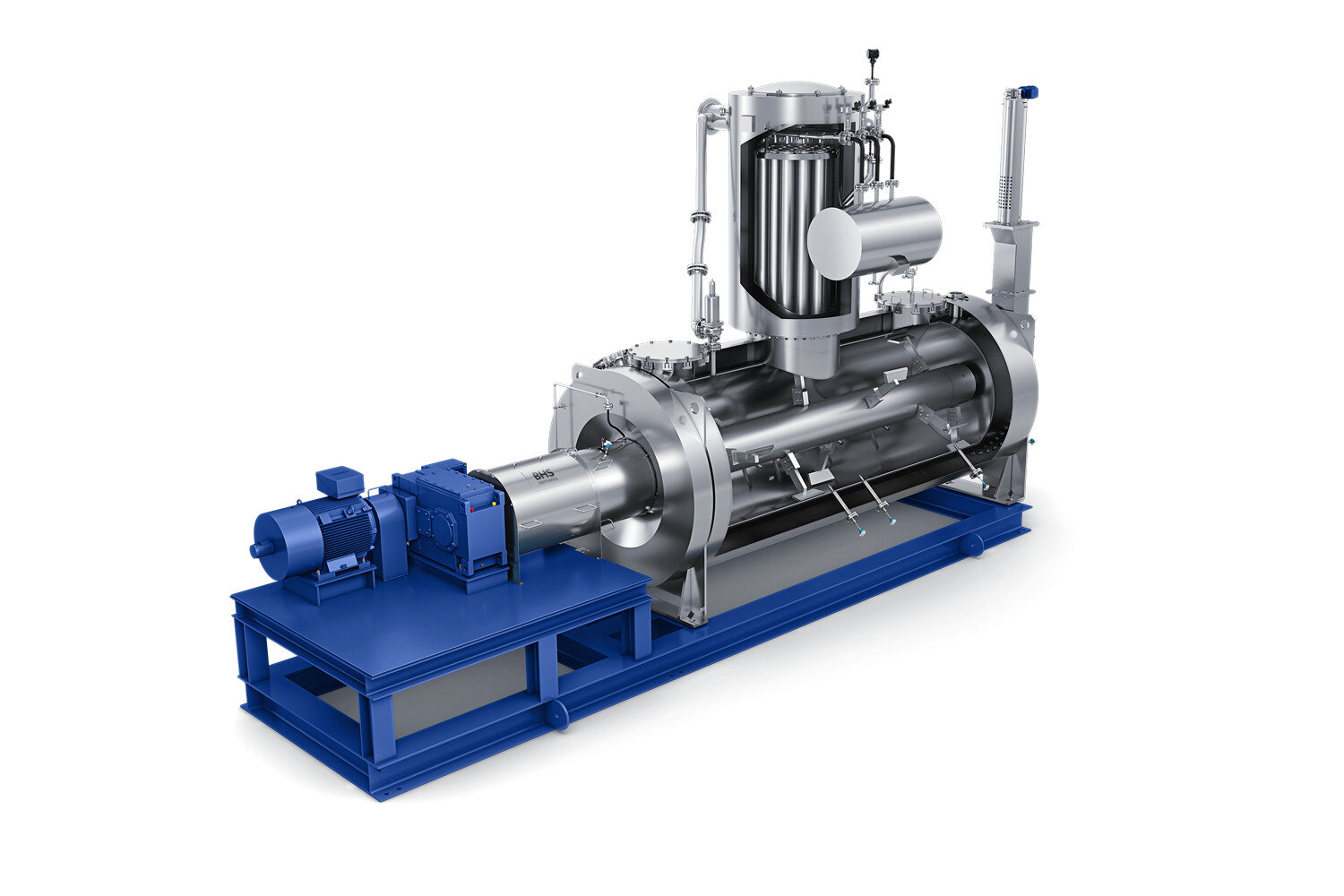

Processing of anode and cathode materials

High temperature is a critical factor in the processing of high performance anode and cathode materials. BHS has developed a high-temperature reactor, which opens up new possibilities for the production of battery materials. In addition the dynamic BHS drying principle ensures high product and temperature homogeneity - an ideal basis for reaching a higher energy density.

