Rotor centrifugal crusher

Rotor Centrifugal Crusher

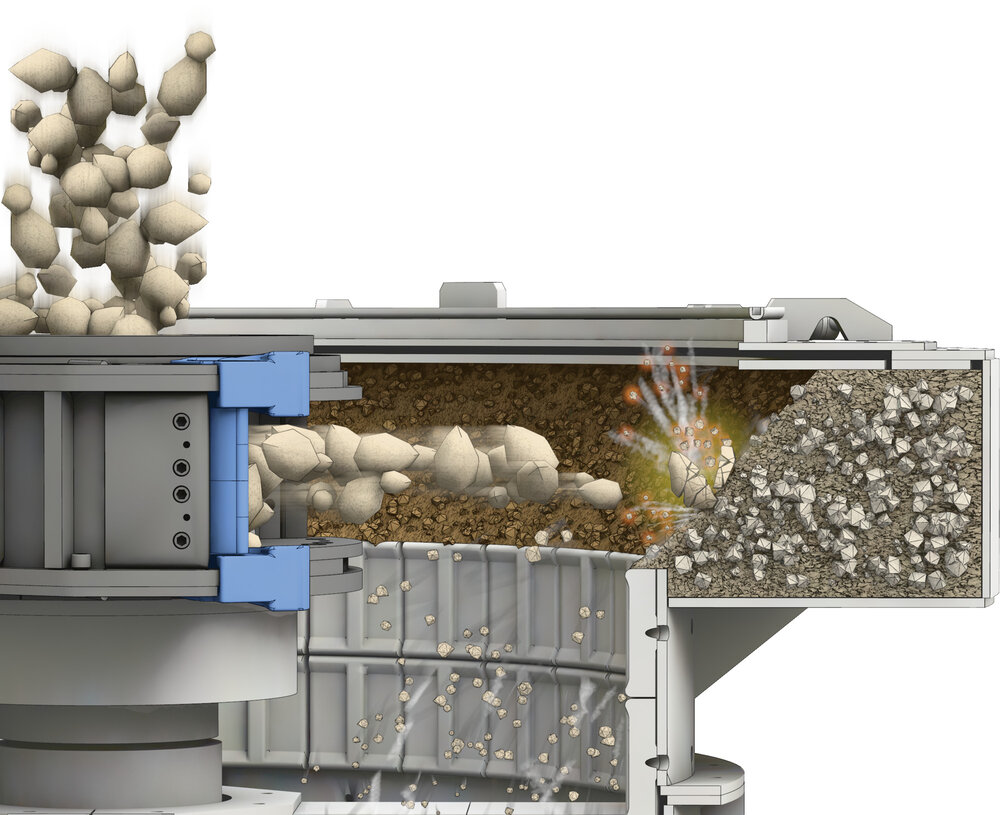

The rotor centrifugal crusher of type RSMX is a high-performance crusher and is used to selectively crush and refine all types of minerals, from soft to hard and fragile to extremely abrasive. Depending on its size, high throughput rates can be achieved.

Every single particle of the input material undergoes extreme acceleration due to the centrifugal force in the rotor and is hurled against the impact wall. The impact wall can either consist of an anvil ring or alternatively of a material bed. Clogging is avoided due to the generous dimensioning of the rotor and housing. The crushing results can be substantially controlled and optimized by selecting a suitable speed.

Highlights

Generating valuable end products

Creating high-quality cubical products

- Very high cubicity of the end product thanks to intense impact stress (every single particle undergoes extreme acceleration and is hurled against the impact wall)

- Consistent quality of end products

- Uniform crushing results despite increasing wear and tear

- Due to the nature of the system, random effects are prevented while the material is being shredded.

- Advantages compared to conventional crushers

Targeted, selective size reduction

- Soft material is shredded to smaller sizes thanks to use of selective impact crushing on every single particle

- High-precision crushing of brittle aggregate elements or previously damaged feed material

- Significant increase in quality of end products (Los Angeles values, frost resistance)

- End product is enriched in the case of raw ores and industrial minerals composed of elements that vary in strength

Superior machine technology

Globally proven twin-chamber rotor

- Specialized in vertical shaft crushers (rotor and vertical shaft impact crushers)

- Patented twin-chamber rotor

Unit ready for operation

- Ready-to-install unit consisting of machine and drive train on a base frame

- Easy access due to large cover that can be raised hydraulically and pivoted by 360°

Reliable greasing

- Recirculating oil lubrication with cooling and integrated monitoring ensures low-maintenance, reliable operation

Easy maintenance and high availability

- All parts that are exposed to stress are protected by easily replaceable wear parts

- No need for build-up welds or to keep a second rotor in stock

Vibration absorption

- Rubber spring elements keep vibrations generated during operation away from supporting structure

- Electronic vibration monitor causes machine to shut down if it registers excessive vibrations

Technical systems

Operating principle

The input material is supplied to the center of the rotor centrifugal crusher from above. Once in the rotor, the material enters the two large centrifugal chambers, which ensure blockage-free operation and high throughput rates.

