Optimum recycling of any material

Residual shredder fractions consist of a mixture of recyclable materials. To recover them, the input material must first be shredded. Shredder light fractions (SLF) and shredder heavy fractions (SHF) are generated in phase one. These will have very different compositions based on the input material. Both require compatible process technology in order to extract the valuable materials they contain. As one of the pioneers in residual shredder fraction and material processing, BHS-Sonthofen offers optimal solutions for both fractions.

Having the right technical system is critical for handling both heavy and light materials

When it comes to processing SHF and, more specifically, SLF, recycling plant operators are required to comply with increasingly strict legal regulations. This applies in particular to how shredder residues contaminated with hazardous substances need to be handled. Against this backdrop, it is all the more important to separate 100% of all recyclable raw materials, not least because this also increases the profitability of recycling. BHS experts will recommend the right system and optimum configuration for any shredding application. Whether you are talking about a single machine or the technical design of an entire plant, the solutions we develop for individual applications are tested at our in-house test center.

Shredder light fraction (SLF)

Shredder light fraction (SLF)

Suction is applied in the large shredder’s working chamber to separate the SLF from the SFF. It is not possible to immediately sort the SLF without further mechanical processing due to affinity (the metal particles adhere to other components).

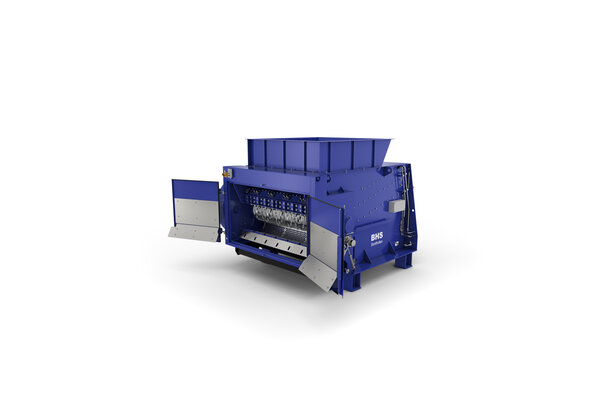

The rotor shredder (type RS) is used to separate composites comprised of multiple materials, some of which are highly entangled. The residual fraction can then be further separated into mineral and organic components. The rotor impact mill (type RPMV) is particularly well suited for the processing of grain sizes of up to approx. 25 mm. It shapes the metallic components into pellets. This makes it possible to readily separate metal fractions from the remaining material in the next step. Components larger than 25 mm in size are processed in the universal shredder (NGU)

Shredder heavy fraction (SHF)

Shredder heavy fraction (SHF)

Shredder heavy fraction (SHF) contains a number of valuable raw materials (metals). The largest share is comprised of aluminum at up to 30%, followed by heavy metals (such as copper, lead, zinc and stainless steel) at up to 20%. The rest is made up of rubber, plastics and mineral components.

In the case of smaller screen fractions of under 25 mm, the metal yield can be increased using BHS technology. The rotor impact mill (type RPMV) cleans and pelletizes the metals. In addition, mineral components are pulverized, which acts to break down the adhesion limits. As a result, the metal fractions can be more effectively recovered during the subsequent separation process.

Video

Efficiently processing shredder fractions

Efficiently processing shredder fractions

The BHS rotor impact mill is a high-performance crusher with a vertical shaft that addresses the needs of the recycling industry. The mill’s unique impeller rotor works together with a toothed anvil ring to subject the inserted material to severe mechanical stress. Material compounds are crushed and separated selectively, entangled materials are isolated, and brittle-hard materials are crushed very finely. At the same time, metals are shaped into balls and cleaned. Watch the video to find out how to optimally prepare shredder fractions for separation by disaggregating composite material and pelletizing metals with the RPMX rotor impact mill.