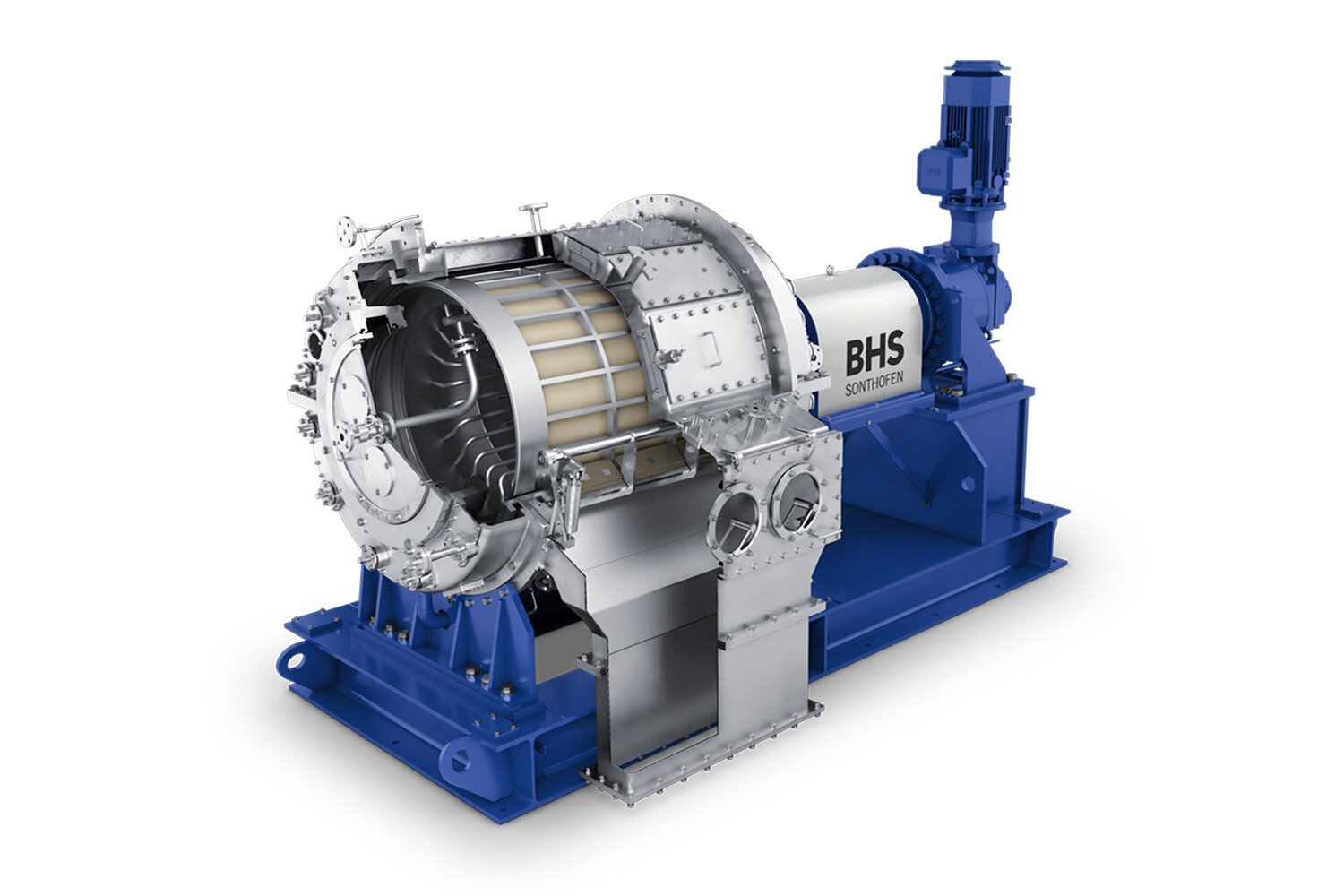

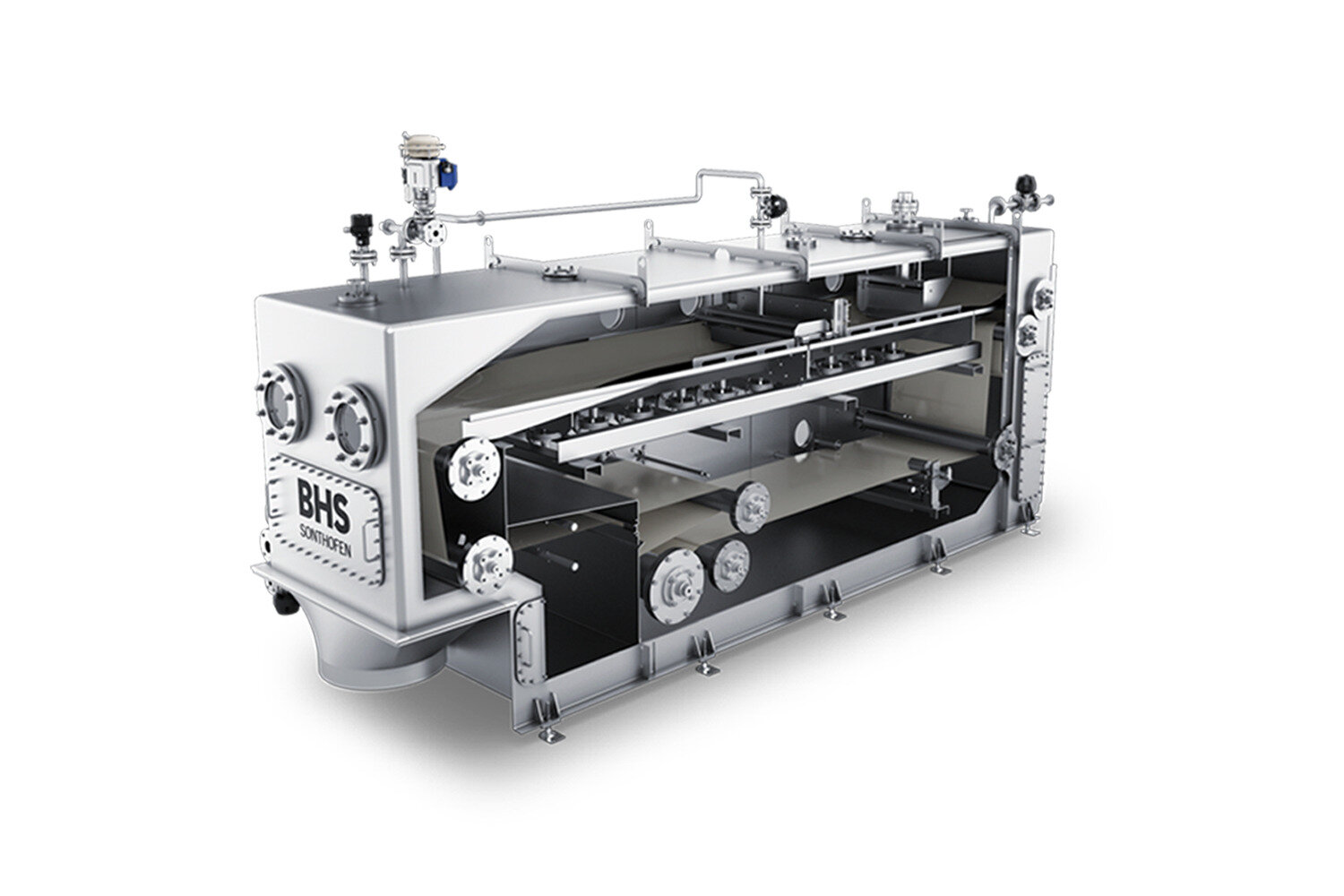

Economical high temperature treatment

Economical high temperature treatment

In high-temperature applications, energy efficiency plays a crucial role. The BHS battery reactors contribute to a profitable production process with economical heating technologies and advanced insulation. BHS has consistently adapted its high-temperature technology to the requirements of battery mass production. Even processes in the uppermost temperature range can be carried out with uniform heat distribution. This means a significant increase in product homogeneity in the BHS high-temperature dryer compared to conventional technologies.

