Proven technology for hydro dam concrete

Customers worldwide rely on BHS technology when it comes to mixing earth-moist coarse aggregates for dams. Hydroelectric power plants supply more than a sixth of the energy consumed across the globe – and the trend is shifting in this direction. The dams required for this are impressive and ambitious structures. The materials used to construct them must be of the highest quality. Reliable machines, high throughput rates, perfect homogeneity: Enormous demands are placed on concrete technology during construction – for very good reason.

Low maintenance costs thanks to Optilong tiling

Low maintenance costs thanks to Optilong tiling

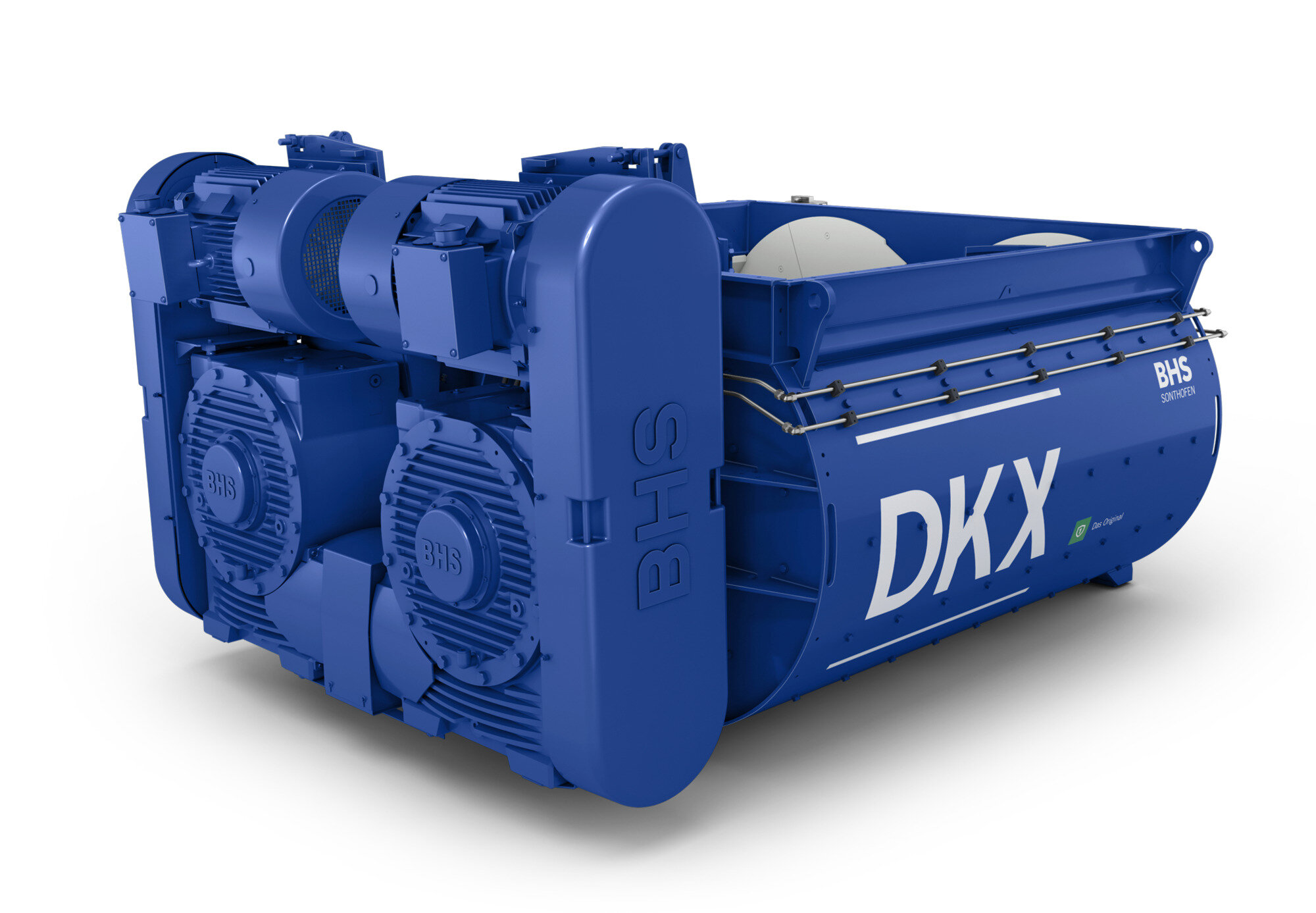

The mixers from BHS-Sonthofen deliver a consistently homogenous mixture after only a short mixing time. Our twin-shaft batch mixers (type DKX) are designed for high capacities and continuous operation. Optilong is our special, durable wear protection that addresses the needs of hydro dam projects. This reduces maintenance and machine downtimes to a minimum.

