Universal Shredder

Universal Shredder

Universal Shredder

The universal shredder of type NGU is a high-speed single-shaft crusher designed for pre- and post-cutting of any material that can be cut. This includes paper, files, data media, textiles, wood, cables, plastics and packaging. It shreds the feed material to a size between 10 and 120 mm.

Highlights

Quick and simple screen replacement

- Segmented screen

- Advantage when shredding files (different protection classes)

Convenient removal of contaminants

- Movable base plate, can be positioned away from the cutting gap

- Easy maintenance

Consistent, clean cutting quality

- Precision-made blades

- Special hardening method

- Blades are easy to adjust and replace

Powerful Drive System

- V-belt drive

- Wide rotational speed range of 80 to 240 RPM (freely adjustable)

- Automatic shutdown if impurities are detected

High throughput rate

- Continuous material supply thanks to load-dependent push-in unit

- Clean cutting quality

High machine uptime

- Heavy-duty machine design

- Easy to remove impurities

- Short maintenance times

- Spare parts available quickly

Economical solution

- Low processing costs per metric ton

- Designed for conventional recycling facilities and for the manufacturing industry

Technical systems

[1] Infeed hopper

The loose feed material is loaded into the infeed hopper, which is individually adapted to the material and type of feeding.

[2] Rotor

The rotor is produced from a solid forged part. A rotating wear protection element protects the rotor edges at the housing mounting point from wear.

