Rotary shear

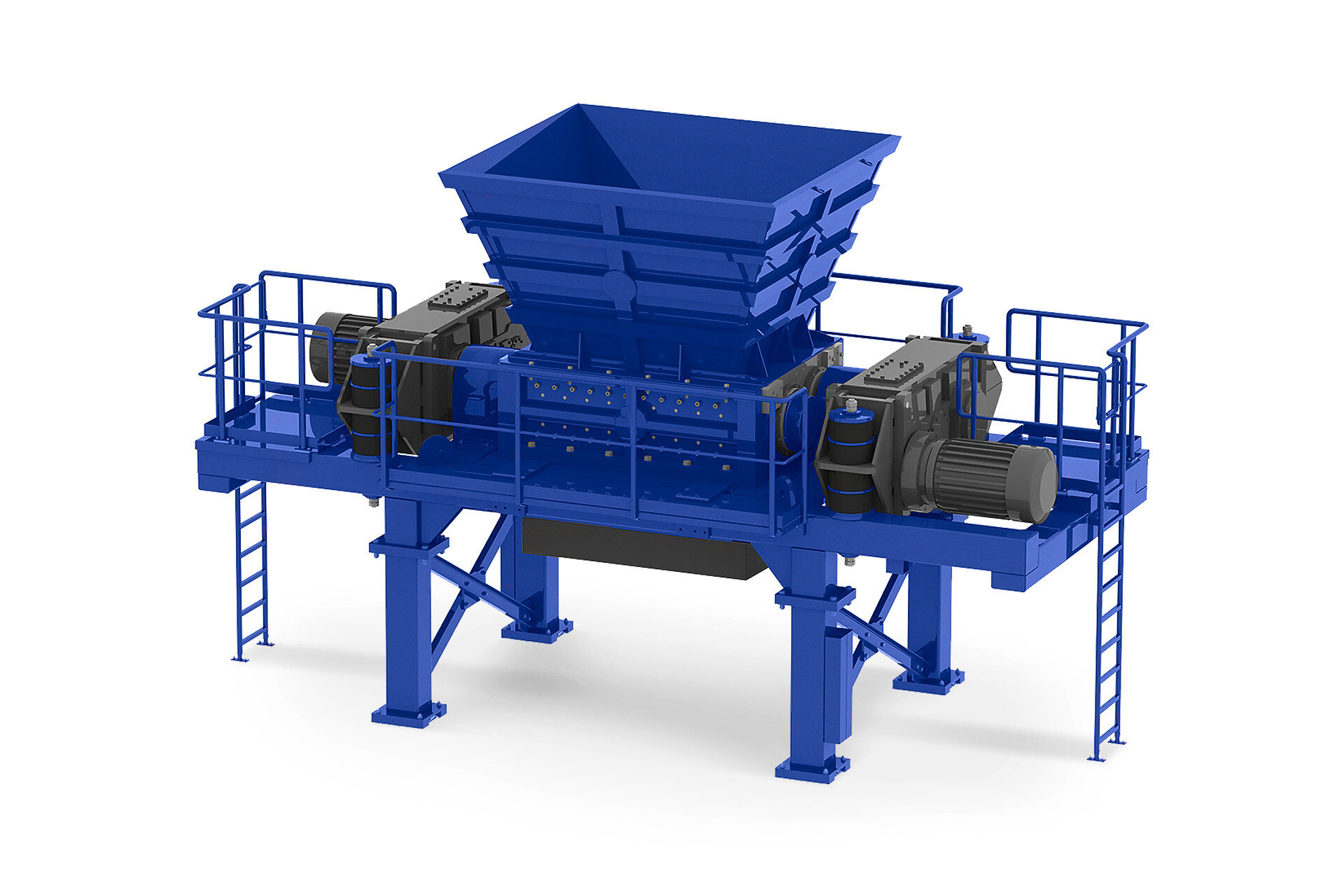

Rotary Shear – Robust and versatile heavy-duty twin-shaft shredder

The BHS rotary shear of type VR is a low-speed, high-torque twin-shaft shredder for the shredding of large, bulky waste materials or elastic feed material. Our inert design variant of the rotary shear (VR) is mainly used in battery recycling for the safe pre-shredding of bulky battery modules or packs. In addition, the inert design variant can also be used for the safe shredding of toxic waste materials, from which a pumpable mass is produced in SMP plants for subsequent thermal utilization. It also reduces large-volume input materials as well as parts with high unit weights. The rotary shear reliably achieves superior shredding performance.

Inert design

Inertizable designs for absolute process safety

When shredding and processing potentially hazardous materials such as batteries or toxic waste, it is necessary to inert the working chamber to prevent fires, explosions, hazardous gas leaks, or chemical reactions. For process reliability in processing these problematic materials under a protective atmosphere, BHS offers the rotary shear in an appropriate, inert design.

