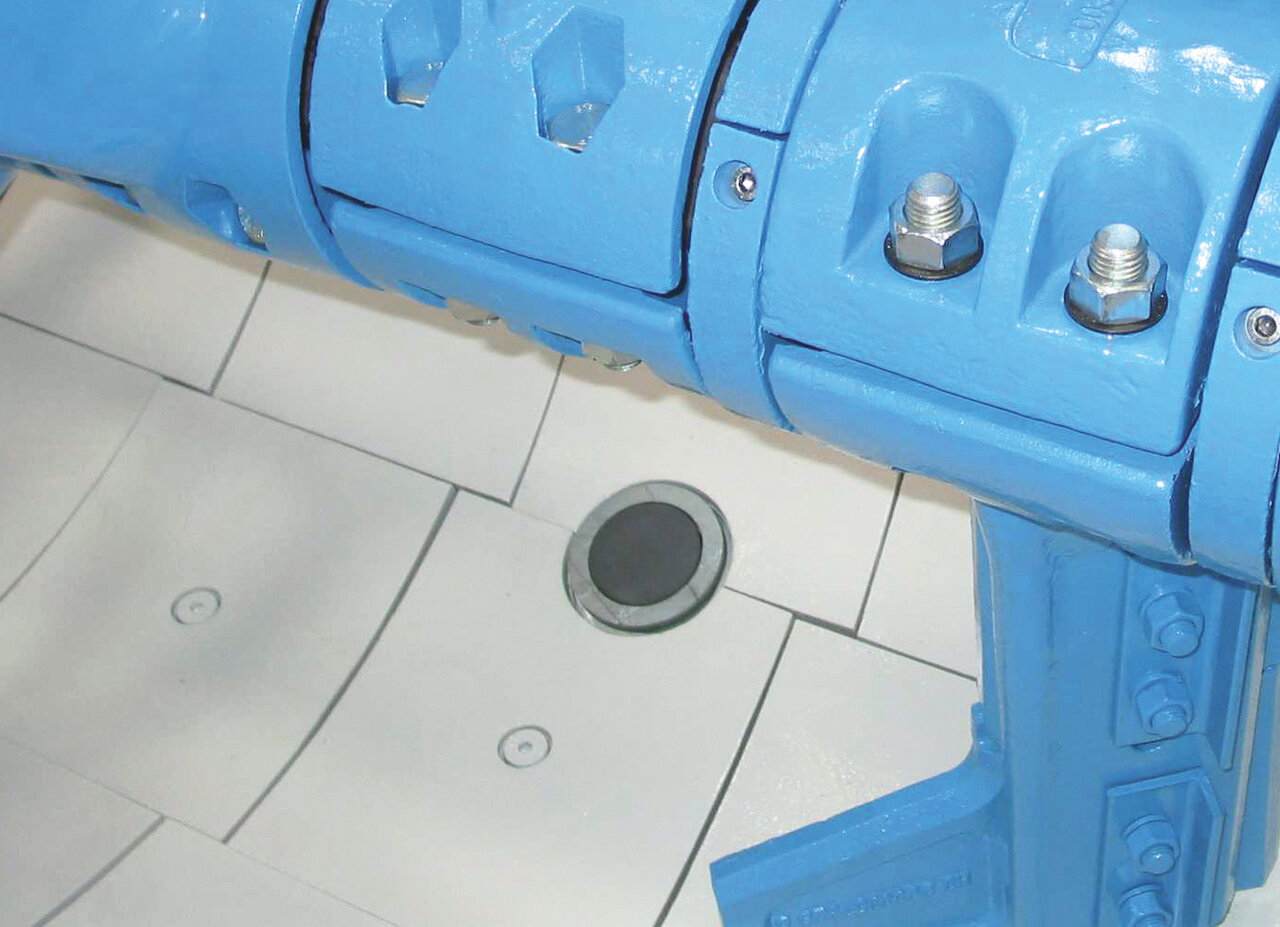

Shaft seal & bearing

The mixer shafts are reliably sealed with axial face seals. The shaft bearings are mounted on bearing lanterns and are physically separated from the shaft seals. This significantly increases the operational reliability of the mixer shaft bearings.

Special designs

Top level of homogeneity for base and top layer

The production of concrete for paving blocks requires highly reliable mixing technology with consistently high levels of homogeneity. The filigree top layer, in particular, requires extremely homogeneous concrete to minimize rejects. The proven twin-shaft batch mixer (type DKX) has been configured by BHS accordingly. The result is a special mixer configuration for concrete blocks with adapted speed, accurate humidity measurement and water dosing, as well as a smooth mixing system and a high-pressure cleaning facility.

