RAPAX

RAPAX – The new, universal pre-shredder

RAPAX – The new, universal pre-shredder

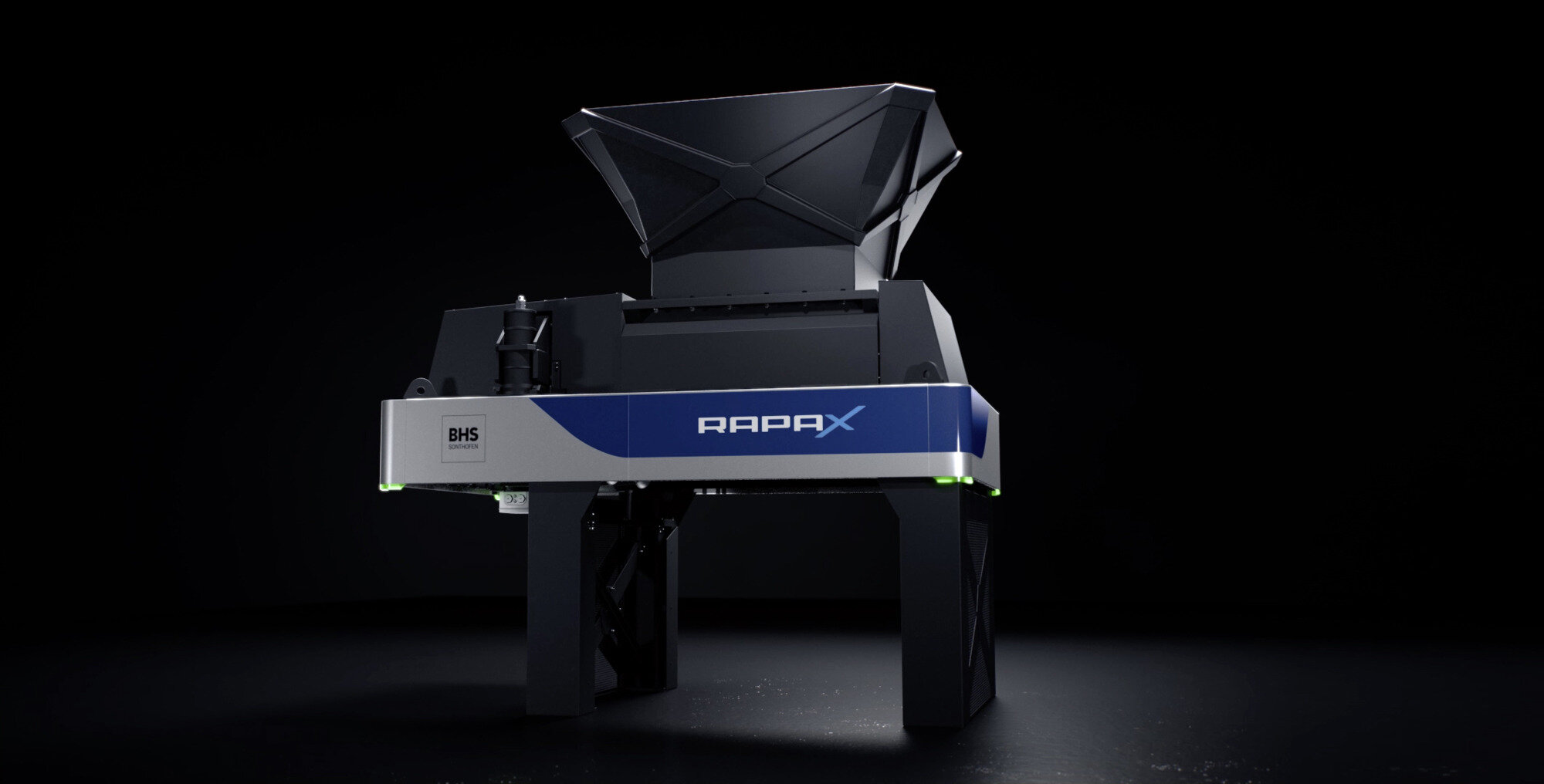

For more than 100 years, BHS-Sonthofen has been developing, optimizing and building robust and innovative shredding machines that are individually adapted to the conditions at hand. RAPAX was developed in close collaboration with an industrial designer. The aim was to outfit this innovative technology with an intelligent design and to add functional design elements that make RAPAX more resistant and easier to maintain. The result is a completely redesigned state-of-the-art pre-shredder. The extremely robust, high-torque machine represents a new solution that takes pre-shredding to a new level. BHS-Sonthofen’s RAPAX raises the bar in pre-shredding technology.

Powerful design and performance.

Thanks to its inspiring design and various groundbreaking technical innovations, the robust, high-torque RAPAX raises pre-shredding to a new level. Since enormous forces are at work during pre-shredding, the development team placed particular emphasis on a robust design. The slow-running, two-shaft pre-shredder offers a wide range of applications in the recycling industry by supporting different tool variations, shredding table inserts and various adjustable parameters. Extensive testing and innovative design details make it ideally suited for metal recovery, commercial and industrial waste processing and construction waste recycling.

In order to be able to optimally process a multitude of different feed materials, RAPAX is available in different designs and sizes. It is available in the 15xx or 20xx series that comes in three different sizes each, with shaft lengths ranging between 1.2 and 3.2 meters.

Highlights

Intelligent detailed solutions combined with design

Intelligent detailed solutions combined with design

Drive powers [1]

Even the highest demands on shredding forces place no limits on the RAPAX with drive powers of up to 400 kW. This guarantees reliable, high throughput even under the most adverse conditions.

Shock resistant [2]

BHS has set a new benchmark in gearbox-saving technology. The combination of belt drive and planetary gear in a compact design with the bearing of the drive unit on rubber buffers can effectively protect the drive unit against shocks and constraining forces. For a significantly increased service life of the gear unit.

Strong and modern engineering [3]

A structurally very robust machine design with state-of-the-art engineering results in maximum robustness. This is one of the key factors why the RAPAX can be used in a very wide range of applications.

Hydraulic pusher unit [4]