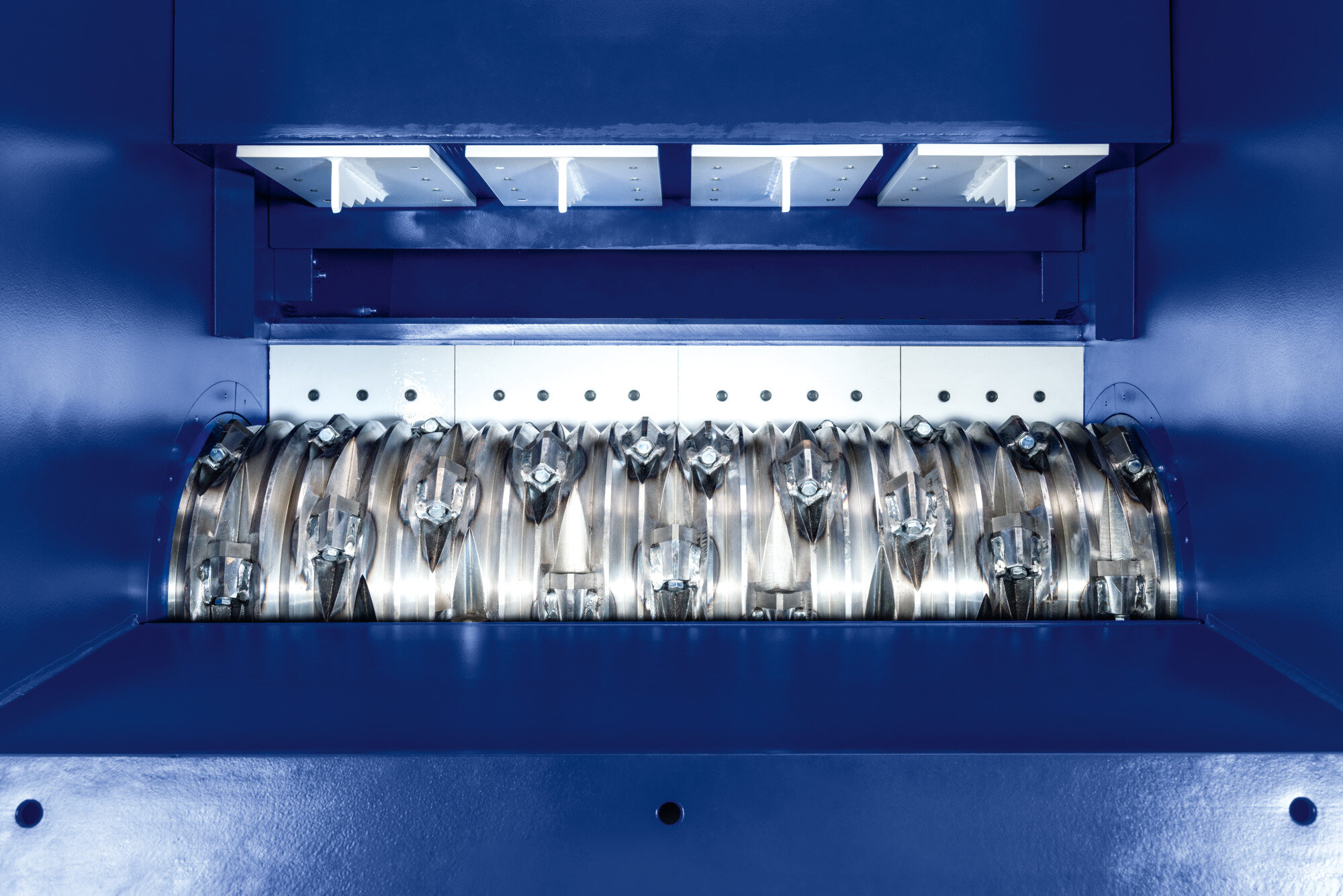

[3] Blades

The blades of the rotor and static blade seat are versatile and can be rotated or replaced in just a few steps. The style, quality and number of blades is configured to match the specific application at hand.