Twin-shaft batch mixer (DKX) for the production of concrete paving blocks

Twin-shaft batch mixer (DKX) for the production of concrete paving blocks

Smooth mixing unit, three-dimensional mixing principle and maximum reliability: Efficiency and quality go hand in hand at BHS. The mixer is the key component in the production of concrete paving blocks. Our proven twin-shaft batch mixer can adapt flexibly to your needs and requirements and mix even small batches reliably. Watch the video to learn more about the twin-shaft batch mixer (DKX) in use at the concrete block factory of Excluton.

Homogeneous and reliable

The production of sand-lime blocks requires highly reliable mixing technology with consistently high levels of homogeneity. The BHS twin-shaft batch mixer (type DKXK) meets these requirements while ensuring fast mixing times and reliable, reproducible results. Colors, too, are distributed quickly among the mixing material without leaving any streaks. Due to its design, the twin-shaft batch mixer of type DKXK is less prone to wear and tear than conventional mixing systems. Its rubber trough makes the DKXK ideally suitable for operation as a main mixer for highly abrasive sand-lime blocks. Twin-shaft batch mixers of the DKXK series are available with capacities ranging from 1,000 to 6,500 liters.

Twin-shaft batch mixer (DKXK) for the production of sand-lime blocks

Twin-shaft batch mixer (DKXK) for the production of sand-lime blocks

Watch the video to learn more about the use of the twin-shaft batch mixer (DKXK) at the sand-lime blocks plant of Hermann Peter KG. The customer Hermann Peter uses the twin-shaft batch mixer DKXK with its rubber trough as the main mixer upstream of the reactor.

Our patented Combimix system transforms the BHS twin-shaft batch mixer into a mixer that operates continuously according to the proven twin-shaft technology and allows for adjusting the mixing time. This improves the performance up to 60% compared to batch mixing processes.

Perfect for your concrete laboratory: Our twin-shaft batch mixer in a configuration that produces about 60 l of hardened concrete per batch. The complete mixer is scaled down so that it achieves meaningful test results that are reproducible in the actual production machines.

We can adapt our twin-shaft batch mixers so that a vacuum can be applied during the mixing process. This makes it possible, among other applications, to produce a mixture with particularly low air void contents.

Mixer configuration

Universal mixing unit

Universal mixing unit

This features a 60° arm inclination for the production of ready-mixed concrete, precast concrete, special concretes and many other mixing materials.

Smooth mixing tools

Smooth mixing tools

This serves to reduce adhesions to a minimum, even when processing sticky mixtures.

Coarse particle mixing system

Coarse particle mixing system

For the production of concrete used in dam construction, this system is suitable for aggregates up to 180 mm, depending on mixer size.

Twin mixing mechanism

Twin mixing mechanism

For the production of dry and moist mixtures with many fine particles. This doubling of the mixing arms significantly increases the number of relative movements in the mixture, resulting in shorter mixing cycles.

Diamond-shaped tiles

Diamond-shaped tiles

Diamond-shaped tiles with a material thickness of 19 mm made from optimized chrome chilled cast alloy can be used as mixing trough lining. The service life improves by up to 30 % compared to rectangular tiles.

OPTILONG tiles

OPTILONG tiles

We offer rhombus-shaped tiles with a material thickness of 28 mm for high-wear applications. The variable hardness of the individual tile rows ensures uniform abrasion across all wear zones. This nearly doubles the service life compared to the 19-mm rhombic tiles.

Discharge gate design features

- Solid and robust cast construction

- Centrally located between the two mixing shafts

- Effective sealing due to adjustable gate rails

- Precise regulation of the discharge volume

- Reliable actuation using pneumatic or hydraulic cylinders

Central lubrication

The central lubrication system continuously supplies the internal mixing trough seals with grease during mixing operation. Manual lubrication of the seals is only necessary after each mixer cleaning.

Impulse-driven central lubrication

Impulse-driven central lubrication

The impulse-driven central lubrication system supplies the internal axial face seals with grease. After mixer cleaning or when required, lubrication of the seals can be triggered via the control unit at the push of a button. The running time is freely adjustable.

Fully automatic central lubrication

Fully automatic central lubrication

The lubrication points of the four axial face seals, the four internal mixer trough seals (and, as an option, the other lubrication points of the mixer) are automatically supplied with grease via a PLC controller and by means of a progressive distributor. To lubricate the system after mixer cleaning, it is sufficient to trigger the grease pump via the PLC control.