A hydraulic pusher device is available as an option. It ensures continuous material infeed when processing low-density, light or bulky feed stock.

Individual configurations [5]

Depending on the application, the RAPAX can be individually configured. In addition to the model size, various tearing tables as well as electric or hydraulic drives are available. Furthermore, two different shredding tools in terms of geometry and design can be equipped. The wear-optimized "JANUS-Shape" masters heavy applications, while the throughput-optimized "BAT-Shape" scores top grades in light applications.

Less downtime guaranteed [6]

The RAPAX features a split machine housing and unique BHS shaft changing system for quick and convenient replacement of the tearing shafts. This allows a fast and efficient tool exchange that is perfectly adapted to the application and the grain size of the output material.

Intelligent control system

The shafts can be controlled completely flexibly via the machine control system. Synchronous and asynchronous movements are just as possible as reversing ones. The RAPAX is designed to shred material in every running direction. The control system makes it possible to select the appropriate program consisting of different movement sequences for every input material. Optimal conditions for a wide range of feed materials.

Fields of application

Technical systems

Unique shaft changing system

Unique shaft changing system

The unique BHS shaft changing system ensures a quick and convenient exchange of the tearing shafts, thus allowing operators to efficiently change the tool and perfectly adapt RAPAX to the application and particle sizes of the feed material. This ensures minimum downtimes. Once the infeed hopper has been removed, the tearing shafts equipped with a quick coupling system are accessible for easy shaft replacement. The quick coupling is screw-fastened, so the shafts can be changed without having to disassemble the gearbox. As a result, the tearing shafts can be removed without any problems.

Durable drive unit thanks to technology that protects the gears

Durable drive unit thanks to technology that protects the gears

Each shaft of the RAPAX unit is powered independently, either electrically or hydraulically. In either case, the drive system consists of standard industrial drives and a variable speed controller. BHS sets new standards by combining a belt drive with planetary gear and mounting the entire drive unit on rubber buffers in order to provide effective long-term protection against impacts and constraining forces. This gear protection technology designed by BHS significantly increases the service life of the gearbox.

