- Concrete & building materials

- Ready-mixed concrete

- Precast concrete

- Special & high-performance concrete

- Hydro dam concrete

- Concrete paving blocks

- Sand-lime blocks

- Dry building materials

- Dry building materials

- Binders

- Sand & gravel

- Aggregates

- Sand

- Clay-and-rock mixtures

- Quartz & glass

- Mineral mixtures

- Road construction

- Asphalt

- Roller-compacted concrete

- Mining & minerals

- Backfilling

- Mineral fertilizers

- Plant concepts

- Retrofitting for mixing plants

- Vertical shaft impactors (VSI)

- Rotor centrifugal crusher (RSMX)

- Rotor impact mill (RPM)

- Horizontal shaft impactors (HSI)

- Impact crusher (PB) & impact mill (PM)

Perfectly homogeneous backfill and landfill

When a mining deposit is exhausted, the cavities created can be filled with suspensions or slurries, among other things. Our mixing systems operating in continuous or batch mode have proven their worth many times over in this field. A high degree of mixture homogeneity in combination with a high degree of binder liberation ensures stability.

Machines you can rely on

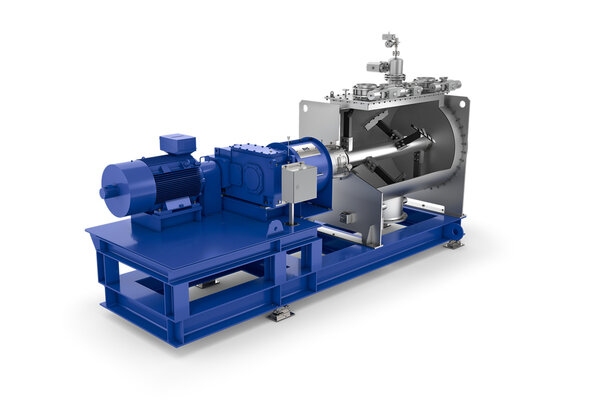

Whether you choose twin-shaft batch mixers (type DKX), single-shaft continuous mixers (type MFKG) or the Combimix system (type DKXC) – you can fully rely on your system creating extremely homogeneous mixtures. All systems work reliably and feature low operating costs as an added benefit. We are also the right partner when it comes to integrating machines into existing facilities with dosing and control technology. Our experts are happy to advise you on the selection of the appropriate solution.