Options & accessories

Options

Moisture and temperature measurement

Moisture and temperature measurement

Our twin-shaft batch mixers can be equipped with measuring probes from all major manufacturers for measuring the moisture or temperature of the mixture. Due to its design and the intensive, three-dimensional movement of the mixed material, the twin-shaft batch mixer provides particularly reliable measuring results.

Sampling

Sampling

Our twin-shaft batch mixers can be fitted with a front-mounted device for taking mixture samples. This option represents a decisive advantage, especially when it comes to producing demanding concrete formulations.

Installation in electrical terminal box

Installation in electrical terminal box

If required, all electrical wiring can be bundled in a terminal box for easy installation.

Maintenance platforms and footholds

Maintenance platforms and footholds

To ensure easy access for cleaning and maintenance work, our twin-shaft batch mixers can be supplied with maintenance footholds or movable maintenance platforms.

Machine and plant accessories

Technical specifications

Performance data

| Type | Dry charge | Compacted concrete output per batch | Maximum compacted concrete output | Standard drive 3) | Maximum aggregate size | ||||

|---|---|---|---|---|---|---|---|---|---|

| Truck mixer discharge 1) | Open truck discharge 2) | Quality concrete | Hydro dam concrete 4) | ||||||

DKX 0.50 | 0,75 m³ | 0,5 m³ | 73 cycles/h | 37 m³/h | 73 cycles/h | 37 m³/h | 15 kW | 64 mm | - |

| DKX 0.75 | 1,13 m³ | 0,75 m³ | 65 cycles/h | 49 m³/h | 65 cycles/h | 49 m³/h | 22 kW | 64 mm | - |

| DKX 1.00 | 1,5 m³ | 1 m³ | 58 cycles/h | 58 m³/h | 60 cycles/h | 60 m³/h | 37 kW | 64 mm | 80 mm |

| DKX 1.25 | 1,88 m³ | 1,25 m³ | 53 cycles/h | 66 m³/h | 53 cycles/h | 66 m³/h | 45 kW | 64 mm | 125 mm |

| DKX 1.67 | 2,51 m³ | 1,67 m³ | 48 cycles/h | 80 m³/h | 49 cycles/h | 82 m³/h | 55 kW | 64 mm | 125 mm |

| DKX 2.00 | 3 m³ | 2 m³ | 49 cycles/h | 98 m³/h | 53 cycles/h | 106 m³/h | 65 kW | 64 mm | 150 mm |

| DKX 2.25 | 3,38 m³ | 2,25 m³ | 46 cycles/h | 104 m³/h | 50 cycles/h | 113 m³/h | 65 kW | 64 mm | 150 mm |

| DKX 2.50 | 3,75 m³ | 2,5 m³ | 48 cycles/h | 120 m³/h | 56 cycles/h | 140 m³/h | 75 kW | 64 mm | 150 mm |

| DKX 2.75 | 4,13 m³ | 2,75 m³ | 46 cycles/h | 127 m³/h | 55 cycles/h | 151 m³/h | 2 x 45 kW | 64 mm | 150 mm |

| DKX 3.00 | 4,5 m³ | 3 m³ | 44 cycles/h | 132 m³/h | 53 cycles/h | 159 m³/h | 2 x 55 kW | 64 mm | 150 mm |

| DKX 3,33 | 5 m³ | 3,33 m³ | 41 cycles/h | 137 m³/h | 50 cycles/h | 167 m³/h | 2 x 65 kW | 64 mm | 150 mm |

| DKX 3.50 | 5,25 m³ | 3,5 m³ | 42 cycles/h | 147 m³/h | 52 cycles/h | 182 m³/h | 2 x 55 kW | 64 mm | 160 mm |

| DKX 4.00 | 6 m³ | 4 m³ | 39 cycles/h | 156 m³/h | 49 cycles/h | 196 m³/h | 2 x 65 kW | 64 mm | 160 mm |

| DKX 4.50 | 6,75 m³ | 4,5 m³ | 37 cycles/h | 167 m³/h | 51 cycles/h | 230 m³/h | 2 x 75 kW | 64 mm | 160 mm |

| DKX 5.00 | 7,5 m³ | 5 m³ | 35 cycles/h | 175 m³/h | 50 cycles/h | 250 m³/h | 2 x 90 kW | 64 mm | 160 mm |

| DKX 6.00 | 9 m³ | 6 m³ | 31 cycles/h | 186 m³/h | 48 cycles/h | 288 m³/h | 2 x 110 kW | 64 mm | 160 mm |

| DKX 7.00 | 10,5 m³ | 7 m³ | 28 cycles/h | 196 m³/h | 44 cycles/h | 308 m³/h | 4 x 75 kW | 64 mm | 160 mm |

| DKX 8.00 | 12 m³ | 8 m³ | 26 cycles/h | 208 m³/h | 43 cycles/h | 344 m³/h | 4 x 90 kW | 64 mm | 160 mm |

| DKX 9.00 | 13,5 m³ | 9 m³ | 24 cycles/h | 216 m³/h | 43 cycles/h | 387 m³/h | 4 x 110 kW | 64 mm | 180 mm |

