High-quality surfaces and large product variety

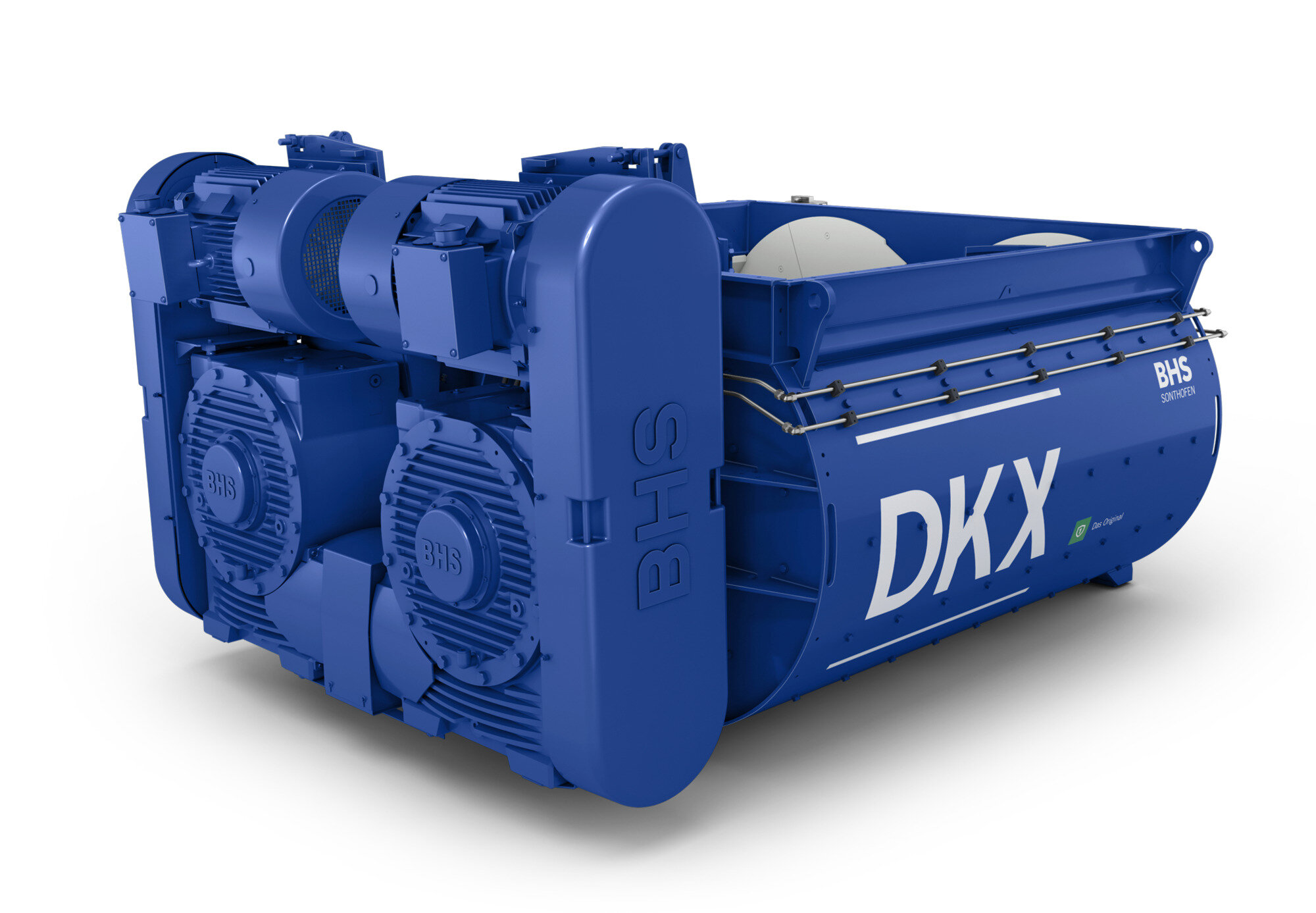

You need a mixer that allows you to produce high-quality surfaces and reduce the number of rejects? We have the answer! When it comes to producing paving stones, rely on the twin-shaft batch mixer (DKX). After all, it is particularly important for the top layer that structural additives and colors are mixed to perfection.

Improved quality – Fewer rejects

Improved quality – Fewer rejects

The driveway and parking lot are often the first things you notice when making a house call. It is therefore no wonder that many companies and homeowners attach importance to attractive pavements. In the production of concrete paving stones, aesthetics are just as important as functionality. The proven three-dimensional mixing principle developed by BHS reduces optical defects to a minimum, resulting in fewer rejects and more satisfied customers.

The pressure is on to make your mixer shine

The pressure is on to make your mixer shine

For the production of concrete blocks, we recommend a mixer equipped with an integrated high-pressure cleaning system. Uncomplicated cleaning between two batches with different formulations virtually eliminates carryover. This reduces the number of rejects and guarantees reproducible results. Further optional equipment: adapted speed, precise moisture measurement and water metering as well as smooth mixing tools.

Video

Twin-shaft batch mixer (DKX) for the production of concrete paving blocks

Twin-shaft batch mixer (DKX) for the production of concrete paving blocks

Smooth mixing unit, three-dimensional mixing principle and maximum reliability: Efficiency and quality go hand in hand at BHS. The mixer is the key component in the production of concrete paving blocks. Our proven twin-shaft batch mixer can adapt flexibly to your needs and requirements and mix even small batches reliably. Watch the video to learn more about the twin-shaft batch mixer (DKX) in use at the concrete block factory of Excluton.