The input material is propelled outwards with great force. This is followed by targeted impact against the fixed impact wall or sand bed, resulting in cubically shaped grains.

Operating principle with anvil ring (top view)

Operating principle with anvil ring (top view)

Operating principle with sand bed (side view)

Operating principle with sand bed (side view)

Compared to the multi-chamber version, less air is transported in the patented twin-chamber rotor. This has a positive effect on power consumption. The energy saved here can then be used to increase throughput rates, and the dust removal system can be operated at reduced power.

The maximum possible material outlet sizes (89° per rotor side) are made possible by the open design of the patented twin-chamber rotor. This significantly reduces the risk of blockage.

A material bed forms along the centrifugal chambers in the BHS twin-chamber rotor to provide autogenous wear protection. Compared to conventional rotors, the number of wear parts that are required is reduced to a minimum.

Highly flexible

Depending on the input material and the required shredding results, the BHS rotor centrifugal crusher can be operated with either an anvil ring or a sand bed as the impact wall.

Typical applications with an anvil ring

Typical applications with an anvil ring

- Production of high-grade cubical chippings and sand from medium-hard, moderately abrasive feed material such as gravel, limestone, dolomite, diabase, basalt, andesite, broken bricks and cement clinkers

- Selective crushing of molasse and other conglomerates, moderately abrasive slags, industrial minerals, overburden, etc.

- Recycling of asphalt and non-reinforced construction waste

Typical applications with sand beds

Typical applications with sand beds

- Production of high-grade cubical chippings and sand from highly abrasive feed materials such as gravel, granite, porphyry, gneiss, graywacke and granular quartz.

- Granulation of highly abrasive materials such as aluminum oxide, ferrosilicon, abrasives and glass.

- Selective crushing of slags from steelworks, waste incineration plants and similar facilities.

Options & accessories

Options & accessories

Reinforced cover lining

In order to increase the service life, a cover with reinforced lining can be selected as an option.

Electro-hydraulic cover opening

For even faster opening of the machine cover for maintenance and inspection, an optional electro-hydraulic actuation mechanism is available.

Quick changing system

To reduce installation times, the quick-change system allows you to replace the entire set of anvil rings with the aid of a hoist if there is sufficient space available to do so.

Installation in electrical terminal box

If required, all electrical wiring can be bundled in a terminal box for easy installation.

Intensive cooling

In the event of high ambient temperatures or if the material to be processed is hot, a supplementary lubrication unit featuring a larger storage volume and stronger cooling power can be provided.

Air cannon

In order to reduce material deposits in the outlet area, the crusher can be optionally equipped with air cannons.

Control unit

To provide an alternative means of operation, the machine can be shipped with a PLC controller (including touch panel) and a frequency converter if required. This allows for autonomous operation and monitoring of the machine’s functions.

Peripherals

We can also provide the steel construction, storage bunker and metering equipment, feed and discharge equipment, and dust capture systems – all adapted to your specific applications.

Technical specifications

Performance data

| TypE | Rotor diameter x height | Circumferential speed | Drive power | Throughput rate 2) | Input size 3) |

|---|---|---|---|---|---|

RSMX 0913 | 930 x 135 mm | 70 m/s | 75 - 160 kW | 30 - 75 t/h | 45 - 56 mm |

| RSMX 0922 | 930 x 220 mm | 70 m/s | 90 - 160 kW | 30 - 90 t/h | 56 - 70 mm |

| RSMX 1222 | 1.200 x 220 mm | 70 m/s | 160 - 400 kW 1) | 100 - 400 t/h | 80 - 100 mm |

1) Drive power bigger than 400 kW available on request as a twin drive.

2) The throughput rate depends on the circumferential speed of the rotor and the grading curve of the input material.

3) The input size depends on the type of rock, the circumferential speed of the rotor and the percentage of maximum particle size in the grading curve (screened through square mesh).

Dimensions and weights

| TypE | A | B | C | D | E | F | Weight 4) |

|---|---|---|---|---|---|---|---|

RSMX 0913 | 3.950 mm | 2.400 mm | 2.355 mm | 318 mm | 990 mm | 2.380 mm | 7.500 kg |

| RSMX 0922 | 3.950 mm | 2.400 mm | 2.355 mm | 318 mm | 990 mm | 2.380 mm | 7.800 kg |

| RSMX 1222 | 5.080 mm | 2.860 mm | 2.675 mm | 457 mm | 1.468 mm | 2.720 mm | 12.100 kg |

4) Weight for standard design without motor and accessories.