The electrical drive is also available in a broad power range to cater to the specific customer and feed material requirements: up to 400 kW can be installed on request.

Tearing table and shafts offer numerous configuration options

Tearing table and shafts offer numerous configuration options

Depending on the feed material and the application, different tearing tables and tearing tools are available to ensure our customers can perfectly configure the RAPAX unit according to their requirements. Thanks to the different tearing tables and a large assortment of tools, the output size of the feed material can be adjusted with pinpoint accuracy. Two shredding tools with an optimized geometry and design are available for equipping the tearing shaft. The tearing table, which is designed as a one-piece cassette, is located beneath the two tearing shafts and can also be removed or exchanged in the shaft exchange system.

Wear optimized: “JANUS Shape”

Wear optimized: “JANUS Shape”

The wear-optimized and robust “JANUS Shape” shredding tool can handle massive, heavy feed material as commonly occurs, for example, in the preliminary shredding of metal fractions or construction waste.

Optimized throughput: “BAT Shape”

Optimized throughput: “BAT Shape”

Owing to its special geometry and design, the strongly serrated “BAT Shape” model delivers higher throughput, especially when processing light feed materials such as commercial waste and light scrap.

Technical specifications

Performance data

| TYPE | Drive power | Rotor speed (max.) | Rated torque | Rotor diameter | Number of tearing tools |

|---|---|---|---|---|---|

| RAPAX 1512 | 150 - 220 kW | 40 rpm | 28.000 - 42.000 Nm | 700 mm | 4 / 5 |

| RAPAX 1516 | 180 - 264 kW | 40 rpm | 34.000 - 50.000 Nm | 700 mm | 7 / 9 |

| RAPAX 1522 | 220 - 264 kW | 40 rpm | 42.000 - 50.000 Nm | 700 mm | 10 / 12 |

| RAPAX 2022 | 220 - 320 kW | 40 rpm | 42.000 - 58.000 Nm | 950 mm | 9 / 12 |

| RAPAX 2028 | 320 - 400 kW | 40 rpm | 58.000 - 67.000 Nm | 950 mm | 11 / 15 |

| RAPAX 2032 | 320 - 400 kW | 40 rpm | 58.000 - 67.000 Nm | 950 mm | 12 / 16 |

All specifications apply to the standard design. Technical data for customized designs may differ from the specified data. All technical data may change due to development. Subject to modification without notice.

