Recovering reusable materials from discarded electronic devices

The amount of electronic waste is growing by the year. Millions of tons are produced worldwide annually, and the number of discarded devices is increasing all the time. Mobile phones, televisions, computers and washing machines contain valuable materials that are in strong demand.

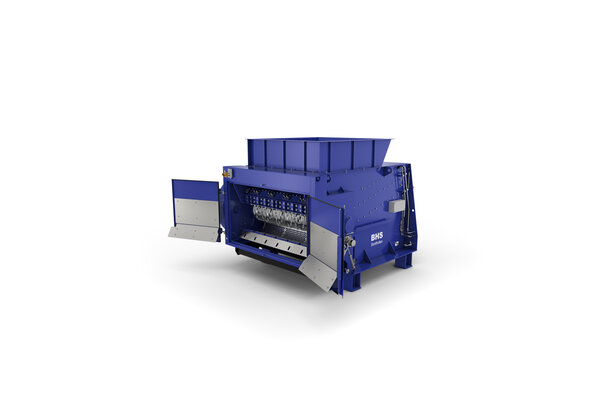

When processing electrical and electronic scrap, the goal is to obtain secondary raw materials that are as pure and marketable as possible and contain zero harmful substances. At the start of the process, the waste materials need to be broken down. BHS recycling technology is perfect for the job.

BHS-Sonthofen supplies individual machines for special process steps and complete systems for the recycling of electronic waste, which ranges from small household appliances to lithium-ion batteries.

Video

Recycling of electrical and electronic waste (WEEE)

Recycling of electrical and electronic waste (WEEE)

Just waste? Every year, a wide range of electrical and electronic scrap materials accumulates - from old cell phones and coffee machines to printers. But not all e-waste is the same, depending on the region and origin. The range of input material is wide. It is a real challenge to recover the maximum amount of valuable metallic raw materials using a standard process. Through continuous investment in the development of our own recycling technologies, the process solution for metal recovery from a wide range of electrical and electronic waste has been further improved. Our turnkey process solutions offer optimum flexibility for a wide variety of WEEE thanks to trials in our in-house test center and intelligent pre-sorting. Our solution adapts to customer requirements, ensuring valuable and marketable metal concentrates and secondary raw materials.

Processing of copper armatures and electric motors

Processing of copper armatures and electric motors

Optimized recovery of copper from motor armatures and electric motors – also known as meatballs – at a customer facility in France thanks to selective shredding using the BHS rotor shredder of type RS 2018. The fed copper armatures and electric motors are first shredded and separated using the RS unit. They can then be separated into pure fractions (e.g., copper, iron, etc.).

Large and small household appliances

Small household appliances

Small household appliances

This includes vacuum cleaners, kitchen appliances, hair clippers/dryers, irons, toasters, grills and fryers. Due to the wide variety of appliances that exist, it is necessary to pre-shred them in our RAPAX, which is specifically designed to handle such tough tasks. As soon as the feed material has been reduced to the desired size, it exits the machine through the bottom. The rotor shredder (type RS) performs the next step of disaggregating the composites. Finally, the rotor impact mill (type RPMV) finely processes and sorts the material into pure fractions. The rotary shear (type VR) and universal shredder (type NGU) are used for processing material substreams.

Large household appliances

Large household appliances

You need a powerful machine to handle an entire dishwasher, washing machine or stove. Our RAPAX is suited for the tearing pre-shredding of especially large or bulky materials. The rotor shredder (type RS) then disaggregates composite materials to help facilitate the subsequent recycling of reusable materials.

Cables & circuit boards

Cables

Cables

There are many types of cable waste, ranging from wires to heavy ground cables that come in a wide variety of diameters and configurations. Every cable contains electrically conductive materials (copper, aluminum, etc.), a plastic sheath, and, in some cases, lead, textiles and steel. Our BHS solutions are also able to handle many different types of cables.

Coarse shredding is performed by the rotary shear (type VR), which also cuts thick cable strands down to lengths of approx. 100 mm. The BHS universal shredder (type NGU) shreds the cables down to even smaller pieces of 10 to 20 mm. This is also the step in which composite materials are largely broken down. The rotor impact mill (type RPMX) is the perfect choice for the third (optional) stage in the shredding process. These machines are able to further disaggregate and granulate fine cables, in particular (telephone wires, for example).

Circuit boards

Circuit boards

Printed circuit boards consist of an electrical insulator (for example, plastic or hard paper) with conductive connections attached to it.

The rotary shear (type VR), a low-speed, high-torque twin-shaft crusher, is perfect for the job of pre-shredding such electrical components. The universal shredder (type NGU) is the right tool for phase two of the shredding process: The high-speed, single-shaft crusher cuts the material to the desired particle size. The rotor impact mill (type RPMX) is an excellent choice for the further separation of composites.

Batteries

Innovative technologies from BHS for environmentally friendly recycling

Every new technology introduces new challenges. BHS is constantly developing innovative methods to overcome them.

Lithium-ion batteries

Lithium-ion batteries

Batteries and accumulators must first be discharged before they can be shredded in a safe and environmentally friendly manner. We use the rotary shear (type VR) and our universal shredder (type NGU) to crush and shred such devices. If the batteries have not been treated with a thermal process at high temperatures, sparks in the machine can cause the electrolyte to catch fire. In order to eliminate this risk, both machines feature a gas-tight design and operate in a nitrogen atmosphere.