Solutions

Chemicals

Chemicals & biochemicals

Mineral substances & metal salts

Plastics

Cellulose derivatives

Starch

Dyes & pigments

Catalyst recovery

Pharmaceuticals

Food & Feed

Fly ash & FGD gypsum

Chemical Recycling

Battery materials

Machines

Tests & consulting

After Sales

Sales

Showroom

Applications

Concrete & building materials

Ready-mixed concrete

Precast concrete

Special & high-performance concrete

Hydro dam concrete

Concrete paving blocks

Sand-lime blocks

Dry building materials

Sand & gravel

Road construction

Mining & minerals

Disposal

Mixers

Mixers

Twin-shaft batch mixer (DKX)

Planetary mixer (BPX)

Dry powder batch mixer (DMX)

Twin-shaft continuous mixer (LFK)

Single-shaft continuous mixer (MFKG)

Combimix process (DKXC)

Horizontal mixer (AVA HTC/HTK)

Laboratory mixer

Plant concepts

Used machines

Crushers

Tests & consulting

After-Sales

Contact

Showroom

Solutions

Processes for metal recovery

Light metal scrap

Automotive shredder residue (ASR)

Waste electrical & electronic equipment (WEEE)

Batteries

Incinerator bottom ash (IBA)

Ferrous & nonferrous slags

Metal recovery from fine fractions

Processes for industrial waste

Machines

Impact crushing

Rotorshredder (RS)

Rotor impact mill (RPMV & RPMX)

Impact crusher (PB) & Impact mill (PM)

Rotor centrifugal crusher (RSMX)

Cutting & tearing shredding

Biomass crushers

Plant control systems

Classifying & sorting

Used machinery

Tests & consulting

After Sales

Contact

Showroom

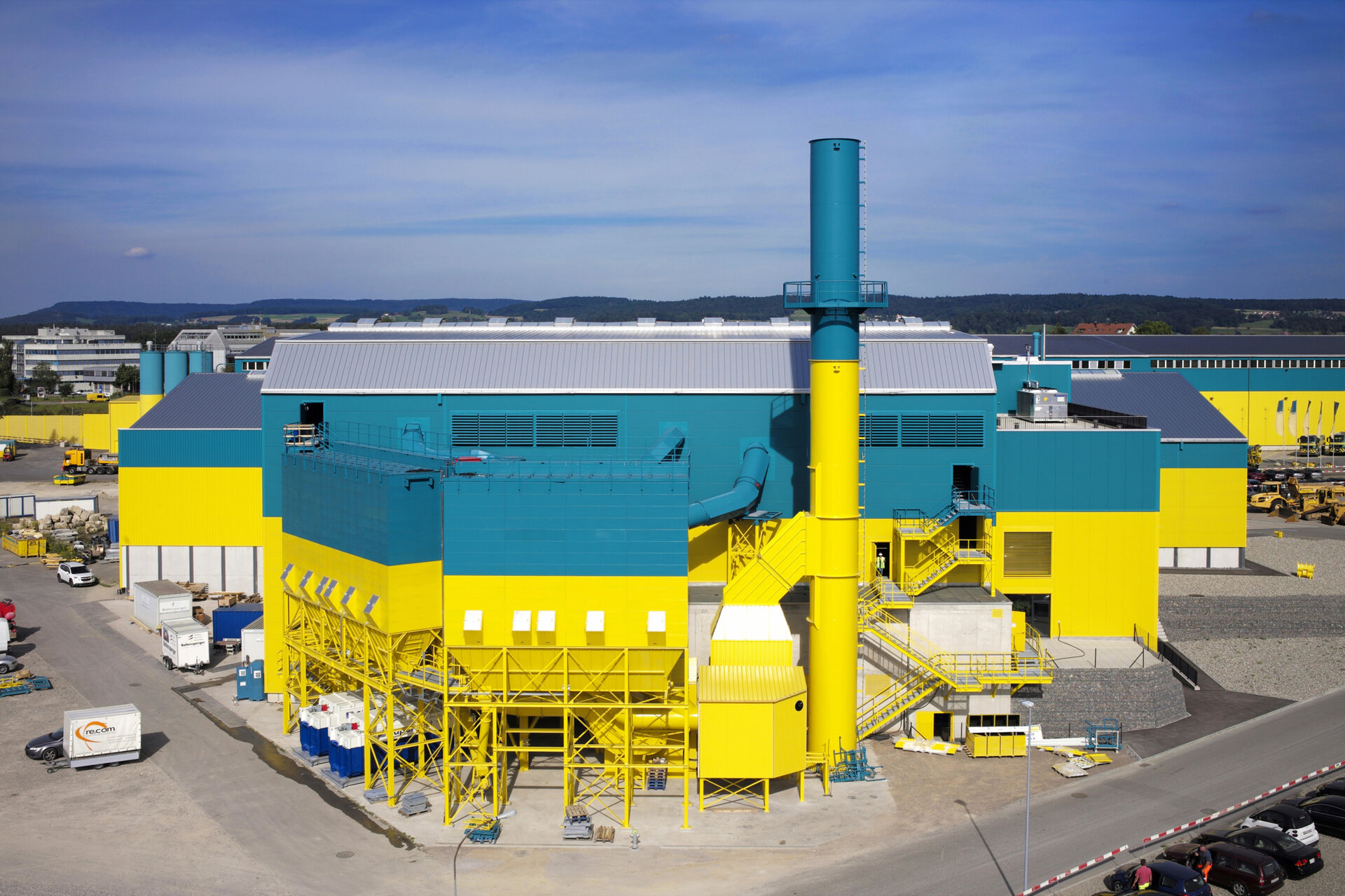

DHZ AG – Extracting concentrated metals from incinerator bottom ash

The key advantage of the BHS system for DHZ AG is that it works based on a dry process. Wet processing would have incurred significant additional costs due to the high requirements associated with water and sludge treatment. BHS delivered two complete lines, from feeding systems through to big bag loading stations. One line processes particle sizes from 8 to 100 mm, and the other takes care of fine processing in the range of 0 to 10 mm.

