Dynamic Steam Sterilization

Most spices such as chili, pepper, cumin, or others are heavily contaminated with microorganisms. Many sterilization processes affect product characteristics such as taste, smell or color. Since these are important quality features and selling points, effective and gentle sterilization is crucial to establishing a successful product. To help this effort, BHS has developed automatic plants that guarantee 5-log reduction of microbiological contamination. The plants work with dynamic pressure sterilization, giving you a sterilization result free of color or flavor loss. In addition to quality aspects, our method provides a precisely controllable and particularly short sterilization process.

Mixing of Food Powders

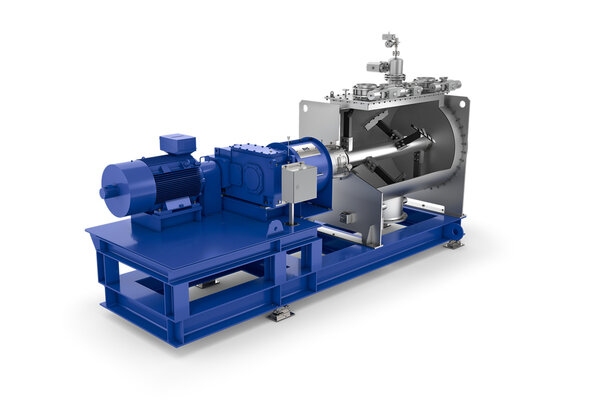

Mixing of Food Powders

BHS offers you highly developed technology for the production of spice mixtures. The mixing of base products with different properties such as particle size, fragility, or bulk density, requires a gentle, yet effective mixing process. The flexible BHS plants for homogenizing solids or solids with liquids deliver to these requirements. The BHS horizontal mixer AVA HTC ensures homogeneous mixing of even the smallest amounts, which constitutes a key economic criterion when the process involves valuable additives. Depending on the base products used, BHS offers you the mixing technology best suited to producing your product to the highest standards.