1) 30 s mixing time, truck mixer input rate of 0.12 m³/s (0.16 yd³/s) and compactability rate of 1.15.

2) 30 s mixing time, compactability rate of 1.45.

3) Alternative drive power available on request for other applications.

4) For types DKX 1.00 to DKX 4.50 with coarse-grain mixing tools.

Performance data for other materials available on request. All specifications apply to the standard version. Technical data for customized designs may differ from the specified data. All technical data may change due to development. Subject to modification without notice.

Dimensions and weights

| Type | A | B | C | D | E | F | Weight 5) |

DKX 0.50 | 2.310 mm | 1.275 mm | 1.655 mm | 1.550 mm | 1.470 mm | 1.000 mm | 3.100 kg |

|---|---|---|---|---|---|---|---|

DKX 0.75 | 2.540 mm | 1.500 mm | 1.880 mm | 1.550 mm | 1.470 mm | 1.000 mm | 3.600 kg |

DKX 1.00 | 2.400 mm | 1.230 mm | 1.570 mm | 2.040 mm | 1.830 mm | 1.200 mm | 4.040 kg |

DKX 1.25 | 2.590 mm | 1.500 mm | 1.840 mm | 2.040 mm | 1.885 mm | 1.200 mm | 5.200 kg |

DKX 1.67 | 2.920 mm | 1.765 mm | 2.105 mm | 2.040 mm | 1.940 mm | 1.200 mm | 5.700 kg |

DKX 2.00 | 2.590 mm | 1.480 mm | 1.900 mm | 2.470 mm | 2.040 mm | 1.400 mm | 7.500 kg |

DKX 2.25 | 2.850 mm | 1.740 mm | 2.160 mm | 2.470 mm | 2.040 mm | 1.400 mm | 8.100 kg |

DKX 2.50 | 3.100 mm | 1.990 mm | 2.410 mm | 2.470 mm | 2.070 mm | 1.400 mm | 9.000 kg |

DKX 2.75 | 3.150 mm | 1.990 mm | 2.410 mm | 2.470 mm | 2.080 mm | 1.400 mm | 9.600 kg |

DKX 3.00 | 3.410 mm | 2.250 mm | 2.670 mm | 2.470 mm 6) | 2.080 mm | 1.400 mm | 10.200 kg |

DKX 3.33 | 3.410 mm | 2.250 mm | 2.670 mm | 2.470 mm | 2.110 mm | 1.400 mm | 10.400 kg |

DKX 3.50 | 3.250 mm | 1.995 mm | 2.400 mm | 2.855 mm | 2.320 mm | 1.650 mm | 13.400 kg |

DKX 4.00 | 3.500 mm | 2.255 mm | 2.660 mm | 2.855 mm | 2.320 mm | 1.650 mm | 14.000 kg |

DKX 4.50 | 4.270 mm | 2.510 mm | 2.915 mm | 2.855 mm | 2.400 mm | 1.650 mm | 14.700 kg |

DKX 5.00 | 4.260 mm | 2.410 mm | 2.870 mm | 3.180 mm | 2.760 mm | 1.950 mm | 22.000 kg |

DKX 6.00 | 4.790 mm | 2.940 mm | 3.400 mm | 3.180 mm | 2.800 mm | 1.950 mm | 24.000 kg |

DKX 7.00 | 5.290 mm | 3.475 mm | 3.935 mm | 3.180 mm | 2.590 mm | 1.950 mm | 29.000 kg |

DKX 8.00 | 5.440 mm | 3.475 mm | 3.935 mm | 3.180 mm | 2.800 mm | 1.950 mm | 34.000 kg |

DKX 9.00 | 5.980 mm | 4.010 mm | 4.470 mm | 3.180 mm | 2.800 mm | 1.950 mm | 37.000 kg |

5) Weight for standard design without accessories.

6) 2,350 mm for DKX 3.00 in ISO variant.