Processing toxic waste

Processing toxic waste

Toxic materials are often disposed of in steel drums, big bags and similar types of containers. This is done to minimize the number of spills and discharges into the environment. SMP systems turn the toxic material into a pumpable mass, which can then be fed into an incinerator, for example. Thanks to our technical expertise and highly efficient solutions, our offering includes the design and construction of SMP plants.

Fast, efficient shredding

Processing whole steel drums

Processing whole steel drums

The machine used must be durable, low-wear and powerful in order, for example, to process steel drums filled with 200 liters of viscous toxic material. Designed as a low-speed, high-torque twin-shaft crusher, the BHS rotary shear (type VR) is the perfect choice to meet the challenge. The unit optimally shreds bulky feed material for further downstream processing.

Preparation for combustion

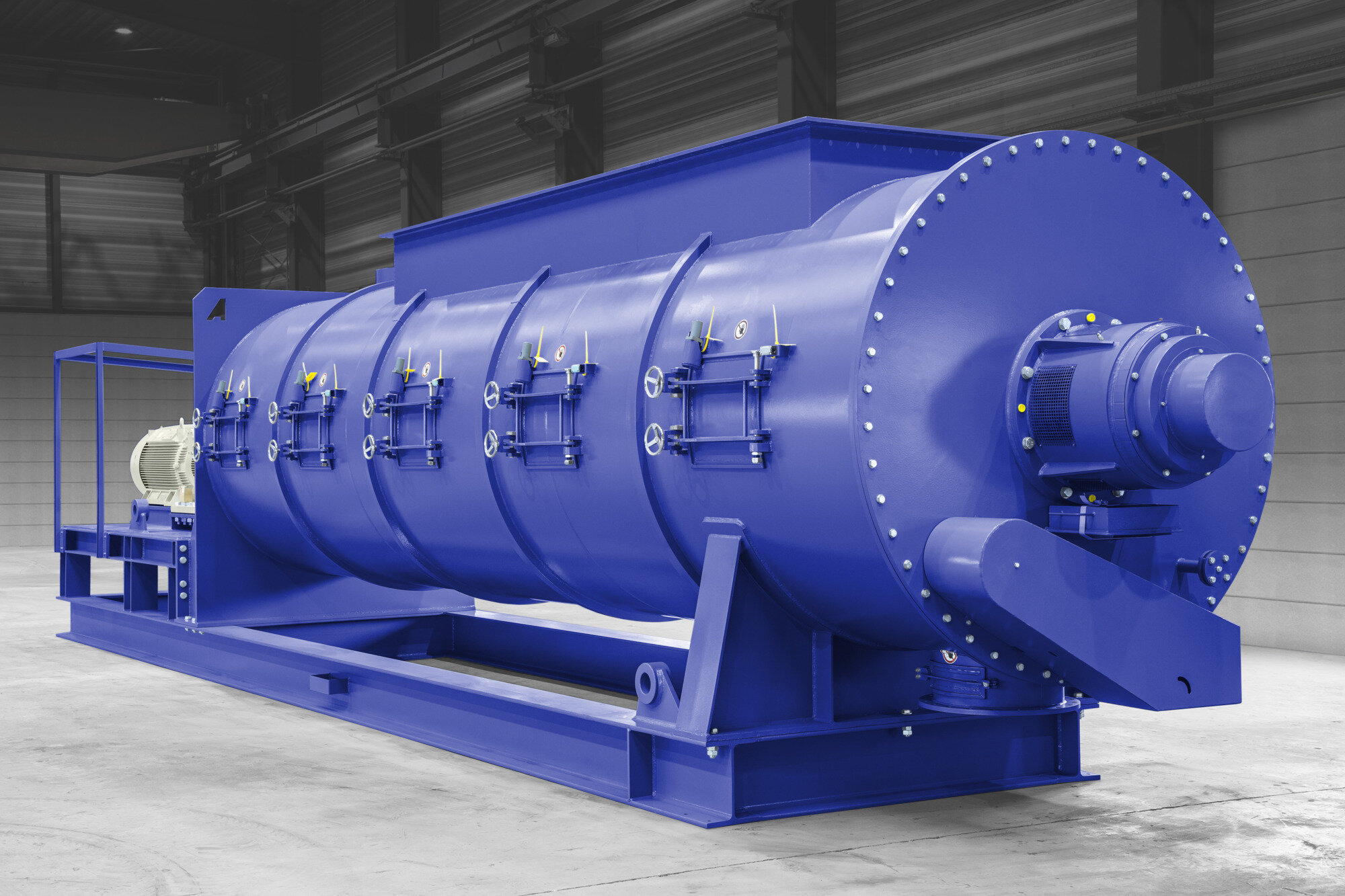

Homogenization of the mixing material

Homogenization of the mixing material

To turn the shredded material into a pumpable, combustible mixture, we use the horizontal mixer in continuous operation. As a result, the material is not only optimally mixed in the shortest time possible, but additives can also be added and evenly distributed to facilitate pasteurization and speed up the combustion process. This creates the conditions necessary for optimum pumpability and combustibility.