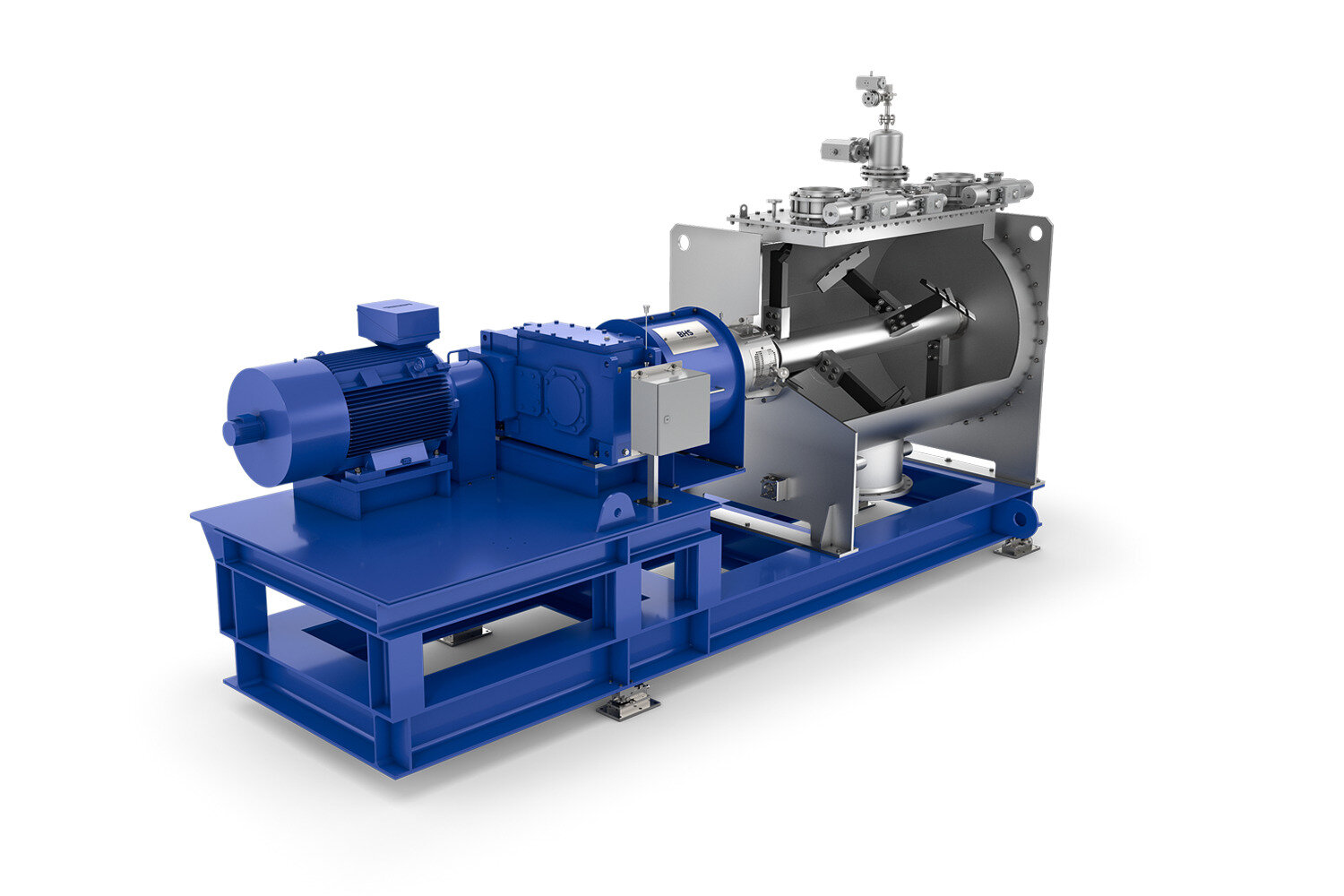

Intensive mixing

Intensive mixing

BHS high-performance mixers are used for mixing of battery base mixes. Here, filter cake, additive powders, and liquids are intensively mixed. The horizontal mixers are made of stainless steel and equipped with a CIP cleaning system. The proven BHS agitator contains adjustable shovels, which, depending on the task, allow a wall clearance of between 1 mm and 25 mm. Separately driven choppers ensure agglomerate-free mixing. A lip seal or liquid-lubricated, double mechanical seal ensures optimal shaft sealing.