The right system for any hydro dam project

In addition to our batch mixers, we offer a range of continuously operating twin-shaft continuous mixers. Both mixer systems have proven track records for the construction of RCC dams worldwide. We also offer end-to-end continuous system solutions.

"Longtan" in China

"Longtan" in China

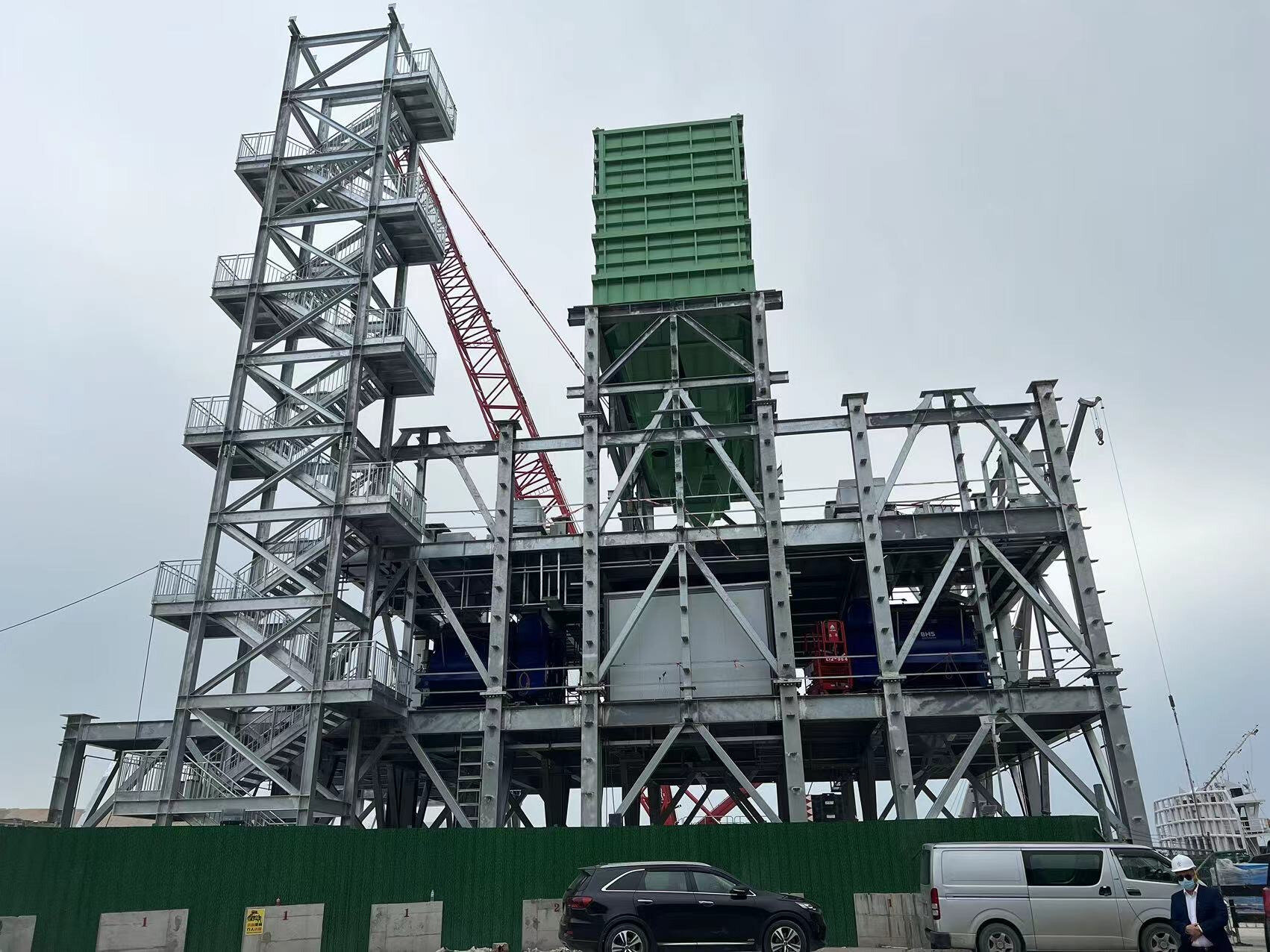

The Longtan hydro dam is located along the Hongshui He River in southern China. With a height of 216 meters, the dam is the highest structure in the world made of roller-compacted concrete (RCC). Two BHS twin-shaft batch mixers of type DKX 7.0 were used to produce the concrete. In total, the two mixers produced around six million cubic meters.

"Dagu" near Zangmu

"Dagu" near Zangmu

Six twin-shaft batch mixers of type DKX 6.0 from BHS produced the concrete needed to build the main embankment of the “Dagu” hydro dam near the Tibetan city of Zangmu. The construction site located 3,700 meters above sea level marks the highest point for BHS mixers to have ever been operated.