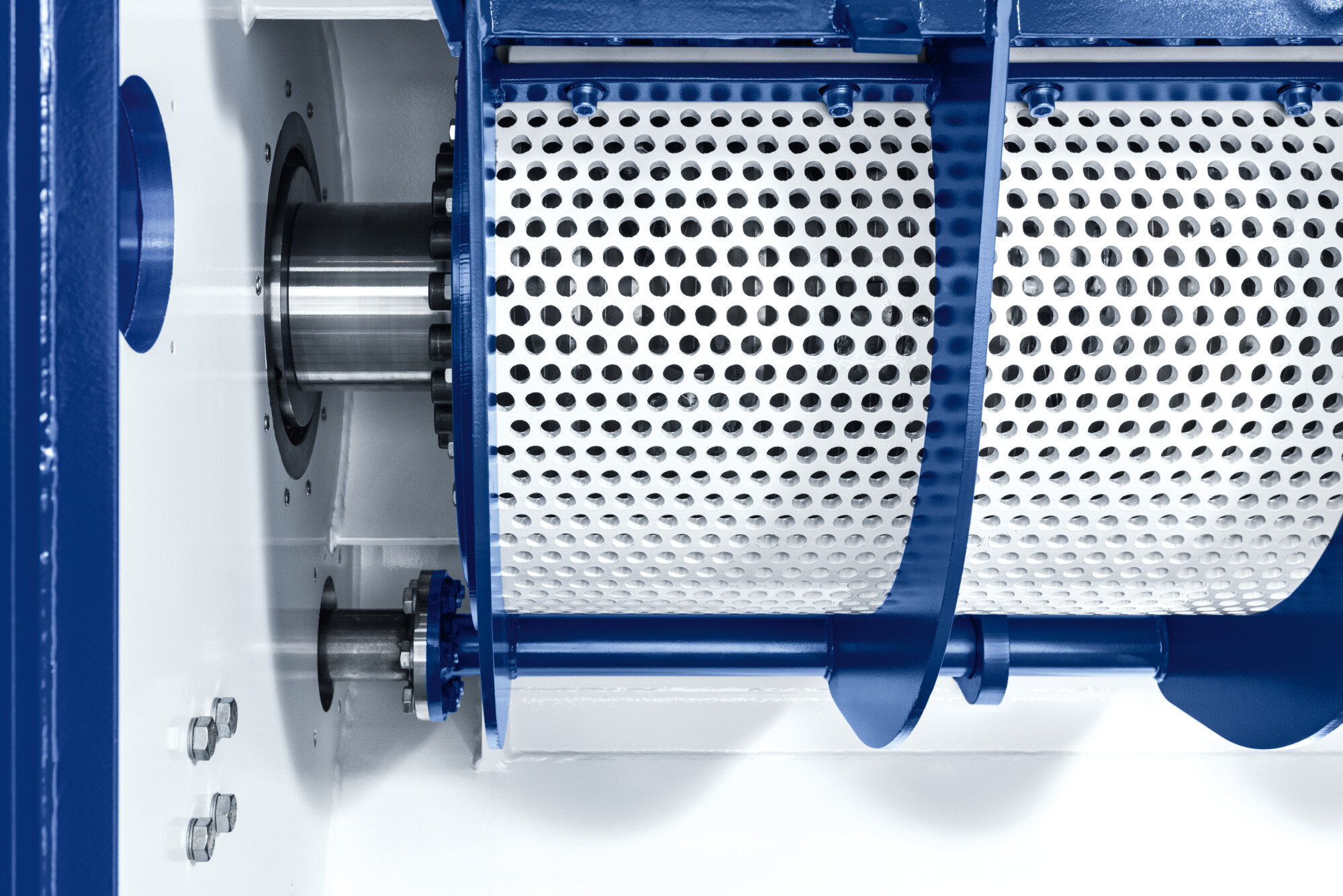

[4] Screen unit

The screen consists of multiple segments that can be replaced individually. The screen support can be rotated downwards. This makes it significantly easier to perform maintenance work.

[5] Drive

The drive is frequency controlled, and the speed of the rotor is freely adjustable between 80 and 240 rpm. As a result, the machine can be configured to account for the properties of different feed materials.

Static blade seat with blade segments

Static blade seat with blade segments

The modular static blade seat is equipped with multiple blade segments. This modular design enables easy adjustment of the blades and ensures consistent cutting quality.

Movable base plate

Movable base plate

A hydraulically movable base plate simplifies the removal of contaminants and facilitates access when performing maintenance work.

Isolated rotor bearing

Isolated rotor bearing

The rotor shaft bearings are located in a double-walled housing. This protects the shaft bearings from the effects of heat and dust, which increases their service life.

Hydraulic pusher unit

Hydraulic pusher unit

A hydraulically driven slide pushes the material along the base plate and toward the cutting system where cutting takes place.

The loose feed material is loaded into the infeed hopper. A hydraulically driven slide pushes the material along the base plate and toward the shredding system. The feed material is shredded between the rotor equipped with blades and the counter-blade mounted on the static blade seat. Once the shredded material reaches a defined particle size, it falls out of the machine through a screen basket. The size of the discharge material is defined by the hole pitch of the screen. It can range from 10 to 120 mm.

Inert design

Variant for hazardous waste

When crushing potentially hazardous recyclable, residual and waste materials (lithium-ion batteries, toxic waste materials, and the like), inertization of the working chamber is required to prevent fires, explosions, hazardous gas leaks or chemical reactions. For process reliability in processing these problematic materials under a protective atmosphere and to protect the health of employees, BHS offers the universal shredder (NGU) in an inertizable design with an external motor.

Technical specifications

Performance data

| TYPE | Drive power | Rotor Speed (max.) | Rotor Diameter x Length | Possible Number of Rotor Blades | Size of Rotor Blades | Number of Static Blades | Number of Static Blade Seats | Throughput Rate | Hole Size of Screen |

|---|---|---|---|---|---|---|---|---|---|

| NGU 0513 | 55 - 110 kW | 80 - 240 rpm | 495 x 1.305mm | 29, 58, 87 | 40 x 40mm | 4 | 1 - 2 | Depending on material | 10 - 120mm |

| 19, 38, 57 | 60 x 60 mm | ||||||||

| NGU 0518 | 90 - 160 kW | 80 - 240 rpm | 495 x 1.795 mm | 40, 80, 120 | 40 x 40mm | 5 | 1 - 2 | Depending on material | 10 - 120mm |

| 27, 54, 81 | 60 x 60 mm |

All specifications apply to the standard design. Technical specifications for customized designs may differ from the data provided here. All technical specifications are subject to change due to continuous development.

Dimensions and weights

| TYPE | A | B | C | D 1) | E 1) | F | Weight |

|---|---|---|---|---|---|---|---|

| NGU 0513 | 2.474 mm | 3.250 mm | 1.750 mm | 500 mm | 220 mm | 1.570 mm | 9 tons |

| NGU 0518 | 2.964 mm | 3.250 mm | 1.750 mm | 500 mm | 220 mm | 1.570 mm | 11 tons |

1) With standard hopper and standard steel construction