In the BHS process solution for the safe and economical recycling of lithium-ion batteries, the inert design is an integral part of a battery recycling plant for the safe pre-shredding of bulky battery modules or battery packs.

Highlights

On-target shredding results

- Reliable shredding to the desired granulation

- Uniform material density

Clean and consistent cutting quality

- Precision-made blades with narrow tolerances

- Easy-to-replace blades

- Long blade life thanks to special hardening method

Low operating costs

- Wear parts can be reconditioned and reused several times

- Inexpensive to replace set of shearing shafts

High system availability

- Long-lasting wear parts

- Patented bearing shell bridge system for fast and simple replacement of shearing shafts

High throughput rates

- High-torque drive

- High hourly output thanks to optimized geometry of shearing tools

- Ready for use in three-shift operation

Flexibility

- Disaggregation of a large number of input materials

- Tearing tools can reliably process even voluminous or bulky feed material due to relatively large shaft diameters

- Optional push-in unit

One-piece machine housing

- Heavy duty thanks to single-piece, welded steel construction

- No screw connections which are prone to causing malfunctions

- Long machine life

Torque buffering

- Improved operational reliability

- Prevents damage

Technical systems

Optimized cutting and shredding

Two counter-rotating shear shafts grasp and shred the input material. Each shaft is equipped with several high-precision cutting tools that function like scissors. There are gripping hooks at the tip of each tool that guarantee fast and reliable material infeed. Scrapers are placed on the outside of the shaft to prevent material from sticking. The piece size of the final product is affected depending on the cutting blade width.

[1] Infeed hopper

The machine is equipped with a large, central infeed hopper. In addition to standard solutions, customer-specific hoppers are also available.

[2] Machine housing

The machine housing is designed as a highly robust, one-piece, welded steel construction. This allows the machine to absorb extremely high forces without difficulty.

[3] Rotor with shearing tools

The material is shredded between two rotor shafts rotating in opposite directions towards the center. The shearing tools are specially positioned on the rotor shafts to ensure a high crushing performance.

[4] Scrapers

The scrapers are attached to the side walls of the machine housing and reach in between the shearing discs. They prevent material from adhering to and building up on the rotating shear discs. If discs wear out, each one can be replaced individually.

[5] Drive

Every shaft is powered independently. The drive consists of a spur gear and an electric motor from well-known manufacturers. In case of an overload, the drive allows the shearing disc to be retracted by changing the direction of rotation.

[6] Torque buffering

As a standard feature, each drive unit is protected by large torque buffers. Every buffer unit consists of four solid rubber elements mounted to a robust welded steel structure.

[7] Hydraulic Pusher Unit

A hydraulic pusher device is available as an option. It ensures continuous material infeed when processing low-density, light or bulky feed stock.

Frequency Inverter

The machine can optionally be equipped with an electronic frequency inverter. This allows the speed to be adapted to individual process conditions and prevents the generation of costly peak currents.

Quick changing system

Quick changing system

The shear shafts’ quick-change system consists of a specially designed quick coupling located between the shear shaft and the gearbox and a patented bearing shell bridge. The quick coupling is screw-fastened and makes shaft changing possible without having to disassemble the drive system. The bearing shell bridge can be easily removed. Once this is done, it is then possible to remove the shear shafts by lifting them up.

Two rotor shafts, which rotate in opposite directions towards the center and collect the input material, are enclosed in a heavy-duty housing. Each shaft is equipped with several high-precision cutting tools that function like scissors. There are gripping hooks at the tip of each tool that ensure fast and reliable material infeed. The hydraulic pressure unit can be used to assist as needed in individual cases. Scrapers are placed on the outside of the shaft to prevent material from sticking to the rotating cutting tools. The particle size of the end product greatly depends on the width of the selected cutting blade.

Technical specifications

Performance data

| TYPE | Drive power | Rotor speed (max.) | Rotor diameter x length | Number of cutting tools | Width of cutting tools |

|---|---|---|---|---|---|

| VR 0912 | 2 x 55 kW | 18 rpm | 480 x 1.200 mm | 12 per shaft | 50 mm |

| VR 1215 | 2 x 90 kW | 18 rpm | 530 x 1.500 mm | 13 per shaft | 58 mm |

| VR 1518 | 2 x 160 kW | 11 rpm | 730 x 1.800 mm | 11 per shaft | 80 mm |

All specifications apply to the standard design. Technical data for customized designs may differ from the specified data. All technical data may change due to development. Subject to modification without notice.