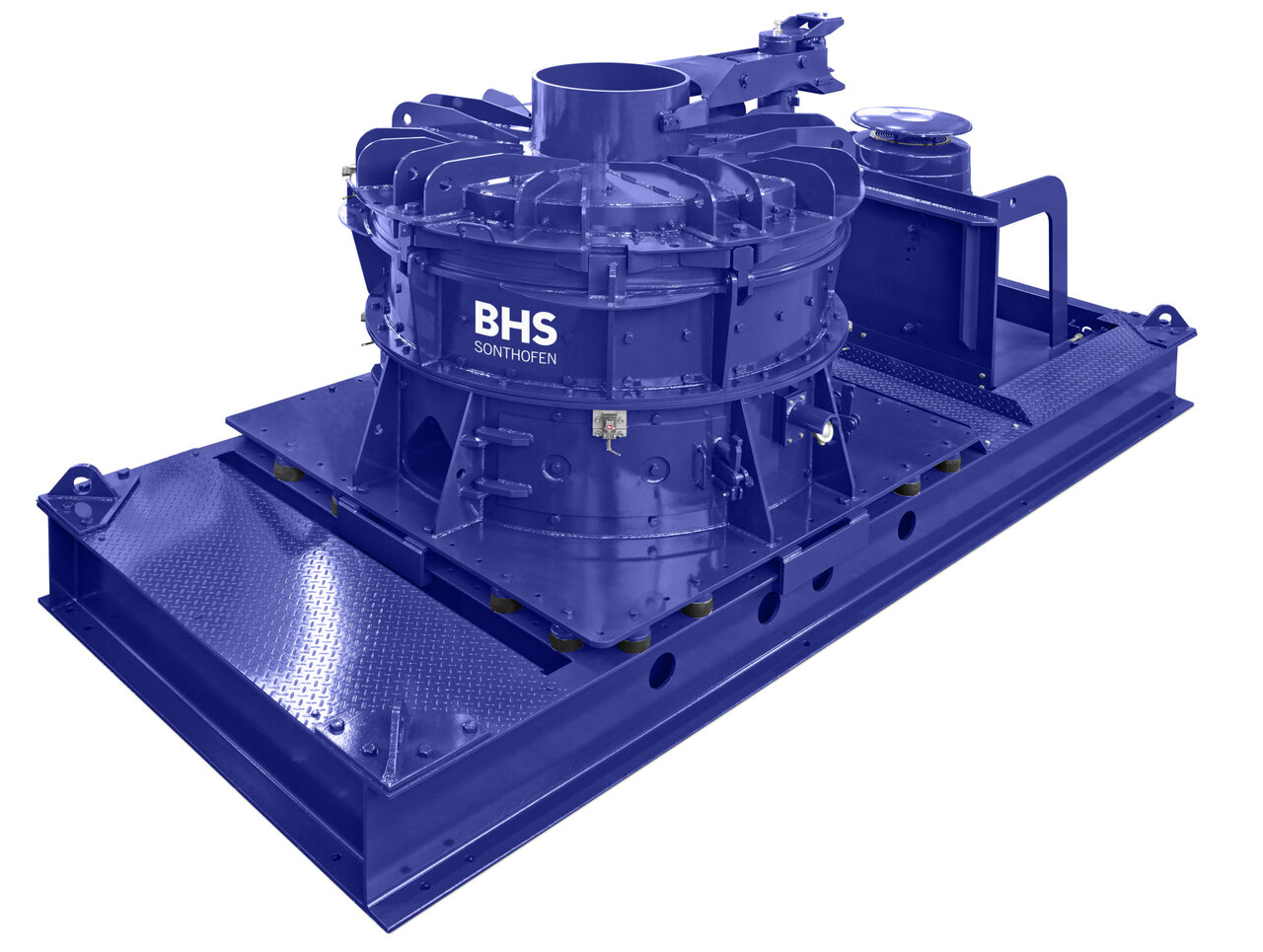

The system comprises an impact mill of type PM 0806, one rotor impact mill of type RPMV 1113 and one rotor impact mill of type RPMX 1516 from BHS-Sonthofen. These machines process granulates with grain sizes from 8 to 100 mm and produce a fine output ranging from 0 to 10 mm. The plants also include screening machines, zigzag sifters, cyclone separators, magnetic drum-type separators and separating tables. The turnkey facility also includes a conveyor system, a dust removal system, steel construction works as well as controlling and visualization.

As a final step, the processed material is cleanly separated by type according to light and heavy non-ferrous metals, ferromagnetic materials, oversized particles and dust, and then filled into big bags.

BHS planned and implemented the entire “supersort®metall” turnkey processing plant for DHZ AG in Oberglatt, Switzerland.

The BHS scope of delivery covered all components for two complete processing plants: from loading to machine technology and through to big bag filling stations.

The two BHS rotor impact mills of type RPMV 1113 and RPMX 1516 are the key components of this processing plant for fine processing of non-ferrous metals from incinerator bottom ash.

The Swiss ‘sweeping bag’ used at DHZ AG in Lufingen contains ash from waste incineration plants.

The head office of DHZ AG, located in the Swiss municipality of Lufingen near Zurich, was built using sustainable materials.