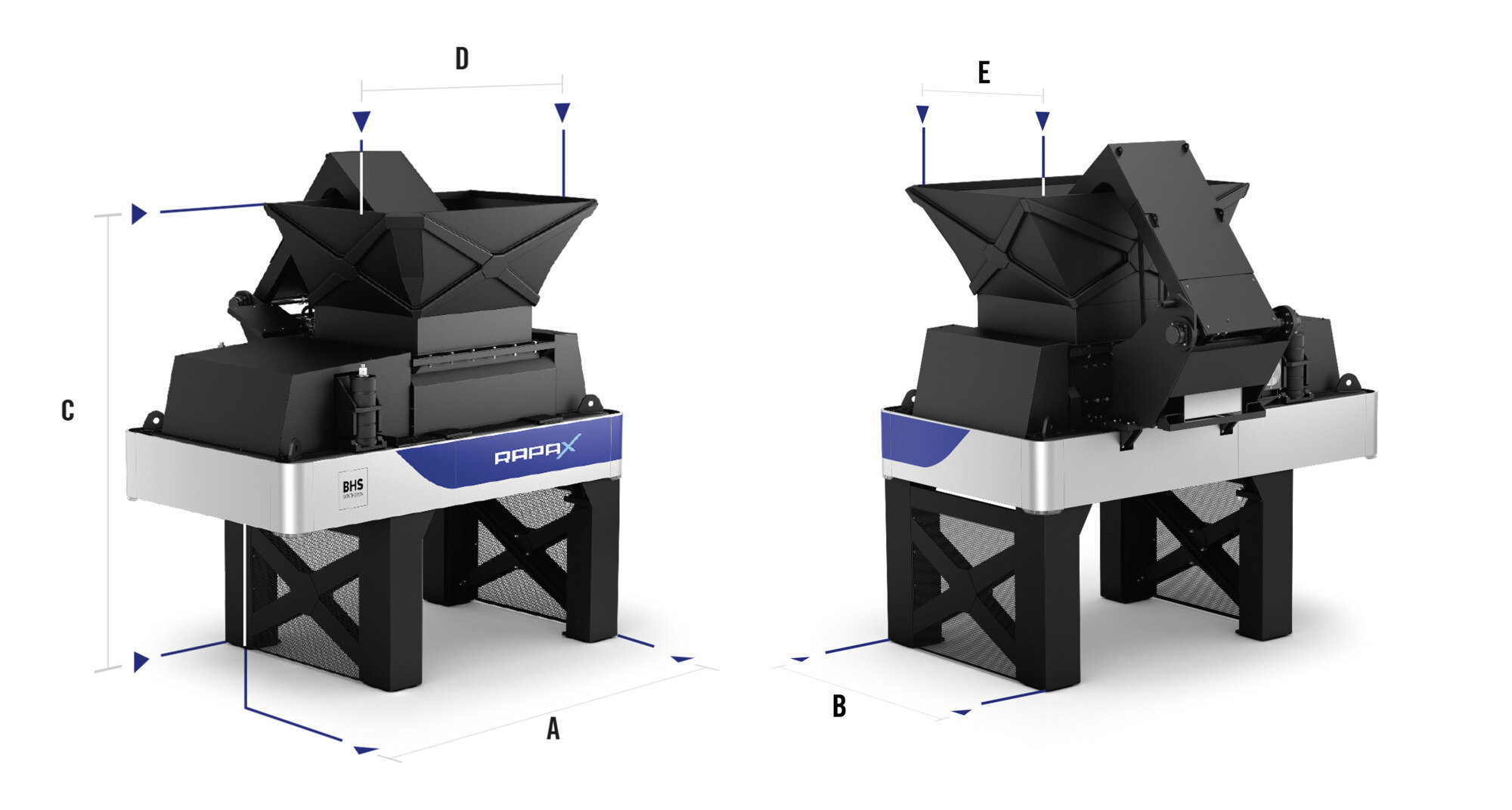

Dimensions and weights

| TYPE | A | B | C | D | E | Working chamber (length x width) | Weight |

|---|---|---|---|---|---|---|---|

| RAPAX 1512 | 4.300 mm | 2.700 mm | 4.700 mm | 2.400 mm | 2.000 mm | 1.500 x 1.200 mm | 22 tons |

| RAPAX 1516 | 4.700 mm | 2.700 mm | 4.700 mm | 2.800 mm | 2.000 mm | 1.500 x 1.600 mm | 25 tons |

| RAPAX 1522 | 5.300 mm | 2.700 mm | 4.700 mm | 3.400 mm | 2.000 mm | 1.500 x 2.200 mm | 30 tons |

| RAPAX 2022 | 5.500 mm | 3.200 mm | 5.200 mm | 3.400 mm | 2.500 mm | 2.000 x 2.200 mm | 38 tons |

| RAPAX 2028 | 6.100 mm | 3.200 mm | 5.200 mm | 4.000 mm | 2.500 mm | 2.000 x 2.800 mm | 45 tons |

| RAPAX 2032 | 6.500 mm | 3.200 mm | 5.200 mm | 4.400 mm | 2.500 mm | 2.000 x 3.200 mm | 50 tons |

All specifications apply to the standard design. Technical data for customized designs may differ from the specified data. All technical data may change due to development. Subject to modification without notice.

RAPAX with dimension markings