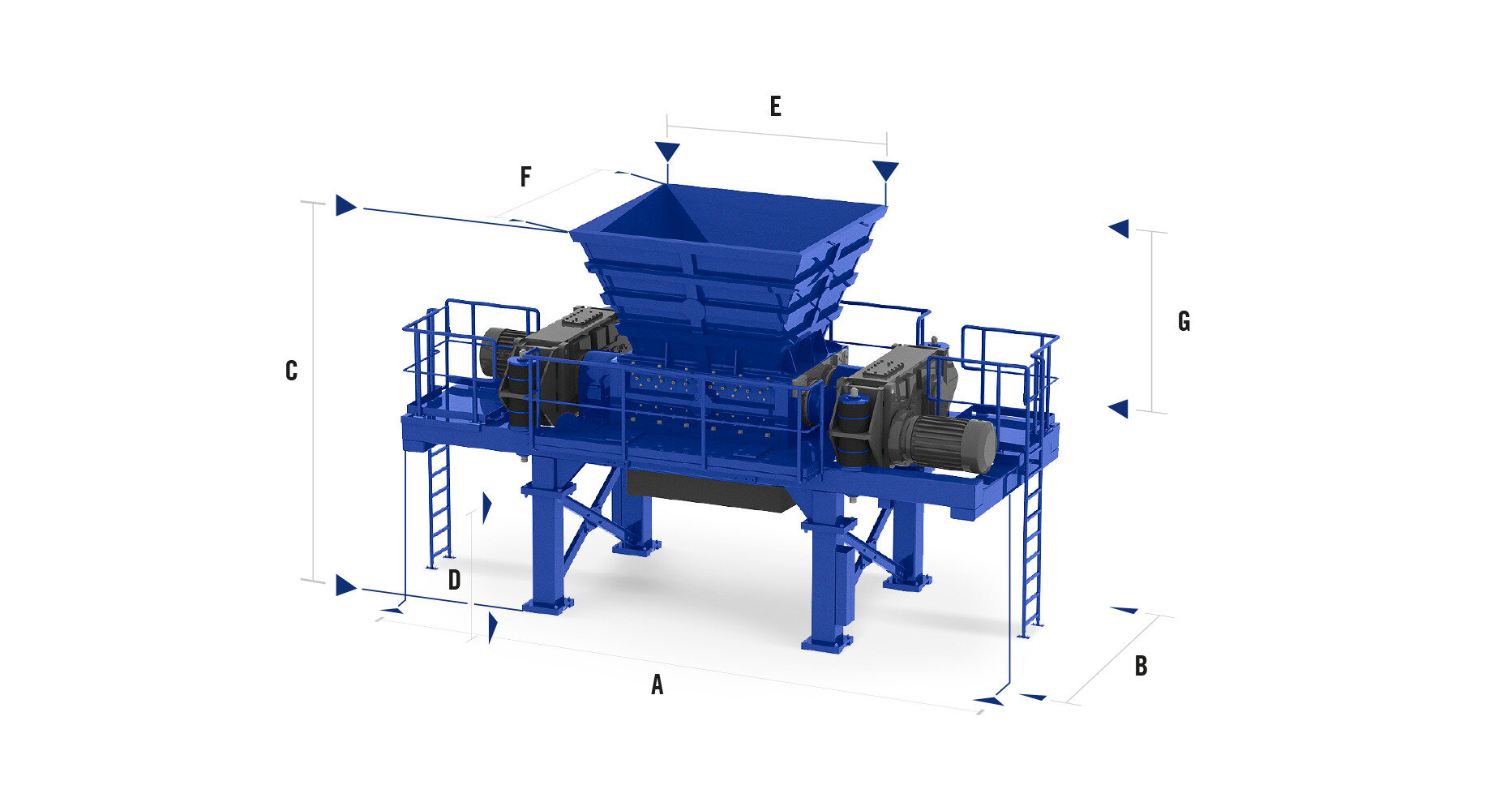

Dimensions & weights

| TYPE | A | B | C | D | E | F | G | Shredding chamber length x width | Weight |

|---|---|---|---|---|---|---|---|---|---|

| VR 0912 | 5.200 mm | 2.200 mm | 4.000 mm | 1.500 mm | 2.500 mm | 2.300 mm | 1.500 mm | 1.200 x 900 mm | 14 ton |

| VR 1215 | 5.500 mm | 2.500 mm | 4.200 mm | 1.500 mm | 2.800 mm | 2.500 mm | 1.500 mm | 1.500 x 1.200 mm | 22 ton |

| VR 1518 | 7.600 mm | 3.000 mm | 4.800 mm | 1.500 mm | 2.900 mm | 2.800 mm | 1.500 mm | 1.800 x 1.500 mm | 40 ton |